The Principles Of Lean Think Different

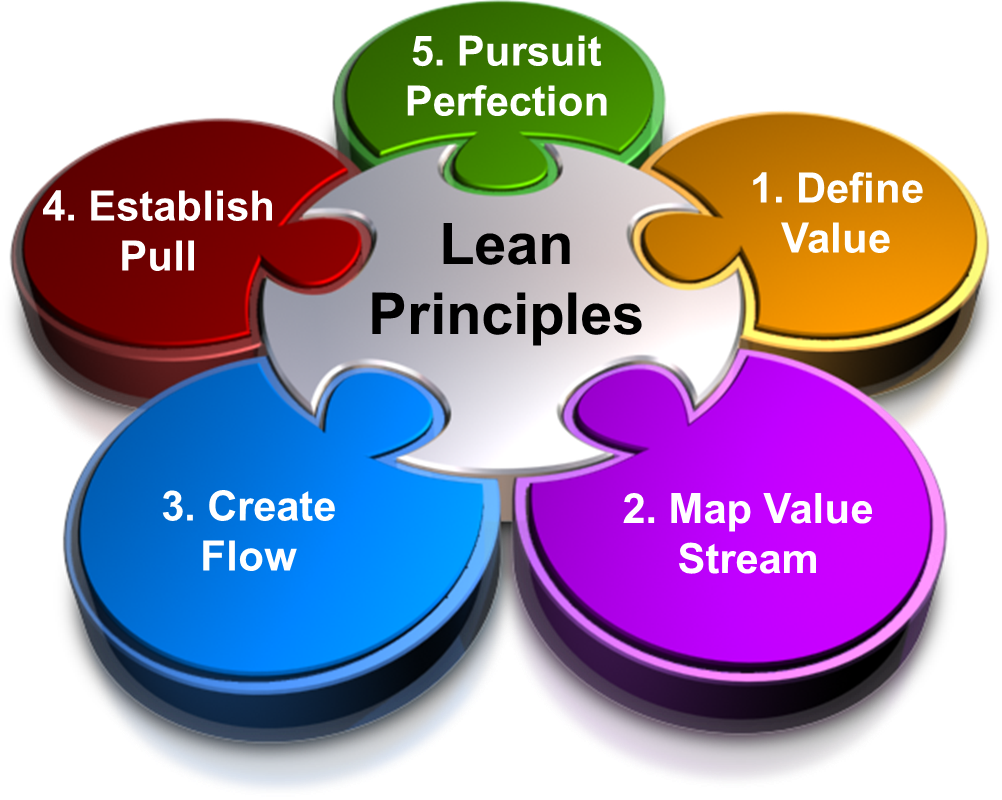

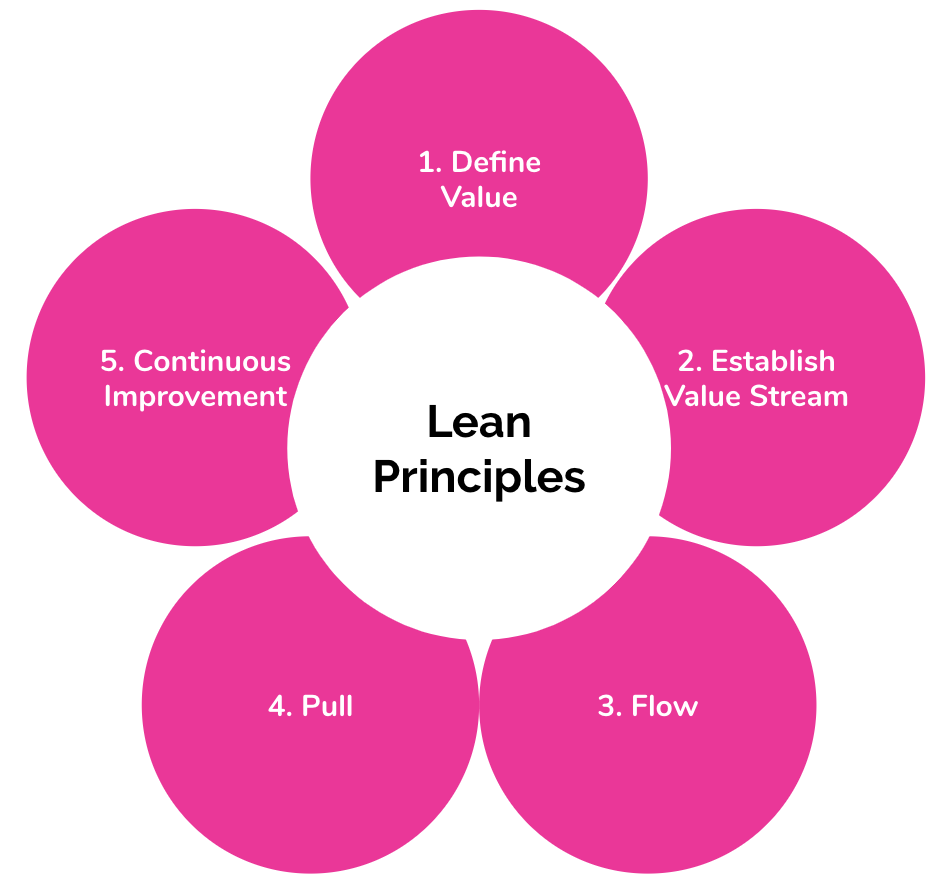

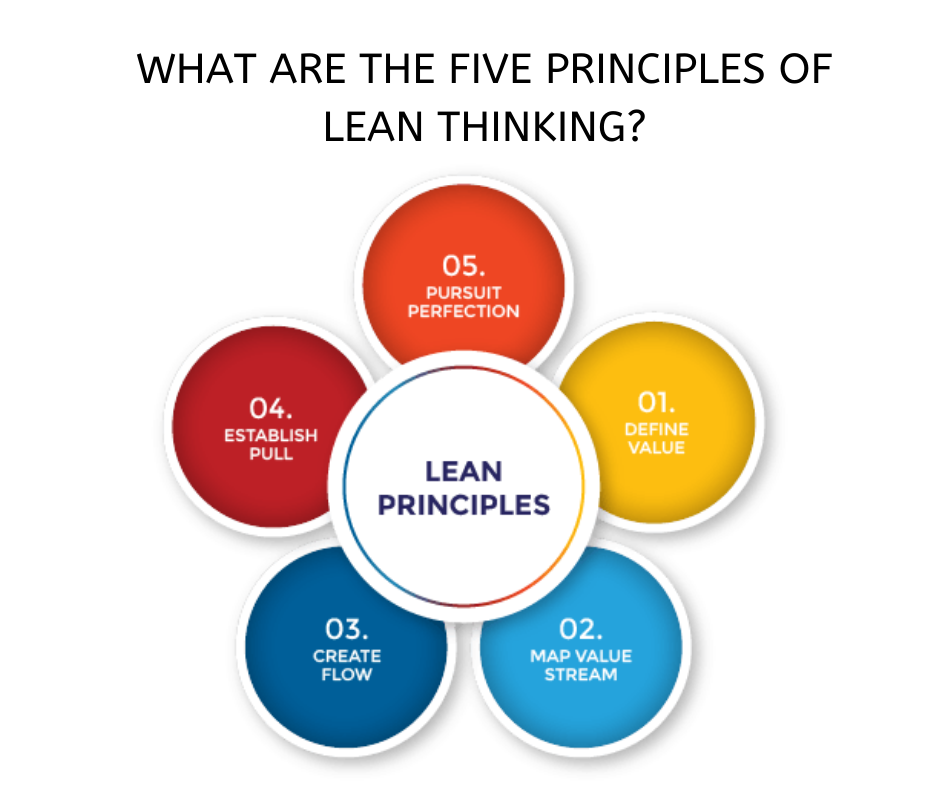

The Principles Of Lean Think Different Lean came about as a result of manufacturing but has since been adopted in many workplaces and management systems. the principles of lean encourage continuous improvement and focus on respect for all members of a team. the main five principles to improve efficiency in work practices include: defining value. mapping out the value stream. The five principles are considered a recipe for improving workplace efficiency and include: 1) defining value, 2) mapping the value stream, 3) creating flow, 4) using a pull system, and 5) pursuing perfection. the next sections provides a detailed overview of each principle. the five lean principles explained: figure 1. the five lean principles.

The Principles Of Lean Think Different The five principles of lean. the five principles of lean are: specify value from the standpoint of the end customer. identify all the steps in the value stream, eliminating whenever possible those steps that do not create value. make the value creating steps occur in tight sequence so the product will flow smoothly toward the customer. Waiting. non utilized talent. transportation. inventory. motion and extra processing. there is also the concept of lean enterprise, which expands the ideology to the entire value stream or supply chain. lean manufacturing and enterprise ideally work together to reach the fullest expression of the lean philosophy. Anastasia worked in management consulting and tech startups, so she has lots of experience in helping professionals choosing the right business software. the 5 principles of lean management include 1) define value, 2) map the value stream, 3) create flow, 4) establish pull, and 5) constant improvement. The lean principles originated from the toyota production system (tps), these principles are clear sets of guidelines and techniques aimed at improving processes, minimizing waste, and therefore resulting in an overall increase in customer value. the five principles of lean are: 1. to identify value, 2. mapping the value stream, 3.

