Metals Free Full Text Effect Of Severe Plastic Deformation On The

Metals Free Full Text Ultrafine Grained Stainless Steels After Aluminium rods with different copper sheath thicknesses were processed by severe plastic deformation at room temperature and then annealed, to join the constituent metals and produce a nanocrystalline microstructure. a study of the effects of the deformation parameters, copper cladding thickness and annealing temperature on the electrical conductivity and hardness of the conductors is reported. In this study, a composite with alternate layers of 5056 and 1580 alloys was manufactured with wire arc additive manufacturing technology. it is shown that increased strength characteristics of composite material can be obtained with deformation treatment using a high pressure torsion (hpt) technique. the microstructure and mechanical properties of the hpt processed material in different.

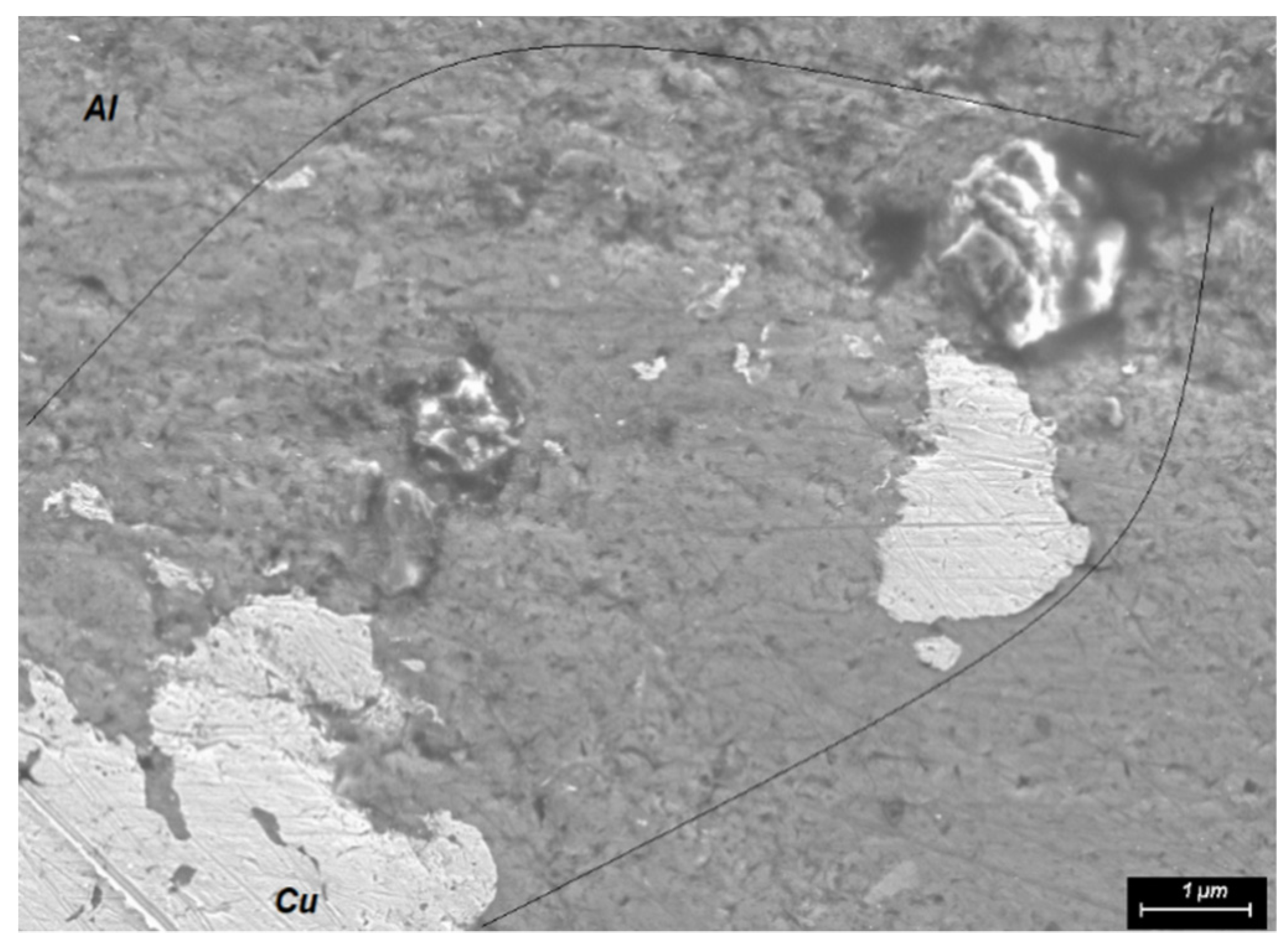

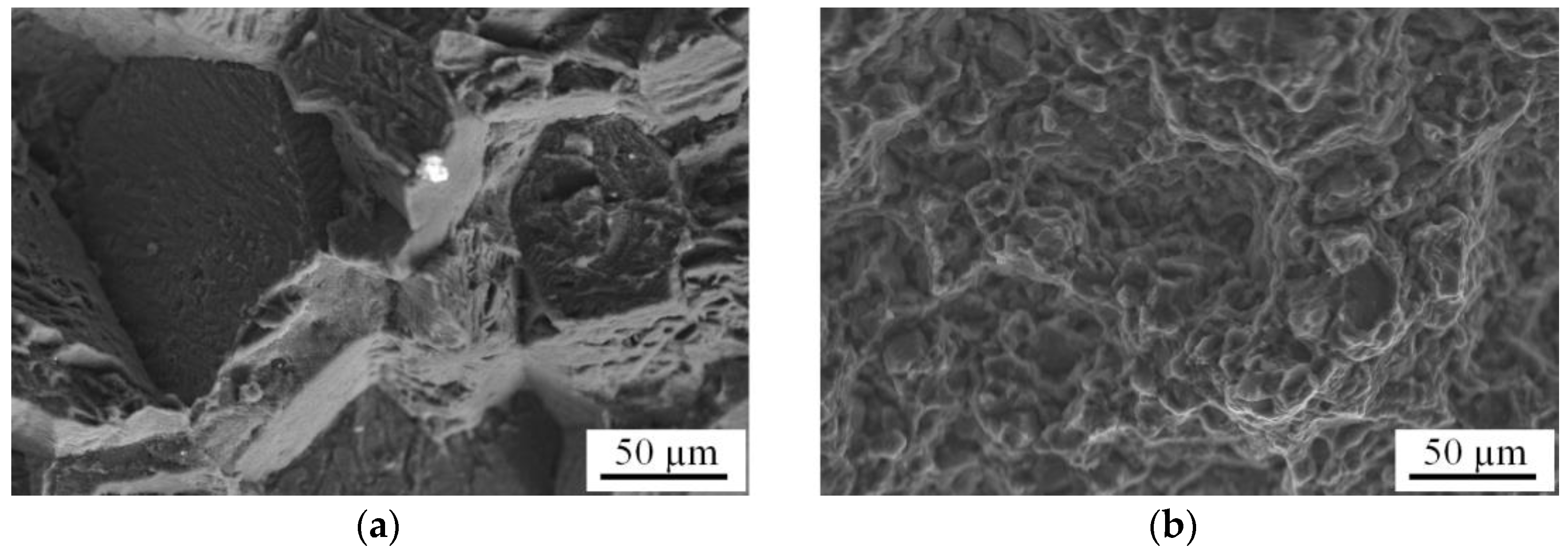

Metals Free Full Text Effect Of Severe Plastic Deformation On The In this study, two innovative surface severe plastic deformation (sspd) methods, namely abrasive waterjet peening (awjp) and ultrasonic nanocrystal surface modification (unsm), were applied to a 304 stainless steel to improve the mechanical behavior. the surface roughness, microstructure, residual stress, hardness, and tensile mechanical properties of the alloy after the two sspd treatments. To investigate the effect of severe plastic deformation on the properties of metal based nanocomposites, consider copper alumina nanocomposite (cu 0.5 wt% al 2 o 3) which has been severely deformed with the high pressure twisting method. Significant deformation of the metal structure can be achieved without breaking or cracking the metal. there are several methods for deformation of metal plastics. the most important of these methods are angular channel pressing process, high pressure torsion, multidirectional forging process, extrusion cyclic compression process, cumulative climbing connection process, consecutive concreting. This paper overviews severe plastic deformation induced structural and mechanical property evolutions on bulk nanocrystalline metals, mainly in a nanocrystalline ni 20%fe (mass fraction) alloy.

