How Maintenance Planning Scheduling Works

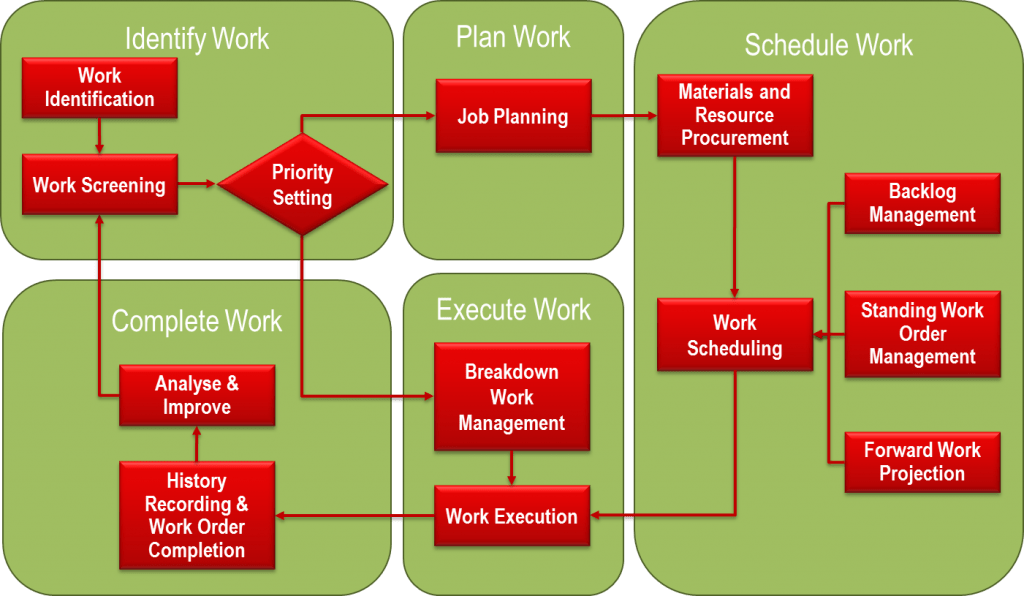

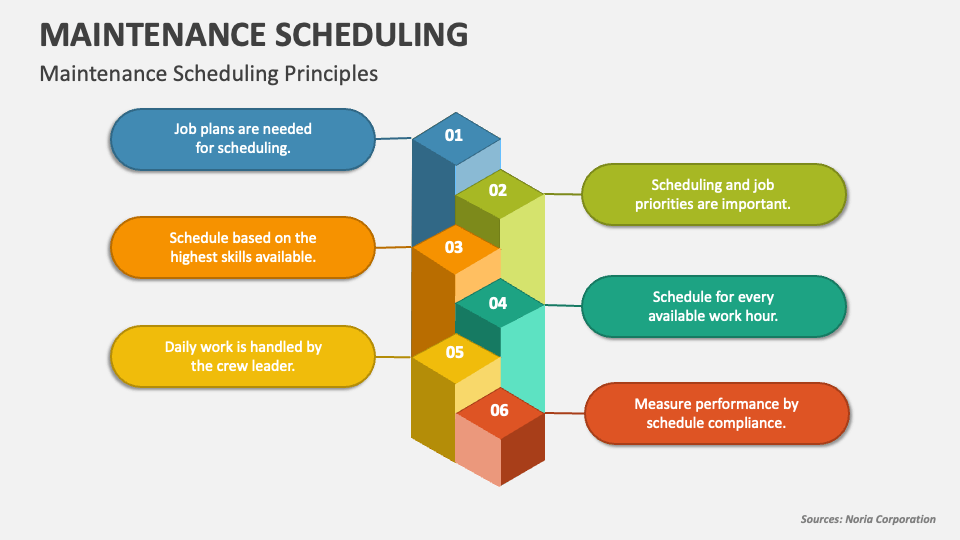

5 Tips For Effective Maintenance Planning And Scheduling Assetivity Maintenance scheduling refers to the timing of planned work, when the work should be done and who should perform it. it offers details of "when" and "who." scheduling is meant to: schedule the maximum amount of work with the available resources. schedule according to the highest priority work orders. The maintenance planner, supervisor, manager or team lead will generally take this step on. do: follow your plan consistently for accurate results. the maintenance technician will be responsible for this step. check: look at failure metrics for each asset to determine if your plan is working.

Maintenance Planning And Scheduling An Overview Maintenance scheduling refers to setting specific timeframes or intervals for performing planned maintenance tasks. it involves determining when each task should be executed based on factors like asset criticality, historical performance data, manufacturer recommendations, and operational requirements. the scheduling process ensures that. Maintenance scheduling is the process in which the maintenance department plans, organizes, and coordinates all maintenance activities that need to be completed to ensure equipment is working in optimal condition. as per maintenance experts, the primary reasons behind unscheduled equipment downtime include aging equipment (34%), mechanical. Plan for future work – job planners should be solely focused on the work that’s ahead of the maintenance team, rather than the tasks they’re currently completing. this means building a work backlog that extends a minimum of one week into the future, so all jobs are completely planned and ready to schedule with plenty of advanced notice. Phase 1: setup – the setup phase is crucial for laying the groundwork for successful maintenance planning and scheduling by ensuring leadership support and resource allocation. that you have built a clear case for change. that you identified key stakeholders and put an initial communications plan in place.

Maintenance Scheduling Powerpoint Presentation Slides Ppt Template Plan for future work – job planners should be solely focused on the work that’s ahead of the maintenance team, rather than the tasks they’re currently completing. this means building a work backlog that extends a minimum of one week into the future, so all jobs are completely planned and ready to schedule with plenty of advanced notice. Phase 1: setup – the setup phase is crucial for laying the groundwork for successful maintenance planning and scheduling by ensuring leadership support and resource allocation. that you have built a clear case for change. that you identified key stakeholders and put an initial communications plan in place. Maintenance planning is the systematic process of identifying, scheduling, and organizing maintenance activities to ensure that equipment and assets operate efficiently, safely, and reliably. it involves determining necessary tasks, resources, and schedules ahead of time to minimize downtime, optimize resource utilization, and extend the. 3. determine the frequency of maintenance. schedule inspections and maintenance based on the frequency required for each piece of equipment. there are likely activities that must be performed daily, while others can wait a week, month or can be done whenever required through a work order.

Maintenance Planning And Scheduling An Overview вђ Erudite Reliability Maintenance planning is the systematic process of identifying, scheduling, and organizing maintenance activities to ensure that equipment and assets operate efficiently, safely, and reliably. it involves determining necessary tasks, resources, and schedules ahead of time to minimize downtime, optimize resource utilization, and extend the. 3. determine the frequency of maintenance. schedule inspections and maintenance based on the frequency required for each piece of equipment. there are likely activities that must be performed daily, while others can wait a week, month or can be done whenever required through a work order.

Comments are closed.