Open Loop Cooling Tower

Open Loop Cooling Tower Schematic Learn how open circuit cooling towers work and compare them with closed circuit cooling towers. delta cooling towers is a manufacturer of high quality, durable cooling towers with a 20 year warranty. Learn the advantages and disadvantages of open and closed loop cooling towers for hydronic systems that require heat rejection. find out how to choose the best type of cooling tower based on application, cost, efficiency, and maintenance.

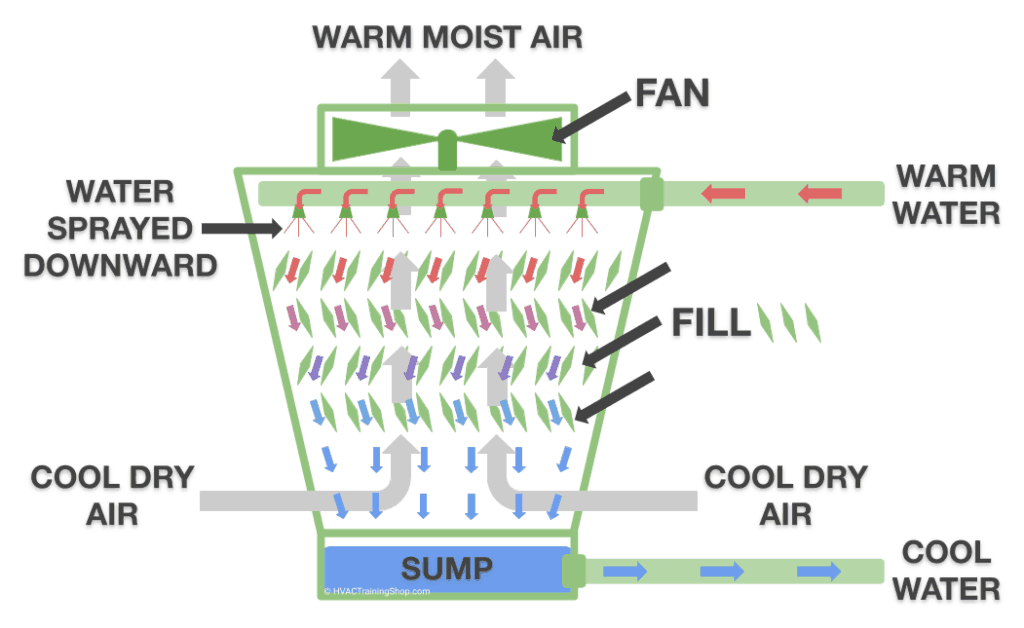

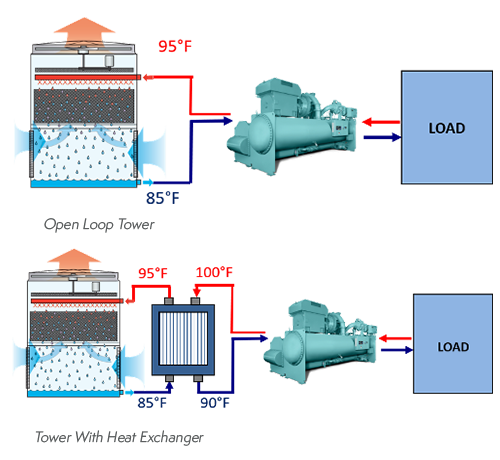

Open Loop Cooling Towers Whaley Products Incorporated Learn the differences between closed circuit and open circuit cooling towers, how they operate, and their advantages and disadvantages. closed circuit towers are used for water cooled heat pumps and open circuit towers are used for hvac cooling. 2. lower cooling tower approach: with an open loop cooling tower, a lower approach can be achieved easily. it must be noted that in an open loop cooling tower we need to count two approaches one with the cooling tower and another with the heat exchanger. in the case of the lower approach, the open loop cooling tower shall be beneficial. 3. In open loop and closed loop cooling towers, the fill media facilitates the contact between air and the water surface. this media helps the water spread into thin, flowing layers, maximizing the surface area exposed to the air flow. fill media is typically made from materials such as polypropylene, wood, or pvc. Cooling towers play a critical role in maintaining the temperature of industrial and commercial operations. but understanding the different types of cooling towers, their functions, and their benefits can be confusing. in this post, we’ll explore the intricacies of open loop and closed loop cooling towers to help building managers and industrial operators make informed […].

Open Loop Cooling Tower Schematic In open loop and closed loop cooling towers, the fill media facilitates the contact between air and the water surface. this media helps the water spread into thin, flowing layers, maximizing the surface area exposed to the air flow. fill media is typically made from materials such as polypropylene, wood, or pvc. Cooling towers play a critical role in maintaining the temperature of industrial and commercial operations. but understanding the different types of cooling towers, their functions, and their benefits can be confusing. in this post, we’ll explore the intricacies of open loop and closed loop cooling towers to help building managers and industrial operators make informed […]. Whether open or closed loop heat rejection equipment is specified, be certain to select equipment that is cti (cooling tower institute) certified. open loop equipment. the most prevalent type of large scale heat rejection equipment in use today is the open loop cooling tower. 2. indirect cooling – closed loop. indirect closed loop cooling towers are similar to direct cooling open loop systems. in an indirect closed loop cooling tower, the water that is being cooled never comes into direct contact with the surrounding air. instead, the water flows through a coil in a closed loop system.

Comments are closed.