Sheet Metal Fabrication An Introduction And Guide To Fundamental

Guide To Sheet Metal Fabrication Custom Metal Components Assemblies The procedure calls for the utilization of a tool and die, both of which, when subjected to an impact, alter the shape of the metal by applying shear pressure. within the realm of sheet metal fabrication, stamping is a more general phrase. it includes bending, punching, and embossing as well as other processes. The manufacturing & design guide. learn how to effectively design sheet metal parts. this guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting. part 1.

Guide To Sheet Metal Fabrication Custom Metal Components Assemblies Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3d cad files are converted into machine code, which controls a machine to precisely cut and form the sheets into the final part. sheet metal parts are known for their durability, which makes them great for end use applications. 1) use common metal materials to reduce material specifications and control as much as possible within the company’s material manual; 2) in the same product, reduce the variety of materials and sheet thickness specifications as much as possible; 3) under the premise of ensuring the function of the parts, try to use cheap materials, reduce the. Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. the completion of a product usually comprises of many steps – from cutting and bending to surface treatment and assembling. often times a variety of fabrication techniques can be used to achieve a similar end result. Passivation. the sheet metal material is immersed in an acid bath of citric or nitric acid. the acid dissolves the iron but leaves the chromium to form a thick, protective chromium oxide layer. it is used mainly to prevent corrosion on stainless steel materials by creating a protective oxide layer that won’t react with the environment. a.

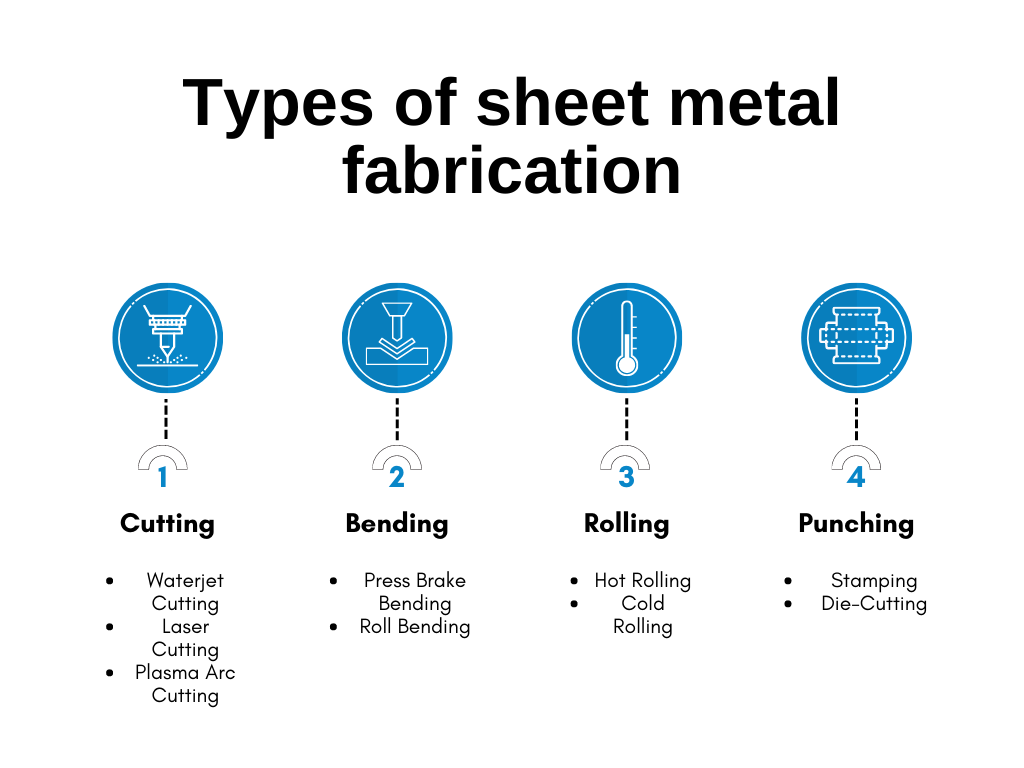

Guide To Sheet Metal Fabrication From Growing Your Business To Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. the completion of a product usually comprises of many steps – from cutting and bending to surface treatment and assembling. often times a variety of fabrication techniques can be used to achieve a similar end result. Passivation. the sheet metal material is immersed in an acid bath of citric or nitric acid. the acid dissolves the iron but leaves the chromium to form a thick, protective chromium oxide layer. it is used mainly to prevent corrosion on stainless steel materials by creating a protective oxide layer that won’t react with the environment. a. Types of sheet metal fabrication techniques. as mentioned above, there are a variety of techniques used during the sheet metal fabrication process. let’s take a closer look at each of them. sheet metal cutting techniques shearing. shearing is one of the most basic and widely used sheet metal cutting techniques. a shear is basically a pair of. In conclusion, this comprehensive guide to sheet metal processing covers a wide range of techniques and methods essential for creating high quality sheet metal components. we have explored various stages of the process, including cutting, forming, bending, joining, and surface treatments. throughout the guide, we have discussed the principles.

An Introduction To Sheet Metal Fabrication Synectic Types of sheet metal fabrication techniques. as mentioned above, there are a variety of techniques used during the sheet metal fabrication process. let’s take a closer look at each of them. sheet metal cutting techniques shearing. shearing is one of the most basic and widely used sheet metal cutting techniques. a shear is basically a pair of. In conclusion, this comprehensive guide to sheet metal processing covers a wide range of techniques and methods essential for creating high quality sheet metal components. we have explored various stages of the process, including cutting, forming, bending, joining, and surface treatments. throughout the guide, we have discussed the principles.

Comments are closed.