Infographic 5 Key Principles Of Lean Manufacturing Vrogue Co

.png/02b4a3d0-5ec9-b311-1b75-69c208373a62)

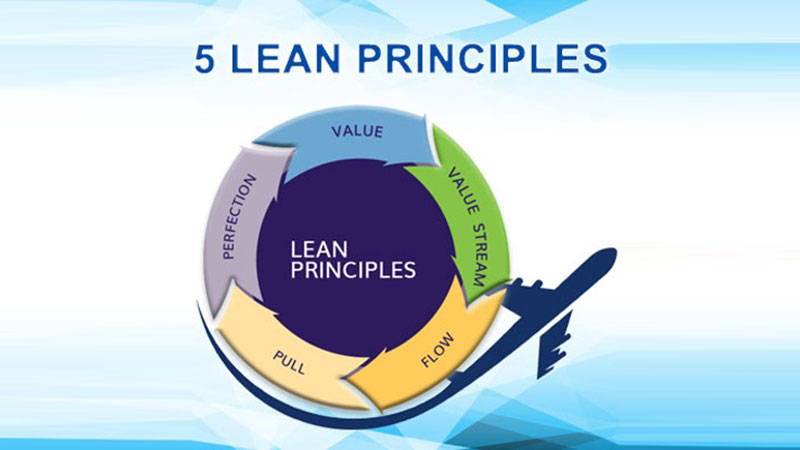

Infographic 5 Key Principles Of Lean Manufacturing Vrogue Co This infographic illustrates the five key principles of lean manufacturing, also known as “lean thinking”. the concepts are broken down as follows: 1) utilize the voice of the customer (voc) tool to specify what is important to your customer. use either direct contact or indirect contact with those customers. direct contact: interviews. Regardless of the industry, if you manufacture any products at all, these five key principles of lean manufacturing are what you need to follow as though your life depended on it. remember, you are manufacturing the product for your customer and they will spend their hard earned money to buy the product that you make.

Infographic 5 Key Principles Of Lean Manufacturing Vrogue Co The five principles of lean manufacturing – value, value stream, flow, pull, and perfection – provide a powerful framework for improving efficiency, reducing waste, and delivering superior value to customers. while each principle is important in its own right, they are most effective when implemented together as an integrated system. The five principles are considered a recipe for improving workplace efficiency and include: 1) defining value, 2) mapping the value stream, 3) creating flow, 4) using a pull system, and 5) pursuing perfection. the next sections provides a detailed overview of each principle. the five lean principles explained: figure 1. the five lean principles. Principle 5: perfection. the lean methodology isn’t a quick fix; it’s a commitment to continuous improvement. empower your team to identify opportunities for improvement, experiment, and learn from both successes and failures. remember, perfection is a mindset, not a finish line. foster a culture of open communication and encourage team. Lean manufacturing principles can also be applied to various business aspects, including inventory optimization and warehouse management. streamlining processes, reducing lead times, and improving quality can deliver value in terms of cost savings, improved customer satisfaction, and increased operational efficiency.

Infographic 5 Key Principles Of Lean Manufacturing Vrogue Co Principle 5: perfection. the lean methodology isn’t a quick fix; it’s a commitment to continuous improvement. empower your team to identify opportunities for improvement, experiment, and learn from both successes and failures. remember, perfection is a mindset, not a finish line. foster a culture of open communication and encourage team. Lean manufacturing principles can also be applied to various business aspects, including inventory optimization and warehouse management. streamlining processes, reducing lead times, and improving quality can deliver value in terms of cost savings, improved customer satisfaction, and increased operational efficiency. 5 fundamental principles in lean . the five pillars of lean manufacturing are fundamental principles that support this management philosophy, guiding organizations in implementing more efficient processes and eliminating waste. they form the foundation for value creation and continuous improvement within lean production. the five pillars are:. Plan: a cross functional team identifies a problem and “plans” a possible solution. do: the team will then “do” the steps required to test this solution. check: the team will “check” whether or not the solution will be successful by analyzing the trial results.

Comments are closed.