Ttt Diagram Basic Ttt Diagram For Steel Eutectoid Steel

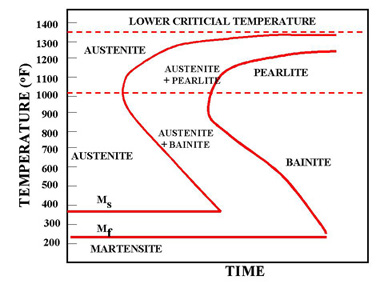

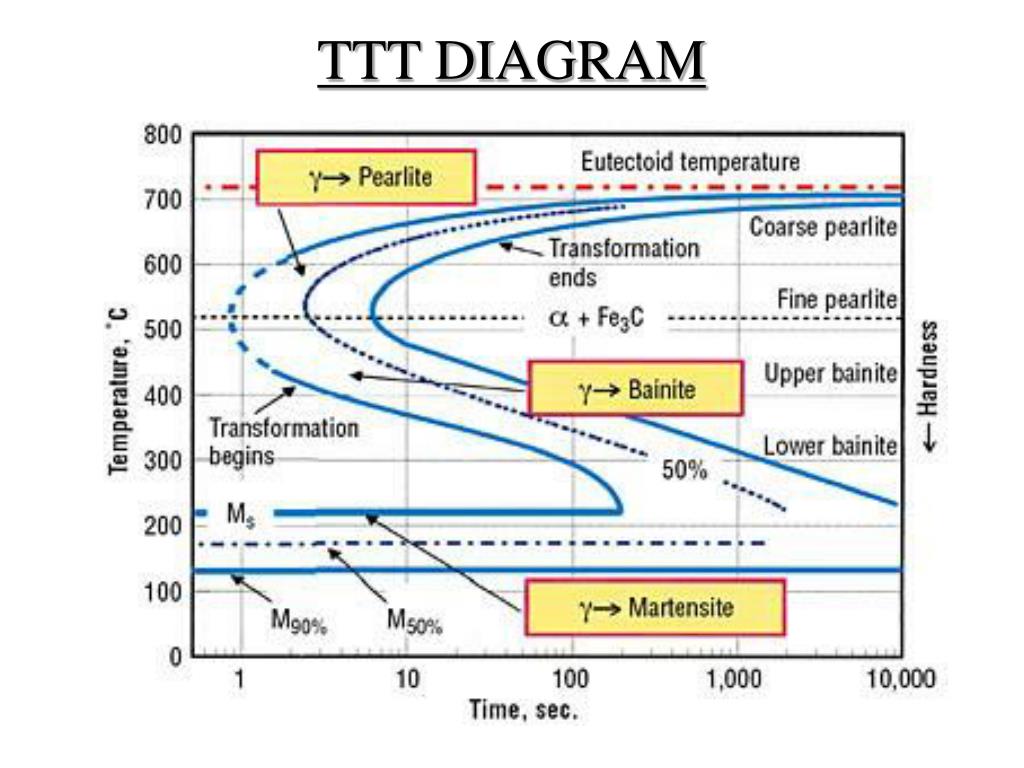

Ttt Diagram Basic Ttt Diagram For Steel Eutectoid Steel Ttt diagram for eutectoid steel ( isothermal transformation diagram ) time temperature transformation (ttt) diagram or s curve refers to only one steel of a particular composition at a time, which applies to all carbon steels. this diagram is also called as c curve isothermal (decomposition of austenite) diagram and bain’s curve. The time temperature transformation (ttt) diagram is an important tool in metallurgy for understanding the transformation behavior of materials. it provides valuable information about the relationship between temperature, time, and the resulting microstructure of a material. the ttt diagram specifically applies to eutectoid steel, which is a.

Ttt Diagram For Steel Introduction. both temperature & time i.e. rate of cooling is taken in consideration. ttt – time temperature transformation. a plot of temperature versus log of time. steel alloy of definite composition. determines when transformations begin and end for an isothermal (constant temp.) phase transformation of a previously austenitized alloy. Getting real: the ttt diagram. here is the "official" isothermal ttt diagram for eutectoid carbon steel. it is not all that different from the unofficial ttt diagram for the pure iron above, except that the γ → α transformation temperature is now at 723 oc (1333 o f). look up the phase diagram if you wonder about this. Time temperature transformation (ttt ) diagram. t (time) t (temperature) t (transformation) diagram is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. it is used to determine when transformations begin and end for an isothermal (constant temperature) heat treatment of a previously austenitized alloy. Such diagram for eutectoid steel is shown in figure 6. it is found that pearlite and bainite transformation overlap and from the nose of the ttt curve at about 550 °c upward, pearlitic reaction takes place; below 450 °c, bainitic transformation is certain.

Martensite Metallurgy For Dummies Time temperature transformation (ttt ) diagram. t (time) t (temperature) t (transformation) diagram is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. it is used to determine when transformations begin and end for an isothermal (constant temperature) heat treatment of a previously austenitized alloy. Such diagram for eutectoid steel is shown in figure 6. it is found that pearlite and bainite transformation overlap and from the nose of the ttt curve at about 550 °c upward, pearlitic reaction takes place; below 450 °c, bainitic transformation is certain. Diagram of eutectoid steel (i.e. steel containing 0.8% c). austenite is stable above eutectoid temperature 727 °c. when steel is cooled to a temperature below this eutectoid temperature, austenite is transformed into its transformation product. ttt diagram relates the transformation of austenite to time and temperature conditions. Mechanical engineering questions and answers. 1. using the ttt diagram for eutectoid steel, specify the constituents and their approximate percentages of a small specimen subjected to the following time temperature treatments. all begin with a completely austenized specimen: rapidly cool to 650°c, hold for 100 seconds, then quench to room.

Diagram Welding Ttt Diagram Wiringschema Com Diagram of eutectoid steel (i.e. steel containing 0.8% c). austenite is stable above eutectoid temperature 727 °c. when steel is cooled to a temperature below this eutectoid temperature, austenite is transformed into its transformation product. ttt diagram relates the transformation of austenite to time and temperature conditions. Mechanical engineering questions and answers. 1. using the ttt diagram for eutectoid steel, specify the constituents and their approximate percentages of a small specimen subjected to the following time temperature treatments. all begin with a completely austenized specimen: rapidly cool to 650°c, hold for 100 seconds, then quench to room.

Ttt Diagram For Eutectoid Steel Wiring Diagram Pictures

Comments are closed.