Mig Welding Whats Happening At The Arc

Mig Welding What S Happening At The Arc Youtube There's a lot going on with the arc in gas metal arc welding, let's break it down. in gas metal arc welding (gmaw), there are several variations of modes tha. Arc welding creates an electric arc to melt two metals and join them together. mig welding uses an automatic wire feed which melts an electrode and adds a filler metal to weld two pieces together. both methods work very well and both create an arc to shield the weld. the difference is in how the arc is made, and so how the weld is formed.

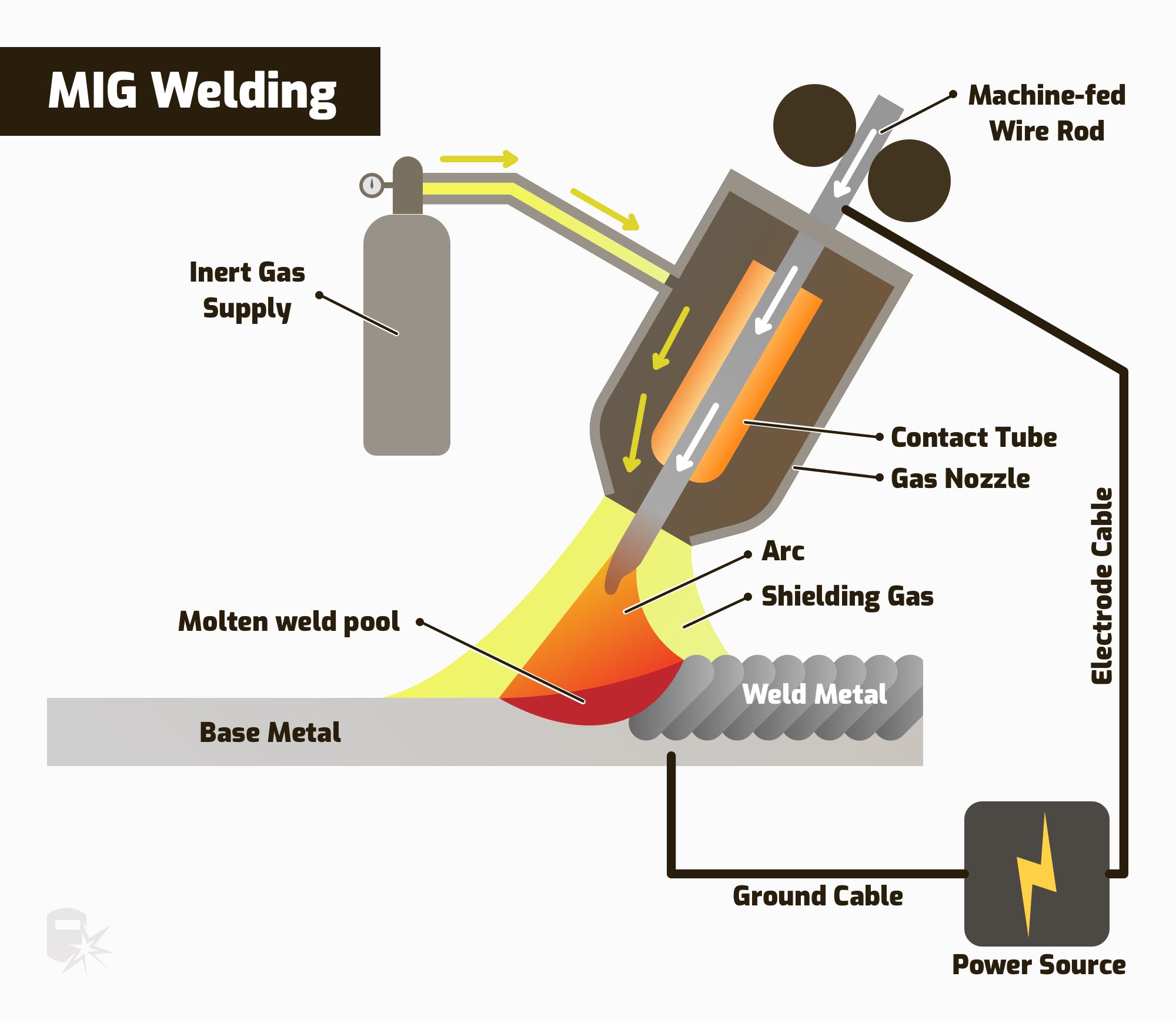

Common Arc Welding Processes At Lisa Bender Blog Fortunately, there are many common reasons why your mig welder might be sputtering, and they are all simple fixes. the top four reasons your mig welder might be sputtering are excessive resistance poor conductivity, dirty wires or welder components, low gas flow, and worn contact tips and liners. when troubleshooting your sputtering mig welder. The following basic mig welding settings are for welding steel with solid wire. joint design, position and other factors affect results and settings. when good results are achieved, record the parameters. material thickness determines amperage. as a guideline, each .001 inch of material thickness requires 1 amp of output: .125 inch = 125 amps. The difference between these three welding techniques is arc usage. tig stands for tungsten inert gas and mig stands for metal inert gas, while arc describes the distinct process that welders use to join metals together. currently, there are over 30 different kinds of welding methods, and some are a lot easier than others. Process characteristics. mig mag welding is a versatile technique suitable for both thin sheet and thick section components. an arc is struck between the end of a wire electrode and the workpiece, melting both of them to form a weld pool. the wire serves as both heat source (via the arc at the wire tip) and filler metal for the welding joint.

Comments are closed.