How To Repair Wiring Harness

How To Repair A Wiring Harness Partzilla Watch as we repair a wiring harness that had been chewed on by a few mice. the video gives you a basic process on how to prepare, solder and repair damaged w. To test the wiring harness, first remove the wires connected to the accessory. carefully trace the wires back to the first connection point you encounter. this may require the removal of the wires from the protective plastic tubing. disconnect the wires at that first connection point encountered. 9.

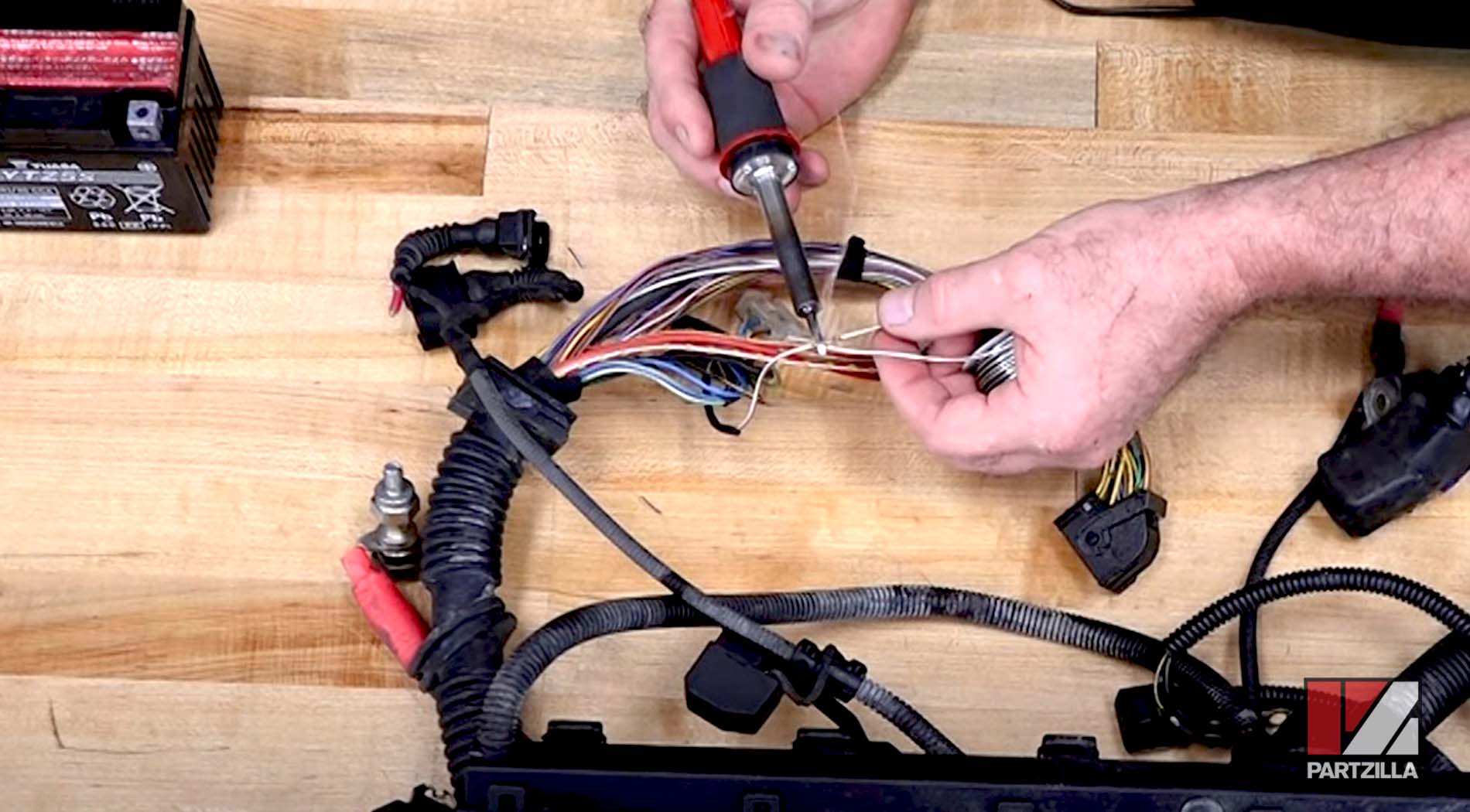

How To Repair A Wiring Harness Partzilla Put the tubing on before you start the connection and solder it on. make sure you get the connection hot enough to where the solder flows into the wire and it’s not just globbed up on the outside. let the tubing cool down a bit before you bring in the heat shrink gun. when you heat shrink it, put the connection roughly in the middle. On project cars, restoring, retapping, repairing or fixing damaged wiring harness is a common repair. if you have damaged wiring you always want to fix it wh. We'll show how to correctly repair automobile wiring, we'll also teach you how to properly seal and protect your wire harness from the elements preventing wi. How to fix wiring harnesses. step 1: access the damaged section. step 2: confirm the wire harness connectors and wire gauge are the same. step 3: strip the wire ends. step 4: connect the wire ends. step 5: melt the insulation. step 6: wrap the wires. step 7: testing. things to keep in mind when fixing wiring harnesses.