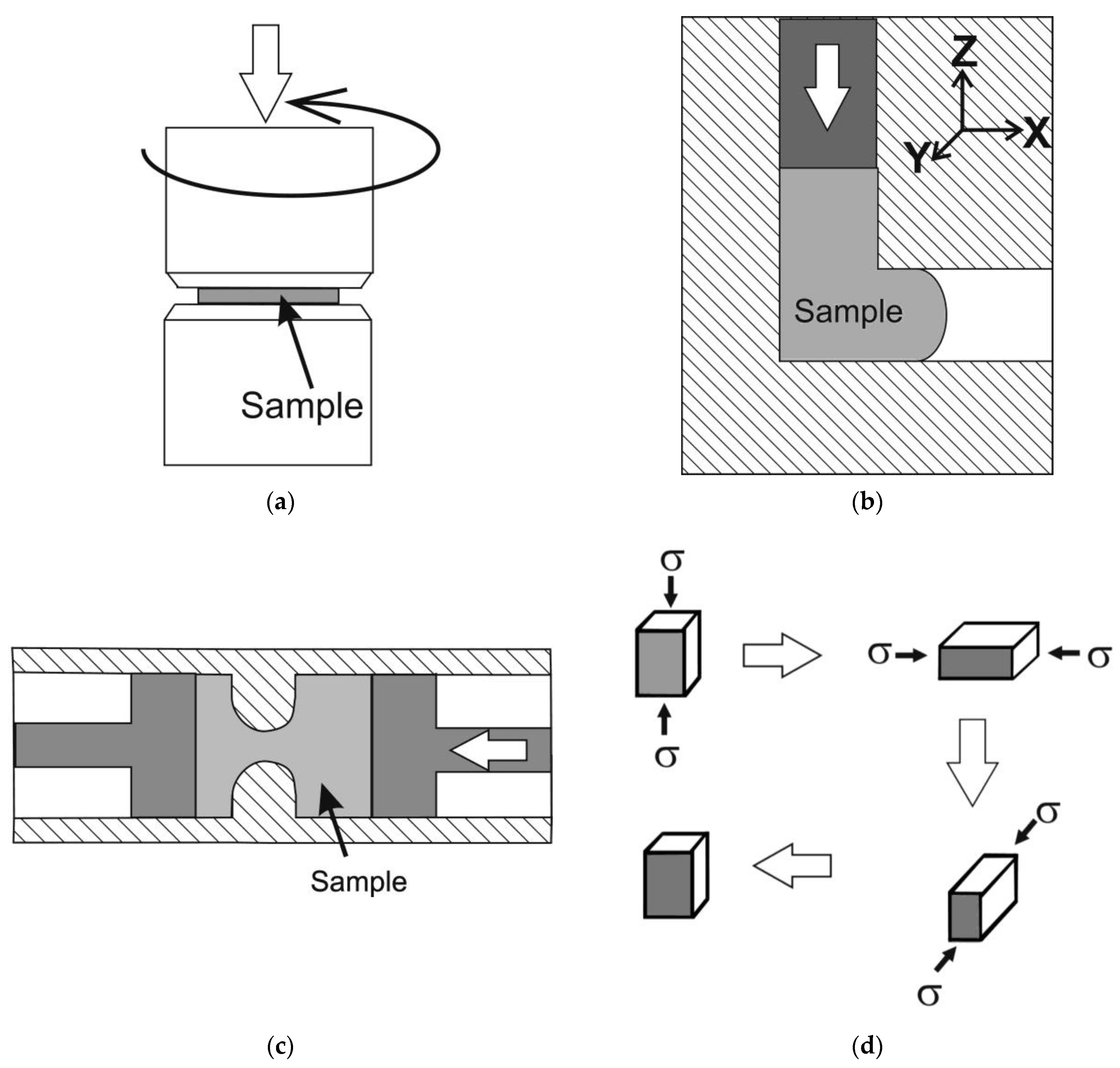

Metals Free Full Text Effect Of Severe Plastic Deformation On The Significant deformation of the metal structure can be achieved without breaking or cracking the metal. there are several methods for deformation of metal plastics. the most important of these methods are angular channel pressing process, high pressure torsion, multidirectional forging process, extrusion cyclic compression process, cumulative climbing connection process, consecutive concreting. This paper overviews severe plastic deformation induced structural and mechanical property evolutions on bulk nanocrystalline metals, mainly in a nanocrystalline ni 20%fe (mass fraction) alloy. Severe plastic deformation technique can be defined as the metal forming process in which a large strain is introduced into a bulk material with the objective to create ultra fine grained (ufg. Figure 1: principles of severe plastic deformation techniques. a, high pressure torsion: a sample is held between anvils and strained in torsion under applied pressure (p). b, equal channel.

Metals Free Full Text Influence Of Severe Plastic Defor Severe plastic deformation technique can be defined as the metal forming process in which a large strain is introduced into a bulk material with the objective to create ultra fine grained (ufg. Figure 1: principles of severe plastic deformation techniques. a, high pressure torsion: a sample is held between anvils and strained in torsion under applied pressure (p). b, equal channel.

Comments are closed.