Mes Solution Erp Integration Mes Software

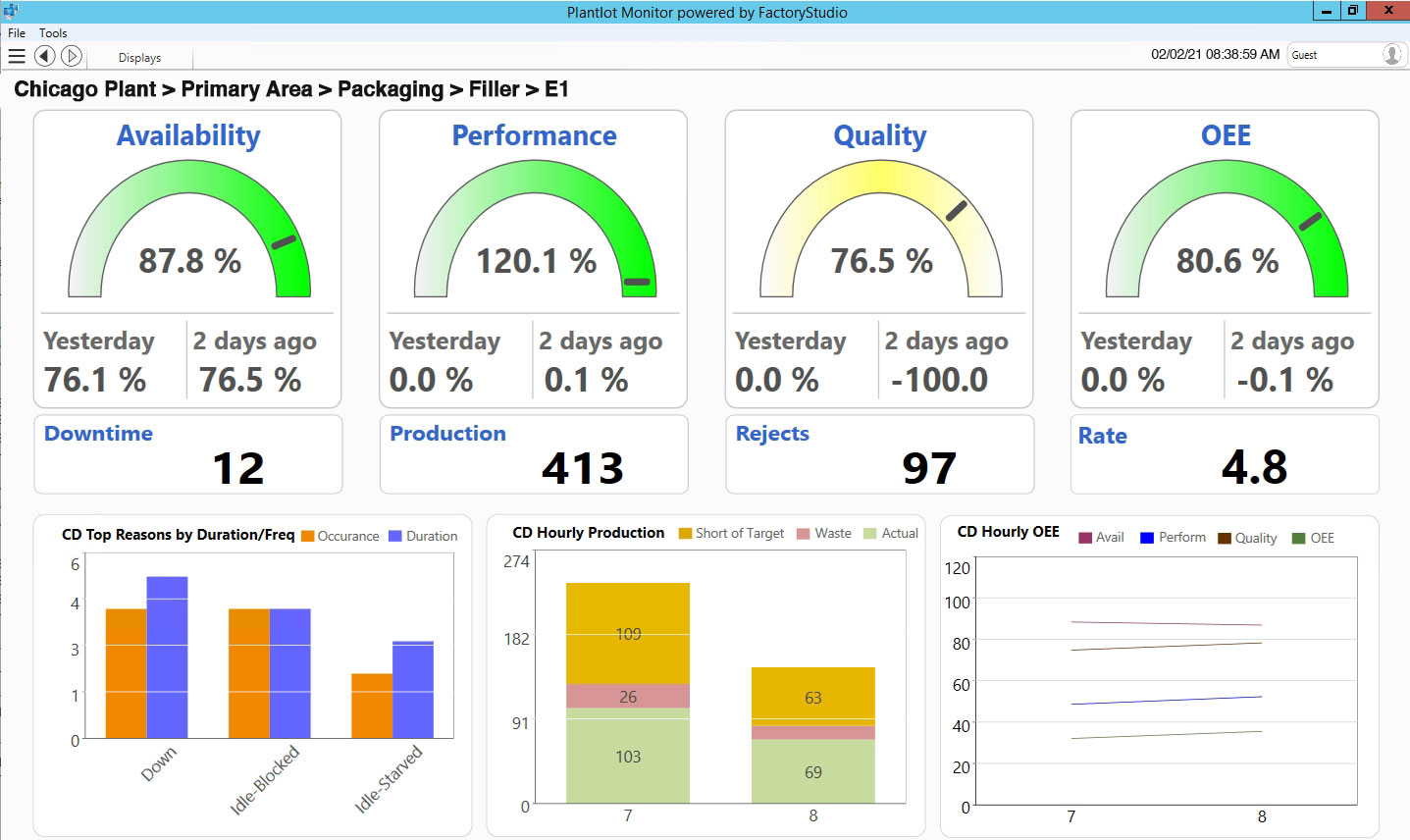

Mes Solution Erp Integration Mes Software Mes erp integration is at the heart of this transformation, acting as the catalyst for a streamlined, digital shop floor. mes erp integration: the digital backbone of paperless operations. while the goal is clear, achieving true paperless manufacturing requires robust technological support. this is where mes erp integration shines:. Integration makes it possible for erp and mes systems to share real time data, which enables real time data synchronization. integration of erp software and mes brings varied business processes into harmony and ensures that data can flow without interruption from the order stage to the production line.

