Types Of Casing In Drilling Oilfield Wells Drilling Manual

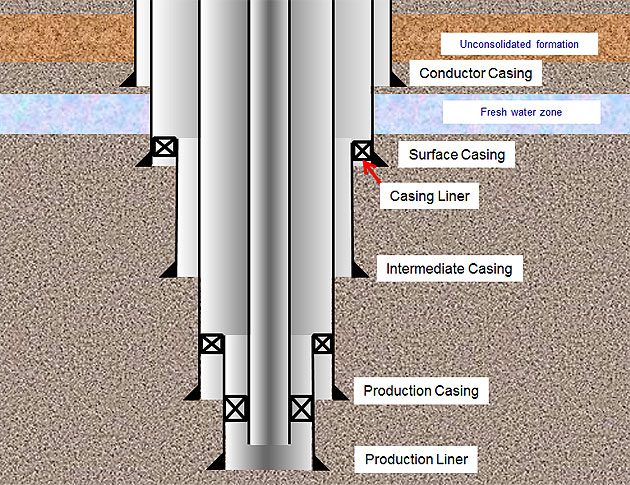

Types Of Casing In Drilling Oilfield Wells Drilling Manual Surface casing. this type of casing, which is used in drilling wells, serves several purposes: to protect shallow freshwater sands from possible contamination; to prevent cave in of unconsolidated, weaker, near surface sediments and in the event of a kick. to allow the flow to be contained by the blowout preventers. Casing pipe applications. casing pipes are placed in a wellbore for the following reasons: supporting the weight of the wellhead and bop stack. providing a return path for mud to surface when drilling. isolating high pressure zones from the wellbore. controlling well pressure by containing downhole pressure.

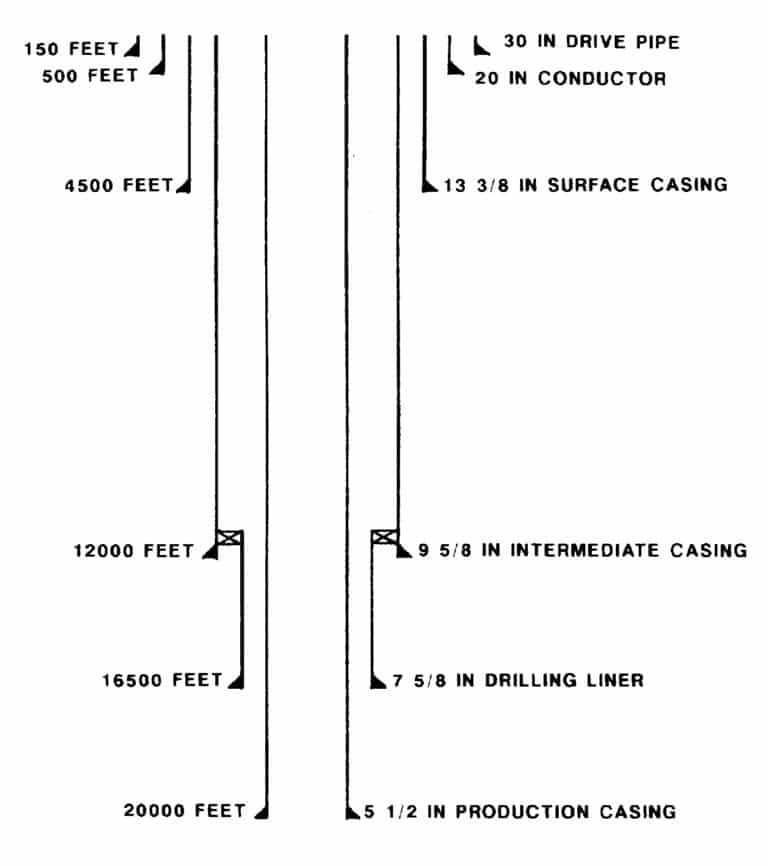

Types Of Casing In Drilling Oilfield Wells Drilling Manual This connection has a metal to metal seal for superior leak resistance. an internally threaded coupling with internal shoulders provides positive makeup torque and a non turbulent bore (see figure 6). also, due to its superior joint and bending strength, it is used as the completion casing liner (one of the types of casing) for horizontal wells. %pdf 1.6 %âãÏÓ 42 0 obj > endobj 77 0 obj > filter flatedecode id[2e15d31ebf333949a35e898d749cfe3f>60ea8c0436e0f74cb3ca834c35111233>] index[42 71] info 41 0 r. The choice of casing size depends on factors such as the depth, pressure, and formations being drilled through. the standard casing sizes include 7 inch, 9 5 8 inch, and 13 3 8 inch, but other sizes may also be used depending on the specific well design. Formation and reaming existing hole while drilling casing in place. a new style drillout pdc was used to drill through the casing bit and continue drill ing formation without tripping for a new bit . the authors will make cost comparisons with offset wells drilled with conventional drilling systems and focus on lessons learned . spe iadc 105432.

