Sheet Metal Fabrication Process Sps Ideal Solutions Blog

Sheet Metal Fabrication Process Sps Ideal Solutions Blog Sheet metal fabrication is a process, wherein the metal is converted into a desired shape and size to be fitted into a part or component. there are various welding processes used to fabricate sheet metals, and it is mostly done with the help of press brakes. press brakes are used to form various bends and angles in the metal. To achieve high product quality, only the selection of material would not suffice rather use of the right equipment is important too. this is why you must source sheet metal fabrication services from trusted companies like sps ideal solutions. the company holds over 30 years of experience in sheet metal fabrication and custom product manufacturing.

9 Ways To Cut Down Cost On Metal Fabrication Sps Ideal Solutions Bl 9 ways to save money on metal fabrication. sheet metal fabrication is an important process or one of the production steps in many manufacturing units. it is an important part wherein sheet metals are shaped through cutting, burring, welding, and other techniques to form a part or component of a product. this process though old is now largely. What is sheet metal fabrication? what is it process? want to know, read this guide bit.ly 310czpc #sheetmetalfabrication #metalfabricationprocess. Sheet metal fabrication is a subtractive manufacturing process that forms parts from thin metal sheets. engineers often choose sheet metal parts for their high strength to weight ratio, durability, and versatility. this guide will provide a comprehensive overview of precision sheet metal fabrication techniques, applications, and best practices. By reading this article, you will learn: 1. the techniques and processes involved in sheet metal forming, such as bending, stretching, deep drawing, and hydroforming. 2. the types of materials used, including steel, aluminum, copper, and alloys, and how material properties influence the forming process. 3.

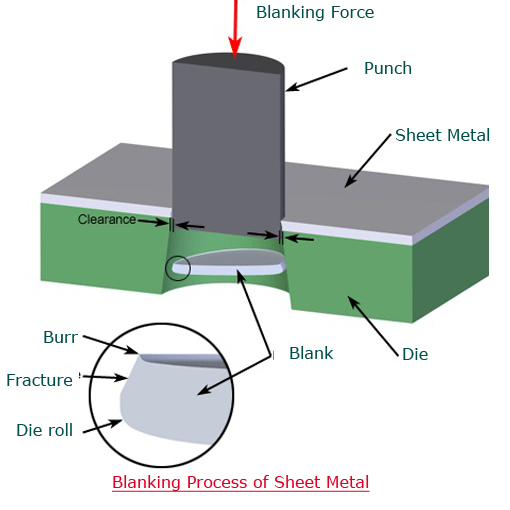

Types Of Custom Metal Fabrication Services Sps Ideal Solutions Blog Sheet metal fabrication is a subtractive manufacturing process that forms parts from thin metal sheets. engineers often choose sheet metal parts for their high strength to weight ratio, durability, and versatility. this guide will provide a comprehensive overview of precision sheet metal fabrication techniques, applications, and best practices. By reading this article, you will learn: 1. the techniques and processes involved in sheet metal forming, such as bending, stretching, deep drawing, and hydroforming. 2. the types of materials used, including steel, aluminum, copper, and alloys, and how material properties influence the forming process. 3. Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. the completion of a product usually comprises of many steps – from cutting and bending to surface treatment and assembling. often times a variety of fabrication techniques can be used to achieve a similar end result. 6. machining in sheet metal fabrication. machining is a critical process in sheet metal fabrication that involves the removal of material from a workpiece to achieve the desired shape and dimensions. unlike forming processes, machining provides high precision and is essential for creating intricate details and features on metal components.

Applications Of Sheet Metal Fabrication Process Pipingmart Blog Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. the completion of a product usually comprises of many steps – from cutting and bending to surface treatment and assembling. often times a variety of fabrication techniques can be used to achieve a similar end result. 6. machining in sheet metal fabrication. machining is a critical process in sheet metal fabrication that involves the removal of material from a workpiece to achieve the desired shape and dimensions. unlike forming processes, machining provides high precision and is essential for creating intricate details and features on metal components.

Comments are closed.