Using Ttt Diagrams To Predict The Microstructures Of Steel

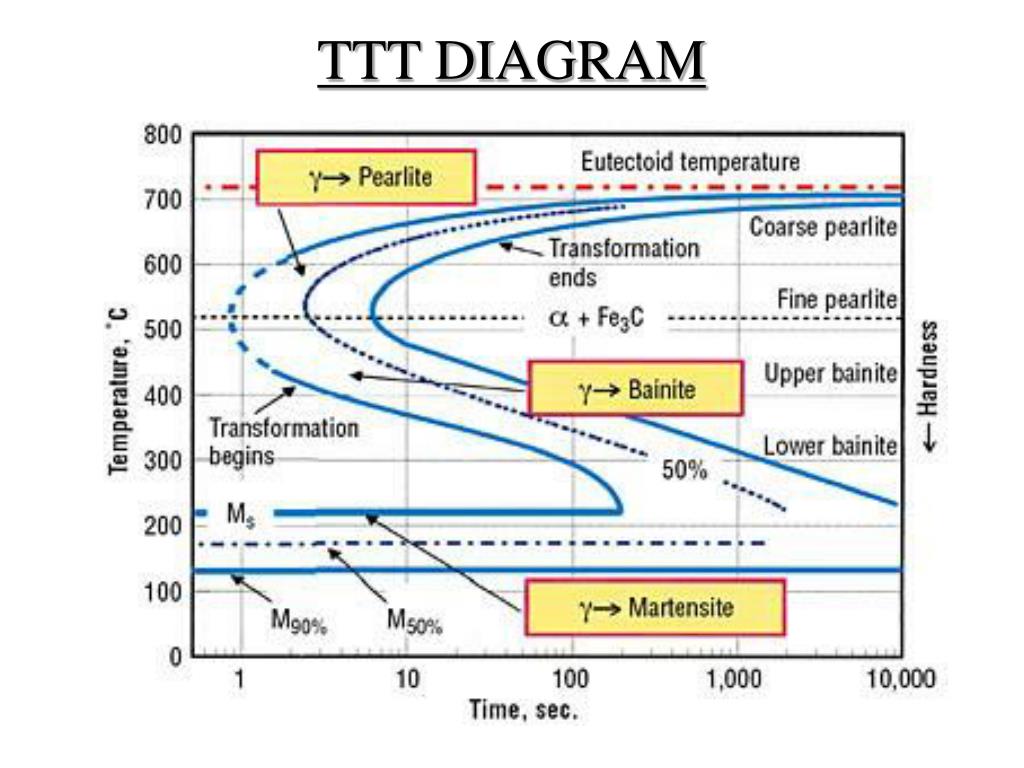

Understanding The Ttt Diagram For 1045 Steel A Comprehensive Guide Ttt diagrams can tell us what steel microstructures we will get. pearlite, bainite, martensite, spheroidite, or tempered martensite. the diagrams can also te. Figure 1b. ttt diagram and microstructures obtained by different types of cooling rates. figure 1c. ttt diagram and microstructures result. the microstructure of the material is significantly altered as the cooling rate increases. by heating and cooling a series of samples, the history of the austenite transformation may be recorded.

Using Ttt Diagrams To Predict The Microstructures Of Steel Youtube The kinetics of transformation are better illustrated using a time temperature transformation (ttt) diagram as illustrated in fig. 4. there are two "c" curves, the top one for reconstructive transformations and the lower one for displacive transformations. also illustrated are schematic microstructures within individual austenite grains. Transformations using a time temperature transformation (ttt) diagram (3, 4) for each steel composition. these diagrams have been developed for many compositions using several approaches (5). the dark line on the left represents the start of transformation (defined as 1% transformed) while the dark line on the right represents the. To predict new ttt diagram with high efficiency and low costs, researchers proposed several computational methods based on existing diagrams and theoretical models, such as empirical formulas of ms, ac1 and ac3 [15], [16], and calculating the incubation periods by phase transformation thermodynamic method and kinetic method [17], [18], [19]. Time temperature transformation (ttt) diagrams can show phase transformation sequence for microstructures with respect to time and temperature, and are hence important for the design of stainless steel [5], [6], [7]. therefore, accurate prediction of ttt diagrams is very important for promoting the development of stainless steel.

Diagram Welding Ttt Diagram Wiringschema Com To predict new ttt diagram with high efficiency and low costs, researchers proposed several computational methods based on existing diagrams and theoretical models, such as empirical formulas of ms, ac1 and ac3 [15], [16], and calculating the incubation periods by phase transformation thermodynamic method and kinetic method [17], [18], [19]. Time temperature transformation (ttt) diagrams can show phase transformation sequence for microstructures with respect to time and temperature, and are hence important for the design of stainless steel [5], [6], [7]. therefore, accurate prediction of ttt diagrams is very important for promoting the development of stainless steel. Which ttt diagrams are used are steels, alloys, [2 ] metallic glasses, [3 , 4 ] glasses, and glass ceramics. [5–9 ] they all have in common that their history of phase formation is dependent on their cooling rate. a primary ttt diagram was produced for steel to predict the formation and existence of martensite and. Determination of ttt diagram for eutectoid steel davenport and bain were the first to develop the ttt diagram of eutectoid steel. they determined pearlite and bainite portions whereas cohen later modified and included m s and m f temperatures for martensite. there are number of methods used to determine ttt diagrams. these are salt bath (figs. 1.

Diagram Ttt Dan Ctt Teknik Mesin Which ttt diagrams are used are steels, alloys, [2 ] metallic glasses, [3 , 4 ] glasses, and glass ceramics. [5–9 ] they all have in common that their history of phase formation is dependent on their cooling rate. a primary ttt diagram was produced for steel to predict the formation and existence of martensite and. Determination of ttt diagram for eutectoid steel davenport and bain were the first to develop the ttt diagram of eutectoid steel. they determined pearlite and bainite portions whereas cohen later modified and included m s and m f temperatures for martensite. there are number of methods used to determine ttt diagrams. these are salt bath (figs. 1.

Comments are closed.