The Principles Of Lean Think Different Riset Anastasia worked in management consulting and tech startups, so she has lots of experience in helping professionals choosing the right business software. the 5 principles of lean management include 1) define value, 2) map the value stream, 3) create flow, 4) establish pull, and 5) constant improvement. The lean principles originated from the toyota production system (tps), these principles are clear sets of guidelines and techniques aimed at improving processes, minimizing waste, and therefore resulting in an overall increase in customer value. the five principles of lean are: 1. to identify value, 2. mapping the value stream, 3. The first of the lean thinking principles is value, which begs organizations to really understand what value means for their customers. once you identify value, you can provide it! value is really the foundation of the five lean thinking principles, and without it, you can’t move on to the next four. 2. value stream. Lean thinking as such is a movement of practitioners and writers who experiment and learn in different industries and conditions, to lean think any new activity. lean production adepts who have interpreted the term "lean" as a form of operational excellence and have turned to company programs aimed at taking costs out of processes.

Lean Thinking Overview Principles And Benefits The first of the lean thinking principles is value, which begs organizations to really understand what value means for their customers. once you identify value, you can provide it! value is really the foundation of the five lean thinking principles, and without it, you can’t move on to the next four. 2. value stream. Lean thinking as such is a movement of practitioners and writers who experiment and learn in different industries and conditions, to lean think any new activity. lean production adepts who have interpreted the term "lean" as a form of operational excellence and have turned to company programs aimed at taking costs out of processes.

What Are The Five Principles Of Lean Thinking By Shreya Shinde Medium

Comments are closed.