What Is Plastic Deformation Of Metal Yena Engineering

What Is Plastic Deformation Of Metal Yena Engineering Deformation of materials can be defined as macroscopic changes to the size and shape of materials under the effect of mechanical loading, thermal loading or phase transformation, etc. from a mechanical point of view, it is possible to classify deformation into two as elastic and plastic deformation. A definite shape change or plastic deformation occurs before the rupture. the ductile fracture process comes with massive energy absorption. hence, the required energy for a ductile fracture is higher than the need for a brittle fracture. the tensile test of metal components can be an indicator for the observation of the fracture types.

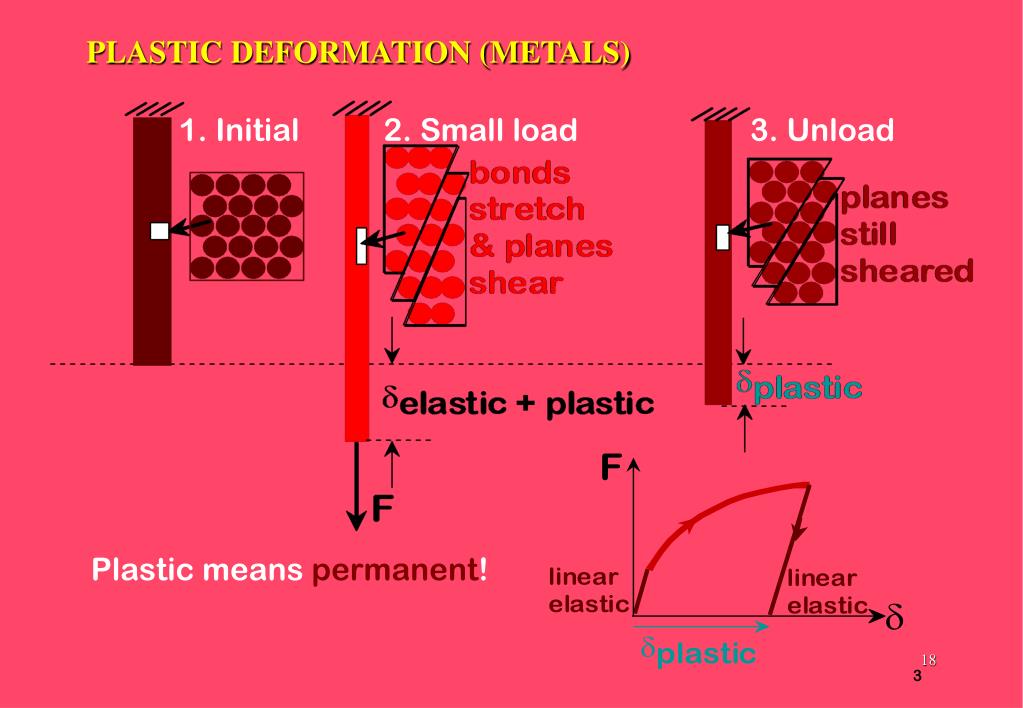

What Is Plastic Deformation Of Metal Yena Engineering A representation of fracture types can be seen below figure. the first schematic represents the fracture of very ductile or soft metals where necking is obvious. the second schematic illustrates the moderate ductile fracture with an average plastic flow. the final schematic can only be seen in brittle materials. figure 2. Plastic deformation is the permanent distortion that occurs when a material is subjected to tensile, compressive, bending, or torsion stresses that exceed its yield strength and cause it to elongate, compress, buckle, bend, or twist. figure 6.2 shows schematics of these deformation mechanisms. The theory of plastic deformation of metal is applied in two fields. (1) solving the strength problem of metal, including basic research and application design. (2) discussing plastic processing, solving the relationship between the applied force and deformation conditions, and solving the change of material properties after plastic deformation. The plastic deformation may occur under the tensile, compressive or torsional stresses. it is a function of stress, temperature and rate of straining. there are two basic modes of plastic deformation, namely: slip or gliding and twining. the slip mode is common in many crystal at ambient and elevated temperatures.

Ppt Chapter 6 Mechanical Properties Powerpoint Presentation Free The theory of plastic deformation of metal is applied in two fields. (1) solving the strength problem of metal, including basic research and application design. (2) discussing plastic processing, solving the relationship between the applied force and deformation conditions, and solving the change of material properties after plastic deformation. The plastic deformation may occur under the tensile, compressive or torsional stresses. it is a function of stress, temperature and rate of straining. there are two basic modes of plastic deformation, namely: slip or gliding and twining. the slip mode is common in many crystal at ambient and elevated temperatures. The plastic deformation occurs in steels during metal forming processing such as rolling, forging, high pressure torsion, etc. which modify mechanical properties of materials through the grain refinement, and the shape change of objects. several phenomena in the scope of plastic deformation, such as hardening, recovery, and recrystallization are of great importance in designing. Plastic deformation is the irreversible and permanent deformation of materials when the stress on the materials exceeds a certain value. with plastic deformation, we can not only process materials into required shapes, but also improve the properties of metal materials (see plastic working of metal). the macroscopic mechanical properties of.

What Is Plastic Deformation Definition Slip And Twinning Causes The plastic deformation occurs in steels during metal forming processing such as rolling, forging, high pressure torsion, etc. which modify mechanical properties of materials through the grain refinement, and the shape change of objects. several phenomena in the scope of plastic deformation, such as hardening, recovery, and recrystallization are of great importance in designing. Plastic deformation is the irreversible and permanent deformation of materials when the stress on the materials exceeds a certain value. with plastic deformation, we can not only process materials into required shapes, but also improve the properties of metal materials (see plastic working of metal). the macroscopic mechanical properties of.

Comments are closed.