Haccp Checklists To Improve Your Food Safety Program Safesite

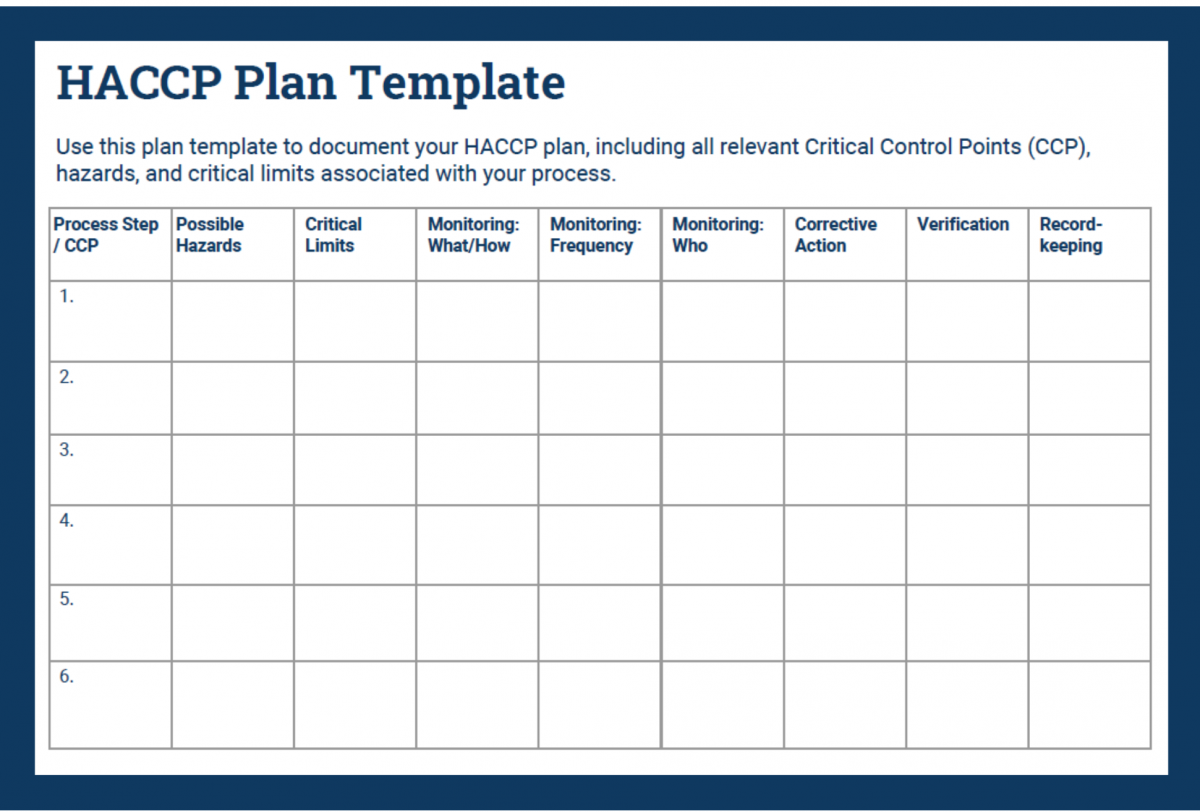

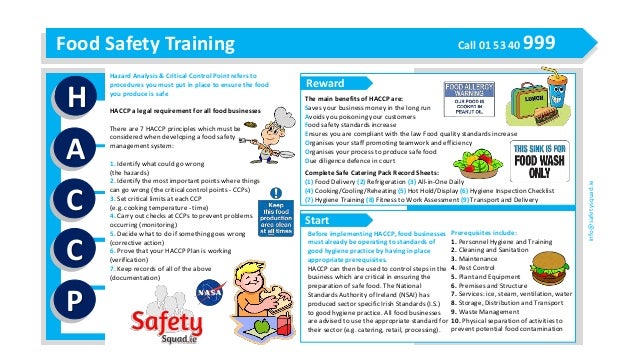

Haccp Checklists To Improve Your Food Safety Program Safesite Whatever your situation, you can streamline your procedures with the use of haccp checklists. during your haccp planning phase, you identified critical control points (ccps) that must be held to critical limits. to monitor food safety (and document monitoring related activities), production staff rely on logs and checklists to maintain consistency. Principle 1: conduct a hazard analysis. you should begin any major process in your food processing business by first conducting a hazard analysis. a hazard analysis involves identifying the most significant hazards as well as where they are most likely to occur in each step of the production process.