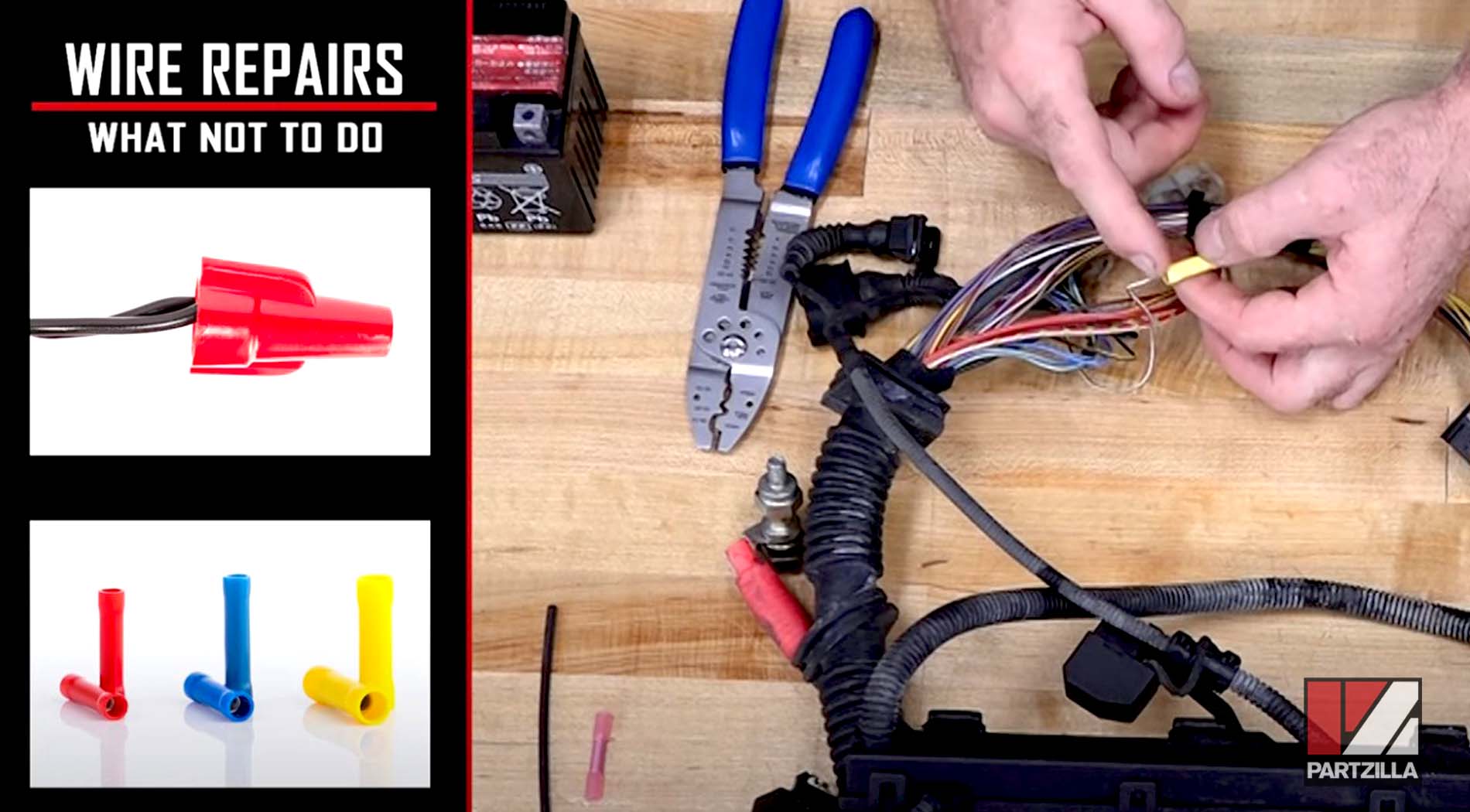

How To Repair A Wiring Harness Partzilla We'll show how to correctly repair automobile wiring, we'll also teach you how to properly seal and protect your wire harness from the elements preventing wi. How to fix wiring harnesses. step 1: access the damaged section. step 2: confirm the wire harness connectors and wire gauge are the same. step 3: strip the wire ends. step 4: connect the wire ends. step 5: melt the insulation. step 6: wrap the wires. step 7: testing. things to keep in mind when fixing wiring harnesses. Automobile harness repair is a necessary skill for every automobile technician. wiring harnesses can become damaged over time due to wear and tear, environmental exposure, or accidents, resulting in electrical problems with a vehicle. understanding how to efficiently repair these harnesses can save time and money by avoiding costly replacements. Strip about a 1 4 inch of insulation from the wire, then slip the terminal over the exposed wire. you don’t want much wire hanging out the end of the terminal. about a 1 16 inch is perfect. this means there is wire through the entire crimp zone and it won’t slip out during crimping.

Comments are closed.