Sheet Metal Oprations Part 1 Metal Forming Processes

Sheet Metal Oprations Part 1 Metal Forming Processes Youtube It is a type of bending operation, in which a piece of sheet metal is fixed or held between two dies from one end, as shown in the fig. then the other end is forced to strike upon the punch which is free or unfixed. thus, the free or unfixed edge of the sheet metal piece is bent to make the forming process. 2. v bending. "’ Á„5a©€1 þ¨e ˆta Áªhe 1chañ¥ hmÅvq©]lÑÚ%¯?ôm ™yŸ{'dð¥ýøg? ›³ß{Îó|Ïsžåæ € x l™Ù¾d pß ìy sÞÜÅík.

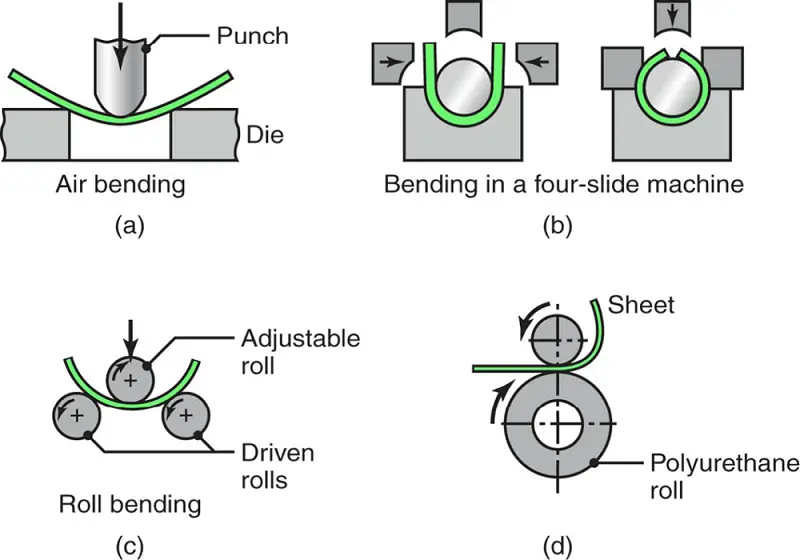

Sheet Metal Operations With Diagrams Sheet forming: sheet metal forming involves forming and cutting operations performed on metal sheets, strips, and coils. the surface area to volume ratio of the starting metal is relatively high. tools include punch, die that are used to deform the sheets. classification of basic sheet forming processes bending deep drawing shearing. By reading this article, you will learn: 1. the techniques and processes involved in sheet metal forming, such as bending, stretching, deep drawing, and hydroforming. 2. the types of materials used, including steel, aluminum, copper, and alloys, and how material properties influence the forming process. 3. Read: the last guide to bulk metal forming you will ever need. let us go through different sheet metal operations shearing, bending, and forming. 1. shearing process. shearing is basically a cutting operation; you can use a shearing machine to cut shear a blank of required dimensions from a larger sheet. 1. the different types of sheet metal forming processes such as bending, stretching, and deep drawing. 2. the materials used in sheet metal forming, including commonly used metals, alloys, and composites. 3. the importance of precision, tolerances, and formability in sheet metal forming.

Sheet Metal Forming Processes And Equipment Machinemfg Read: the last guide to bulk metal forming you will ever need. let us go through different sheet metal operations shearing, bending, and forming. 1. shearing process. shearing is basically a cutting operation; you can use a shearing machine to cut shear a blank of required dimensions from a larger sheet. 1. the different types of sheet metal forming processes such as bending, stretching, and deep drawing. 2. the materials used in sheet metal forming, including commonly used metals, alloys, and composites. 3. the importance of precision, tolerances, and formability in sheet metal forming. Sheet metal forming 1. introduction. key factors. sheet bending outline. sheet metal: metallic sheet typically < 6 mm thick. large surface area volume ratio. applications: auto body parts, beverage cans, utensils. stamped sheet metal part. Chap 2 , sheet metal – p. 1 sheet metal forming processes • involves workpieces with a high ratio of surface area to thickness • plates, thickness > ¼ inch • sheets, thickness ≤ ¼ inch • typical items produced by sheet metal forming processes: metal desks appliance bodies . hubcaps aircraft panels . beverage cans car bodies.

Comments are closed.