Understanding The Five Principles Of Lean Lbspartners

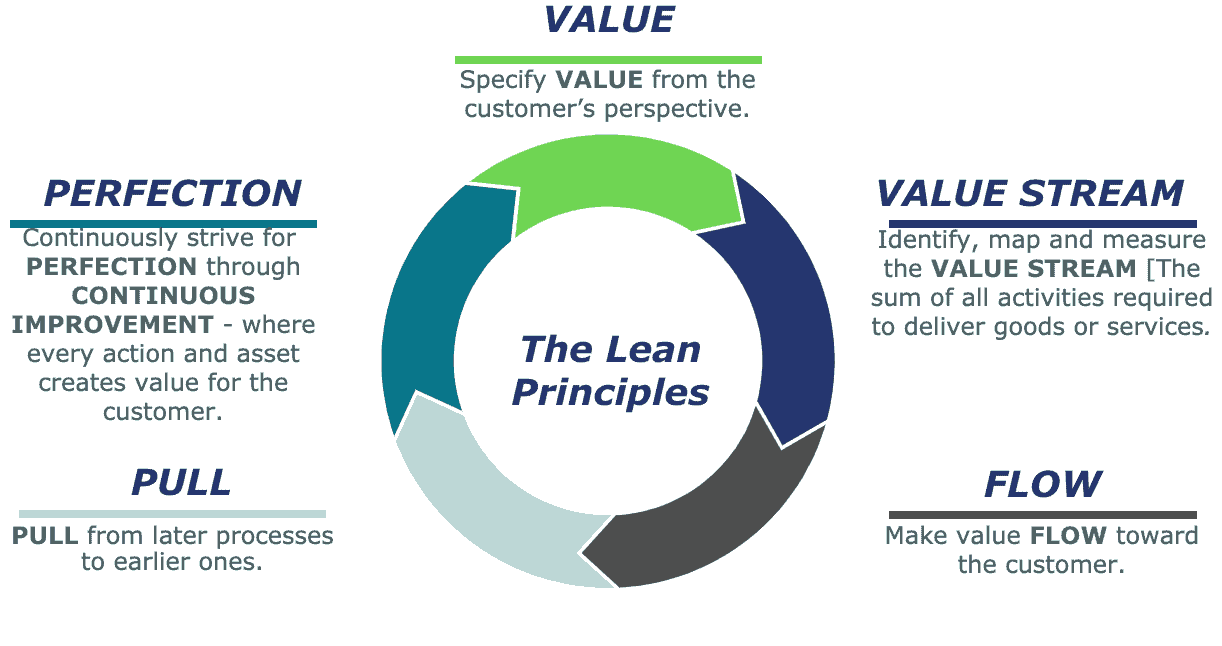

Understanding The Five Principles Of Lean Lbspartners Lean fosters continuous improvement while keeping respect for people at the centre of its ethos. the primary principles of lean originate in the book “the machine that changed the world” by daniel roos, james p. womak, and daniel t. jones. below we will discuss the five principles at the centre of lean that are used to improve efficiency in. The lean principles. lean is defined as a methodology which maximises value for the customer by eliminating waste from a company’s activities. below, we will identify the five lean principles to provide a path for the implementation of lean thinking and continuous improvement within an organisation. these are stated as: value. value stream. flow.

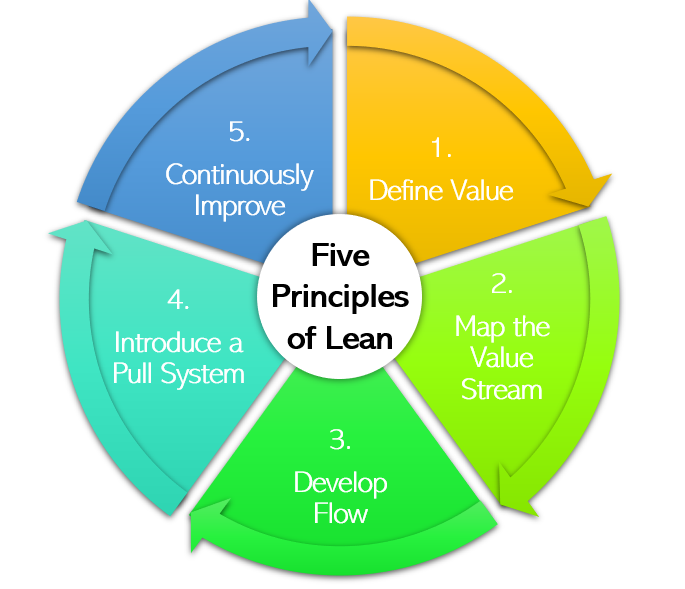

Understanding The Five Principles Of Lean Lbspartners Vrogue Co Why irish medical and pharmaceutical companies must understand the five principles of lean. ireland punches far above its weight in the manufacture of medical devices, medical equipment, and medicines. The five principles are considered a recipe for improving workplace efficiency and include: 1) defining value, 2) mapping the value stream, 3) creating flow, 4) using a pull system, and 5) pursuing perfection. the next sections provides a detailed overview of each principle. the five lean principles explained: figure 1. the five lean principles. James p. womack understanding your customer's needs is the cornerstone of lean. we help you delve deep into what your customers truly value, enabling you to tailor your processes to meet and. The five principles of lean. the five principles of lean are: specify value from the standpoint of the end customer. identify all the steps in the value stream, eliminating whenever possible those steps that do not create value. make the value creating steps occur in tight sequence so the product will flow smoothly toward the customer.

Comments are closed.