Introduction To Casing Drilling Course The choice of casing size depends on factors such as the depth, pressure, and formations being drilled through. the standard casing sizes include 7 inch, 9 5 8 inch, and 13 3 8 inch, but other sizes may also be used depending on the specific well design. Formation and reaming existing hole while drilling casing in place. a new style drillout pdc was used to drill through the casing bit and continue drill ing formation without tripping for a new bit . the authors will make cost comparisons with offset wells drilled with conventional drilling systems and focus on lessons learned . spe iadc 105432. The drilling manual. developed by one of the world’s leading authorities on drilling technology, the fifth edition of the drilling manual draws on industry expertise to provide the latest drilling methods, safety, risk management, and management practices, and protocols. utilizing state of the art technology and techniques, this edition. Introduction. casing and cementing are essential to drilling oil and gas wells. lining a hole with casing keeps it from caving in after it is drilled, sealing the wellbore from encroaching fluids and gasses. cementing the casing in place ataches it firmly to the wellbore wall and stabilizes the hole.

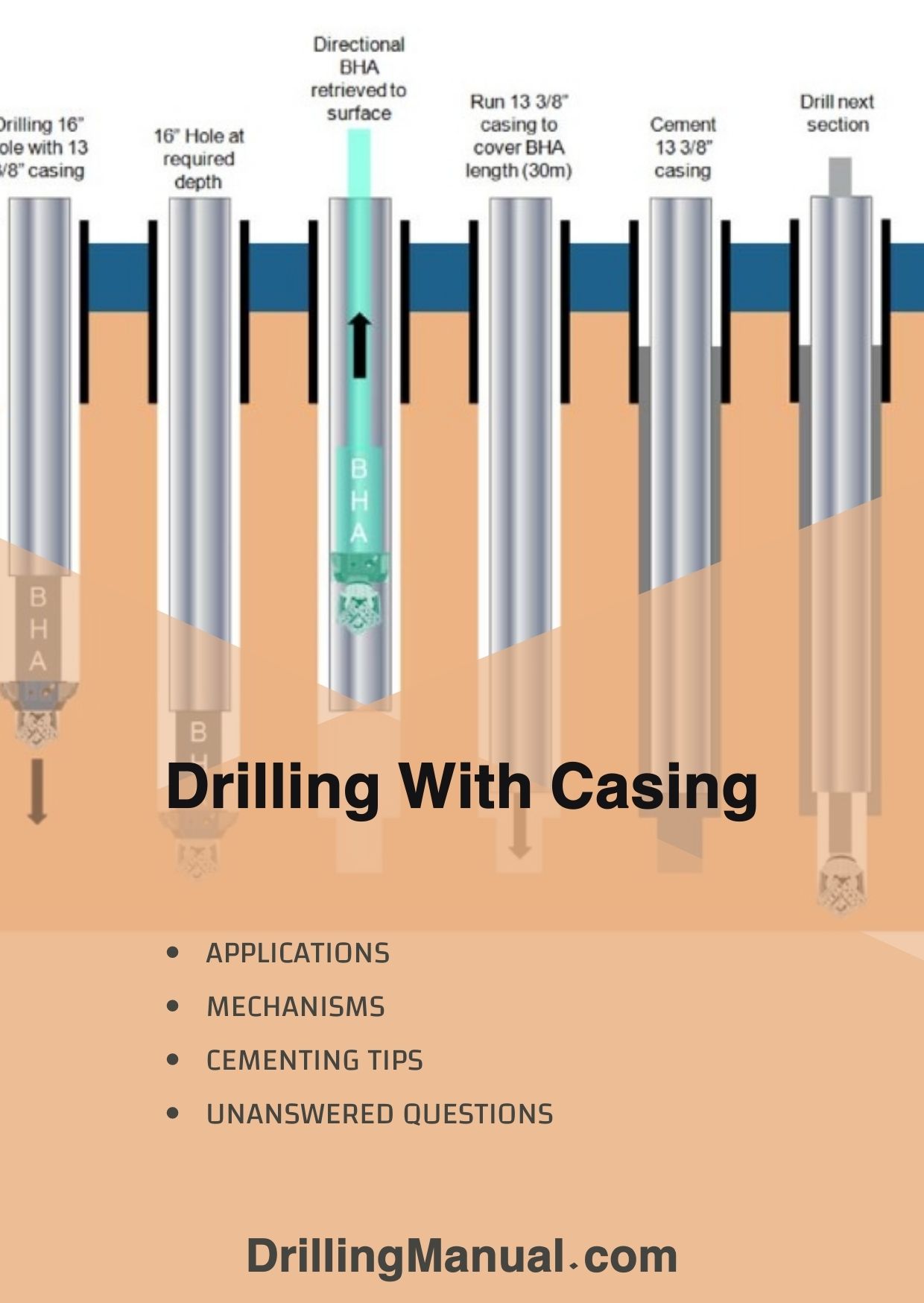

Drilling With Casing How Why Cementing Tips Drilling Manual The drilling manual. developed by one of the world’s leading authorities on drilling technology, the fifth edition of the drilling manual draws on industry expertise to provide the latest drilling methods, safety, risk management, and management practices, and protocols. utilizing state of the art technology and techniques, this edition. Introduction. casing and cementing are essential to drilling oil and gas wells. lining a hole with casing keeps it from caving in after it is drilled, sealing the wellbore from encroaching fluids and gasses. cementing the casing in place ataches it firmly to the wellbore wall and stabilizes the hole.

Comments are closed.