Manufacturing Process Analytics And Optimization Mnj Software

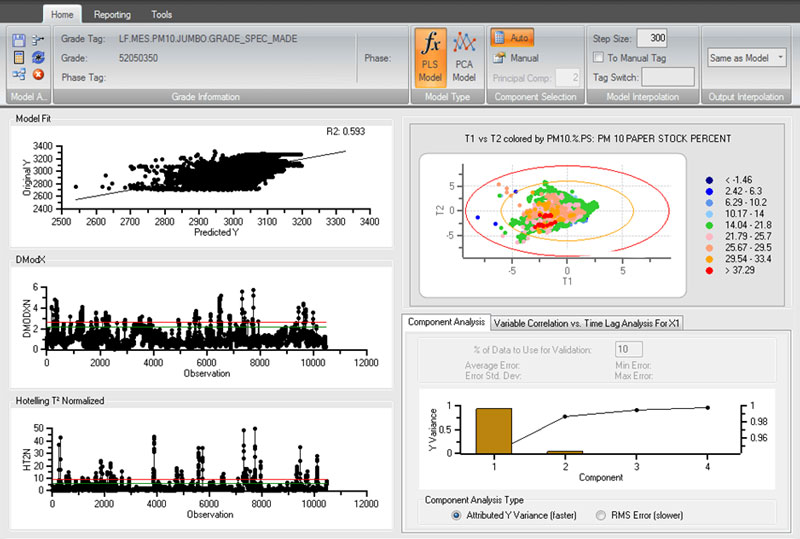

Manufacturing Process Analytics And Optimization Mnj Software Mnj software has developed integrated systems to acquire, manage and analyze process data. these custom solutions for process analytics function as powerful decision support systems, providing summary scorecard views of entire manufacturing processes, while allowing detailed drill down capabilities for each process step and variable. Mnj software’s experience in manufacturing extends beyond software to include deep expertise in process analysis, planning, scheduling and optimization. mnj software currently serves as a strategic partner to recognized global leaders in consumer and industrial manufacturing, working to shorten time to market for some of the most complex new.

Manufacturing Process Optimization Software Mnj helps manufacturers meet the demand for innovative, highly scalable cloud solutions. mnj provides cloud professionals, tools, and services to meet the demand for legacy systems transformation. our teams can help you plan, manage, and execute cloud migrations. services include assisting design, integration, and support of cloud solutions. 7 steps for optimizing manufacturing processes. manufacturing process optimization takes time and careful preparation. but, with the right approach and team of stakeholders, you can soon be optimizing manufacturing processes and set your organization up for long term success. 1. identify improvement areas. Connect, collect, and combine data from any source at the plant. use dataparc’s industry leading data visualization tools to quickly analyze large sets of production data and identify opportunities to improve process efficiency. connect & integrate it & ot data from across the plant. identify the root cause of downtime events or quality issues. Production optimization uses models, analysis, prioritization, and measurements to increase productivity. this optimization includes equipment, staging areas, inventory protocols, facility layout, conveyance, and more. optimizing production is a tactic used in large footprint industries such as oil production and gas construction.

Comments are closed.