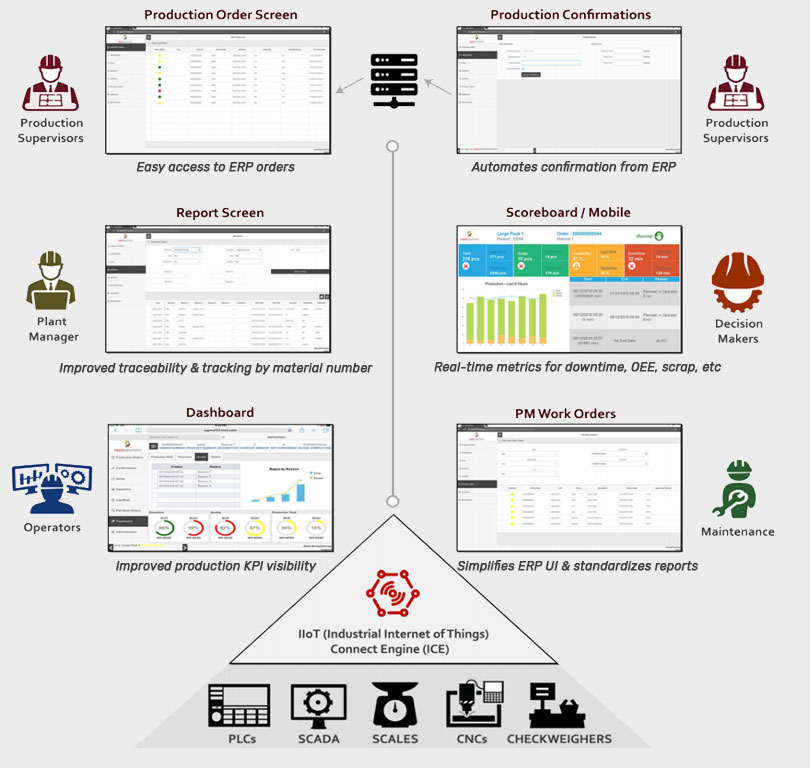

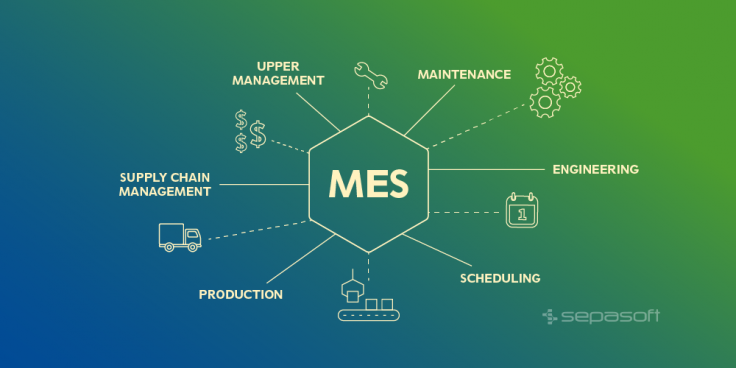

14 Steps For Implementing Mes Sepasoft Mes Solutions Integration capabilities: ensure that the mes solutions can seamlessly integrate with your existing systems, such as erp software, supervisory control and data acquisition (scada) systems, and other relevant manufacturing software. support and training: consider the level of support provided by the vendor during and after implementation. The mes & erp integration defines the connections between two systems that enable seamless data flow. the integration can be implemented via two approaches: industry 3.0 — the development of custom connections between systems. the connections need to be manually updated when new changes in data structure are made. Efficient interaction between manufacturing execution system (mes) and enterprise resource planning (erp) software is critical to a manufacturer’s productivity and on time delivery of products. integration of mes and erp systems enables their complementary functionality to bring greater benefit to a manufacturer than siloed systems. These systems coordinate this execution of work orders with production scheduling and enterprise level systems like erp and product life cycle management (plm). mes applications also provide feedback on process performance, and support component and material level traceability, genealogy and integration with process history, where required.

Mes Solution Erp Integration Mes Software Efficient interaction between manufacturing execution system (mes) and enterprise resource planning (erp) software is critical to a manufacturer’s productivity and on time delivery of products. integration of mes and erp systems enables their complementary functionality to bring greater benefit to a manufacturer than siloed systems. These systems coordinate this execution of work orders with production scheduling and enterprise level systems like erp and product life cycle management (plm). mes applications also provide feedback on process performance, and support component and material level traceability, genealogy and integration with process history, where required. Sap, a leading provider of enterprise software solutions, offers a suite of manufacturing related products, including sap manufacturing execution system (mes). however, it's important to understand the distinction between mes and erp systems to determine whether sap qualifies as an mes system. The mes erp integration holds the key to success in a manufacturing world where efficiency rules. this combination unifies administrative, operational, and production spheres, resulting in a more robust and responsive business operation. in this guide, we’ll deep dive into mes erp integration, discussing its benefits, the integration process.

Comments are closed.