The Complete Guide To Understanding Cooling Curve Phase Diagrams

The Complete Guide To Understanding Cooling Curve Phase Diagrams The cooling curve phase diagram is a graphical representation of this solidification process, which helps us understand the behavior of different substances during solidification. the cooling curve phase diagram consists of two axes: temperature and time. it shows the temperature of the substance on the y axis and the time on the x axis. By removing the time axis from the curves and replacing it with composition, the cooling curves indicate the temperatures of the solidus and liquidus for a given composition. this allows the solidus and liquidus to be plotted to produce the phase diagram: this page titled 12.5: interpretation of cooling curves is shared under a cc by nc sa.

How To Read A Cooling Curve Youtube The cooling curve method is one of the oldest and simplest methods to determine phase diagrams and phase transition temperatures. this is achieved by recording temperature (t) of a material versus time as it cools from its molten state through solidification (at constant pressure). whenever a phase change takes place in a metal or alloy, the. Interpretation of cooling curves. the melting temperature of any pure material (a one component system) at constant pressure is a single unique temperature. the liquid and solid phases exist together in equilibrium only at this temperature. when cooled, the temperature of the molten material will steadily decrease until the melting point is. D = (cp 2) − (c(p − 1) p) d = c − p 2 (chapter 4.7) (chapter 4.8) where d is the degrees of freedom, c is the number of components, p is the number of phases. the 2 comes from t and p as independent variables. so let’s do a couple of examples where we apply the gibbs phase rule! let’s look at the single component phase diagram. A cooling curve for a sample that begins at the temperature and composition given by point a is shown in figure 8.10.1b 8.10. 1 b. figure 8.10.1 8.10. 1: (a) cooling of a two component system from liquid to solid. (b) cooresponding cooling curve for this process. as the sample cools from point a, the temperature will decrease at a rate.

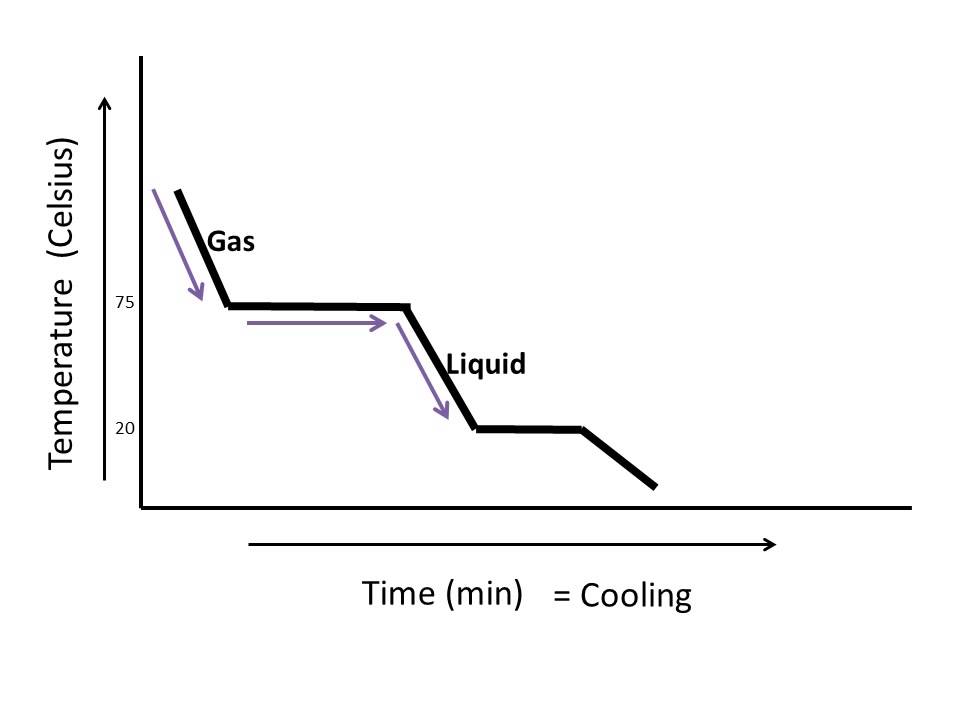

Heating And Cooling Curves вђ Overview Examples Expii D = (cp 2) − (c(p − 1) p) d = c − p 2 (chapter 4.7) (chapter 4.8) where d is the degrees of freedom, c is the number of components, p is the number of phases. the 2 comes from t and p as independent variables. so let’s do a couple of examples where we apply the gibbs phase rule! let’s look at the single component phase diagram. A cooling curve for a sample that begins at the temperature and composition given by point a is shown in figure 8.10.1b 8.10. 1 b. figure 8.10.1 8.10. 1: (a) cooling of a two component system from liquid to solid. (b) cooresponding cooling curve for this process. as the sample cools from point a, the temperature will decrease at a rate. Equilibrium phase diagrams are one of the single most useful tools of a materials scientist and engineer. as maps of the temperature ranges and solubility limits of each known phase in the alloy system, including compounds, they are obviously useful to metal casters, heat treaters and ceramicists and are an invaluable tool in alloy design, in. The experimental set up we imagined would generate a heating curve. heating and cooling curves are graphs. they plot a substance's temperature (y axis) against heat (x axis). for heating curves, we start with a solid and add heat energy. for cooling curves, we start with the gas phase and remove heat energy. cooling and heating curves have five.

Comments are closed.