Pin On Disk

/Videos and Images/Pin on Disk (POD-4.0) - High Temperature (4x3).png)

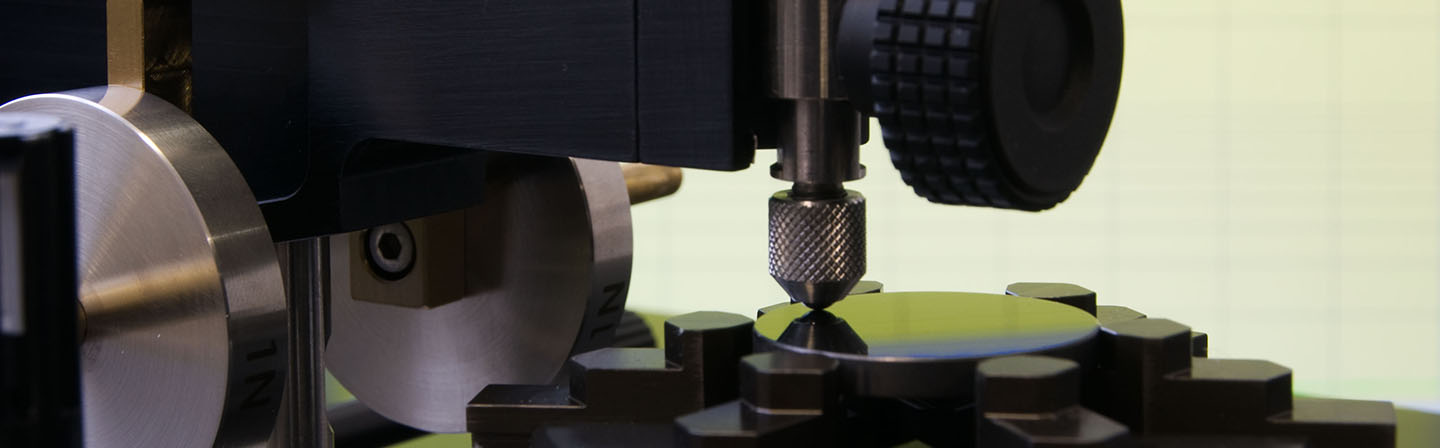

Multi Capability Tribometer Pin Ball On Disk Pin on disk tribometer. schematically, the pin on disk test is depicted in the figure above. the stationary pin is pressed against rotating disk under the given load. the pin can be of any shape, however, the most popular shapes are spherical (ball or lens) or cylindrical due to ease of alignment of such pins (flat pins are typically subject to. The pin on disc system is the most commonly used in dry non abrasive tests [8–10]. it can be used to test composite materials [11] or coatings [12]. this method is helpful for testing lubricants and problems related to lubrication [13, 14]. typically, rounded pin co acted with the disc.

Pin On Disk The pin on disk tests are preferably used to determine two body sliding wear. in pin on disk, the pin is attached with the polymeric material that is slid against the metallic disk or the metallic pin is slid against the disk made of polymer material. sign in to download full size image. figure 13.1. The pin on disk test (din 50324 07, astm g99 05, iso 18535) tribometers can be used to investigate the friction and wear behavior of material pairings. a test material, e.g. a steel ball or a pin, is moved on a circular path over the specimen with a defined standard force (approx. 5 n) (pin on disk). during the test, the friction force or the. Pin on disk wear testing is a method of characterizing the coefficient of friction, frictional force, and rate of wear between two materials. during this tri. Scope. 1.1 this test method covers a laboratory procedure for determining the wear of materials and friction during sliding using a pin on disk apparatus. materials are tested in pairs under nominally non abrasive conditions. the principal areas of experimental attention in using this type of apparatus to measure wear are described.

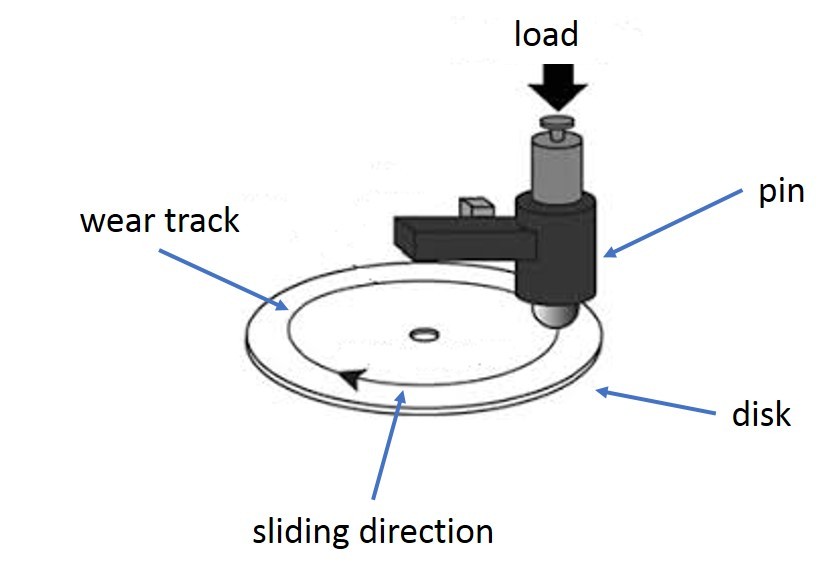

Pin On Disk Tribometer Fig 2 Flat Disk And Spherical Tip Pin Specimen Pin on disk wear testing is a method of characterizing the coefficient of friction, frictional force, and rate of wear between two materials. during this tri. Scope. 1.1 this test method covers a laboratory procedure for determining the wear of materials and friction during sliding using a pin on disk apparatus. materials are tested in pairs under nominally non abrasive conditions. the principal areas of experimental attention in using this type of apparatus to measure wear are described. Pin on disk testing. as outlined by astm g99 04, pin on disk testing consists of a rotating disk in contact with a fixed pin with a spherical top. a schematic is shown below. in these experiments, the user typically has the ability to control and measure the applied normal load, unidirectional speed or oscillation frequency, and environmental. Test specimens and sample preparation note 1—f is the normal force on the pin, d is the pin or ball diameter, d is the disk diameter, r is the wear track radius, and w is the rotation velocity of the disk. fig. 1 schematic of pin on disk wear test system pressure, contact geometry, removal of wear debris, and presence of corrosive environment.

Schematic Functioning Of A Pin On Disk Test Download Scientific Diagram Pin on disk testing. as outlined by astm g99 04, pin on disk testing consists of a rotating disk in contact with a fixed pin with a spherical top. a schematic is shown below. in these experiments, the user typically has the ability to control and measure the applied normal load, unidirectional speed or oscillation frequency, and environmental. Test specimens and sample preparation note 1—f is the normal force on the pin, d is the pin or ball diameter, d is the disk diameter, r is the wear track radius, and w is the rotation velocity of the disk. fig. 1 schematic of pin on disk wear test system pressure, contact geometry, removal of wear debris, and presence of corrosive environment.

Tribometer About Tribology

Comments are closed.