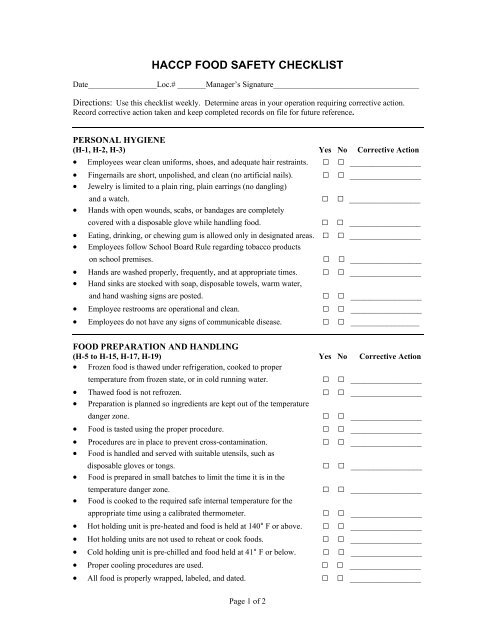

Haccp Food Safety Checklist Completing your haccp plan: a step by step guide. by team safesite. january 18, 2020. the hazard analysis and critical control point (haccp) system provides a systematic, globally recognized approach to reducing safety hazards in food production systems. use a haccp system to control potential biological, physical, and chemical hazards that. By using this checklist, you can identify gaps and make necessary adjustments to optimize your haccp plan and enhance food safety. 6. haccp prerequisite program checklist. the haccp prerequisite program checklist verifies the foundational aspects underpinning a robust haccp plan. it encompasses personal practices, food handling, storage, and. Haccp is a scientific system for process control that has long been used in food production. it prevents food safety problems by applying controls at identified points in a food production process at whichhazards can be prevented, controlled, eliminated, or reduced to acceptable levels. an effective haccp system includes: • a haccp plan ;. In this checklist, you will find the twelve steps to the haccp process, the tasks for each step, and an area to add notes for each. it acts as a systematic approach to identifying potential gaps in your program, something every food safety professional knows is a constant goal. this checklist will allow you to verify that you are considering.

Haccp Checklists To Improve Your Food Safety Program Safesite Haccp Haccp is a scientific system for process control that has long been used in food production. it prevents food safety problems by applying controls at identified points in a food production process at whichhazards can be prevented, controlled, eliminated, or reduced to acceptable levels. an effective haccp system includes: • a haccp plan ;. In this checklist, you will find the twelve steps to the haccp process, the tasks for each step, and an area to add notes for each. it acts as a systematic approach to identifying potential gaps in your program, something every food safety professional knows is a constant goal. this checklist will allow you to verify that you are considering. Also known as the hazard analysis and critical control points plan, it is a food safety monitoring system that helps identify and control biological, chemical, and physical hazards within the storage, transportation, use, preparation, and sale of perishable goods. it also determines critical control points (ccp) in the process of food production. Contributor: safesite jurisdiction: osha food services and production to maintain food safety measures, use this haccp hazard analysis in every step of your food production and handling process to determine if any physical, chemical or biological threats are present.

Haccp Food Safety Storage Also known as the hazard analysis and critical control points plan, it is a food safety monitoring system that helps identify and control biological, chemical, and physical hazards within the storage, transportation, use, preparation, and sale of perishable goods. it also determines critical control points (ccp) in the process of food production. Contributor: safesite jurisdiction: osha food services and production to maintain food safety measures, use this haccp hazard analysis in every step of your food production and handling process to determine if any physical, chemical or biological threats are present.

Comments are closed.