Vol 20 Pressure Relief Safety Devices Evomart

Vol 20 Pressure Relief Safety Devices Evomart Volume 20. pressure relief & safety devices. last month’s volume 19 covered liquid refrigerant receivers. the containment of refrigerant in vessels and refrigerant lines demands that safety be given due consideration to eliminate risk to persons due to refrigerant release or explosion and to minimise refrigerant losses thereby avoiding. Knowing the set pressure and capacity of the relief device, the length of discharge piping for each pipe size can be calculated from the code formula: 9 p 2 d 5. l = ¾¾¾. c 2. where. l = length of discharge pipe or tube in feet (m) p = 0.25 [ (set pressure x 1.1) 14.7] d = internal diameter of pipe or tube in inches (mm).

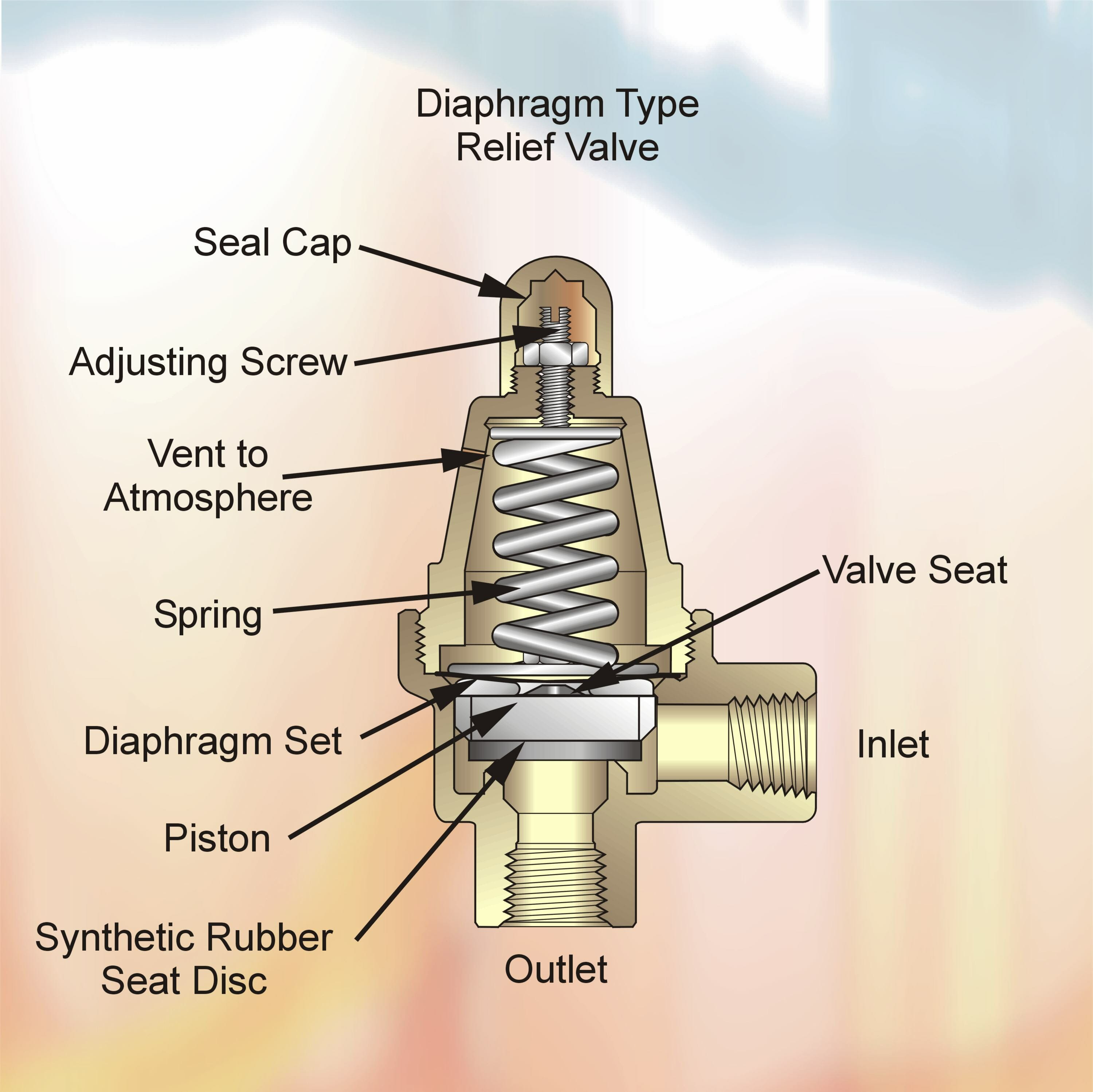

Vol 20 Pressure Relief Safety Devices Evomart Next month: volume 20 – pressure relief & safety devices used in the vapour compression refrigeration cycle. disclaimer: whilst every effort is made to ensure absolute accuracy, business edge ltd will not accept any responsibility or liability for direct or indirect losses arising from the use of the data contained in this series of articles. Pressure relief devices are used to provide a means of venting excess pressure which could rupture a boiler or pressure vessel. a pressure relief device is the last line of defense for safety. if all other safety devices or operating controls fail, the pressure relief device must be capable of venting excess pressure. 2. types of devices. • temperature and pressure safety relief valve— this device is typically used on potable water heaters. in addition to its pressure relief function, it also includes a temperature sensing element which causes the device to open at a predetermined temperature regardless of pressure. the set temperature on these devices is usually 210°. Pressure safety valves. this device is commonly known as a “pop valve” because it opens completely and rapidly when the pressure exceeds the setpoint. the valve will remain open until the process pressure drops to approximately 95% of set pressure. these valves are mostly used for gas and steam. figure 1 2.

Comments are closed.