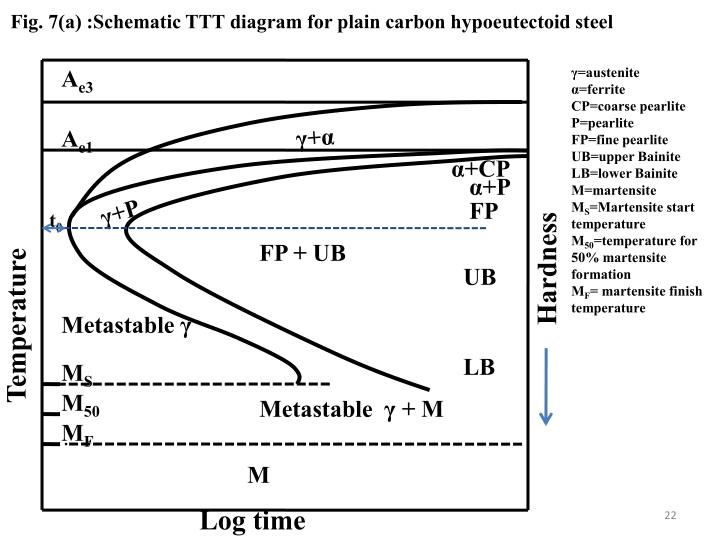

Ttt Diagram Hypoeutectoid Steel

Ttt Diagrams For Steel Youtube Hypoeutectoid steel and by cementite in hypereutectoid steel. schematic ttt diagrams for eutectoid, hypoeutectoid and hyper eutectoid steel are shown in fig.4, figs. 7(a) (b) and all of them together along with schematic fe fe 3 c metastable equilibrium are shown in fig. 8. 21. Animated lecture series on heat treatment [complete course]ttt diagram of hypoeutectoid steel & its solidification mechanism |lecture 2 |part 3| heat treatme.

Ppt Time Temperature Transformation Ttt Diagrams Powerpoint Time temperature transformation (ttt) diagram or s curve refers to only one steel of a particular composition at a time, which applies to all carbon steels. this diagram is also called as c curve isothermal (decomposition of austenite) diagram and bain’s curve. the effect of time temperature on the microstructure changes of steel can be shown. From the cooling paths imposed on the ttt diagram of hypoeutectoid steel, it is apparent for path 1 that the proeutectoid ferrite forms between a 3 and a 1 temperature and holding for a long time it simply equilibrates to produce ferrite and unreacted austenite. however for path 2, the proeutectoid ferrite formation is followed by the complete. A first approximation of the tensile strength of an annealed or normalized hypoeutectoid steel considers the tensile strength of pearlite (800 mpa) and ferrite (300 mpa), as well as the ferrite and pearlite proportions, and applying the lever rule on the fe fe 3 c diagram, the fraction of pearlite (1.30 c 1) and ferrite (1.00–1.30 c 1) in the. Introduction. both temperature & time i.e. rate of cooling is taken in consideration. ttt – time temperature transformation. a plot of temperature versus log of time. steel alloy of definite composition. determines when transformations begin and end for an isothermal (constant temp.) phase transformation of a previously austenitized alloy.

Comments are closed.