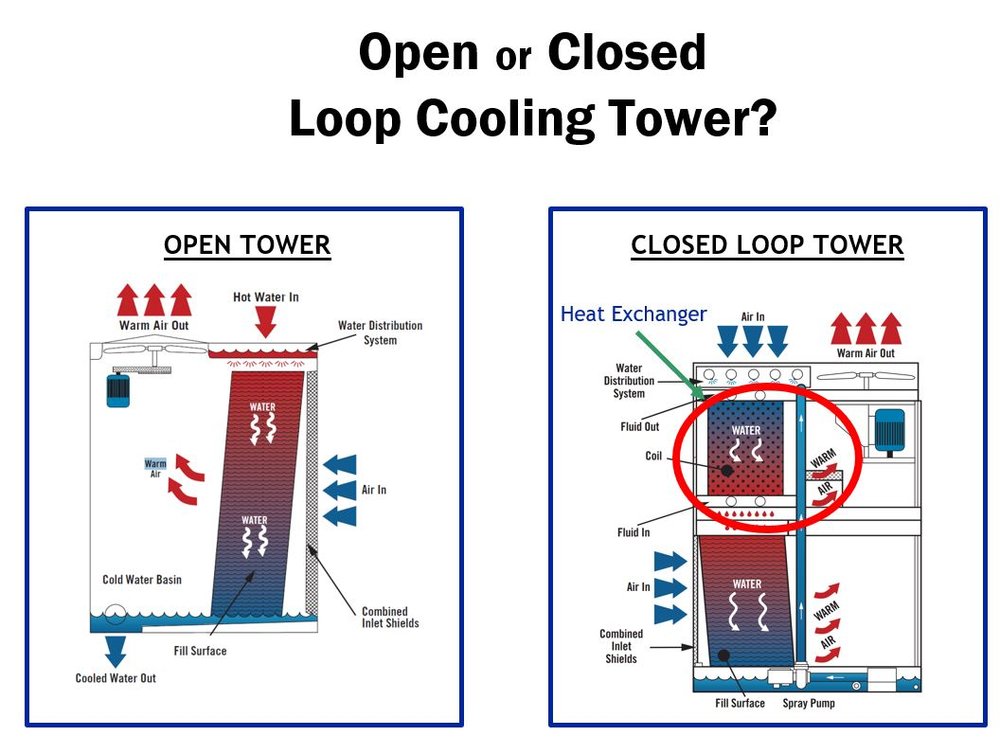

Open Loop And Closed Loop Cooling Tower

How To Pick A Cooling Tower Comparing Open And Closed Loop Towersођ Different types of closed circuit cooling tower systems. another closed circuit cooling tower system involves a separate heat exchanger package along with an open cooling tower. the fluid on the hot side of the heat exchanger also never makes direct contact with the air. this allows the heat exchanger to be put inside, protected from the. Closed circuit cooling towers operate similarly to open towers except there is a heat exchanger coil within the tower that separates the cooling tower water from the building cooling water. during operation cooling tower water is pumped from the basin up to a spray header where it is then sprayed onto a coil containing the building cooling water, thereby cooling it down.

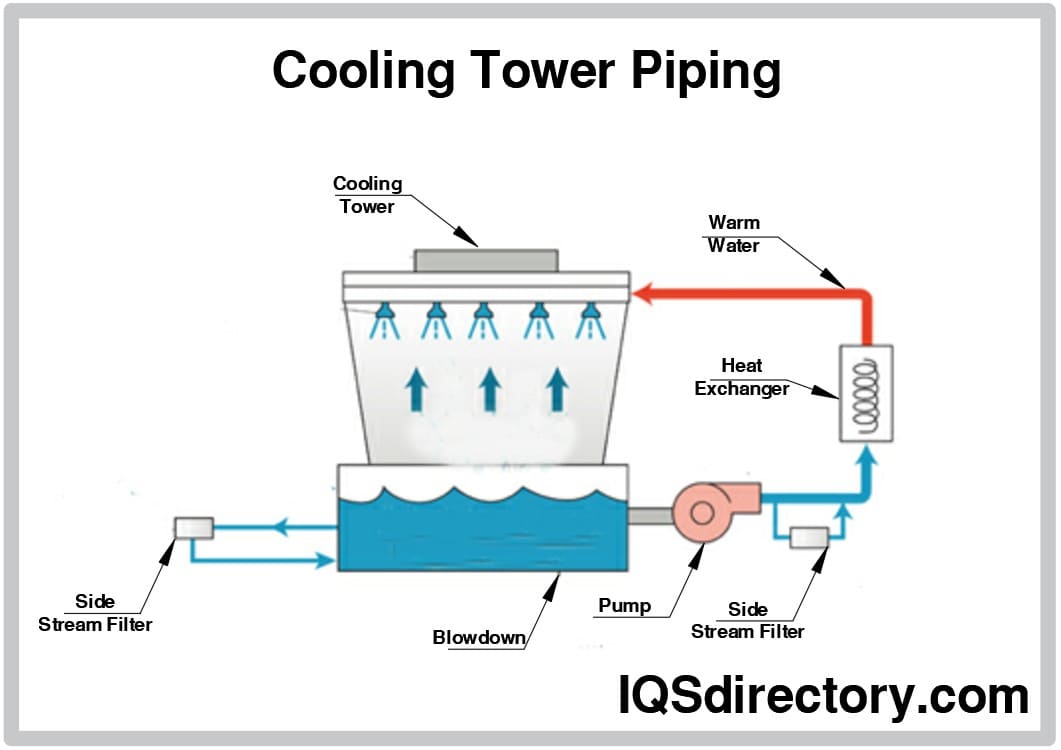

Open Loop Closed Loop Cooling Towers Uses Benefits Closed loop vs open loop operation. in a closed circuit cooling tower, the process fluid, which could be water, or a water glycol mixture is circulated within a closed loop piping system. there are two separate water sources, one external within a closed loop, and the second one that circulates water from the tower basin over the heat exchanger. Evapco’s wide range of closed circuit coolers, or simply “fluid coolers” provide a heat rejection alternative for engineers or end users who want (or need) to reduce water consumption and equipment maintenance, or a number of other considerations that exist with open loop cooling applications. some cooling applications require a closed. In open loop and closed loop cooling towers, the fill media facilitates the contact between air and the water surface. this media helps the water spread into thin, flowing layers, maximizing the surface area exposed to the air flow. fill media is typically made from materials such as polypropylene, wood, or pvc. Closed circuit cooling towers, also known as evaporative fluid coolers, keep the system clean and contaminant free in a closed loop. this creates two separate fluid circuits: (1) an external circuit, in which spray water circulates over the coil and mixes with the outside air, and (2) an internal circuit, in which the process fluid to be cooled.

Comments are closed.