Guide To Lean Six Sigma In Manufacturing To Improve Production

Guide To Lean Six Sigma In Manufacturing To Improve Production Radiant The “5s methodology” – where 5s stands for sort, set in order, shine, standardize, and sustain – involves practices to create a clean and organized workplace, promoting continuous improvement and maximizing efficiency. six sigma tools play a crucial role in improving manufacturing processes. the “dmaic methodology” (define, measure. Six sigma: the quest for quality. six sigma offers a more data driven approach. it was developed by motorola in the 1980s as a way to systematically improve the quality of their products. the core of six sigma lies in understanding and reducing variability in processes, which can lead to defects. key elements include:.

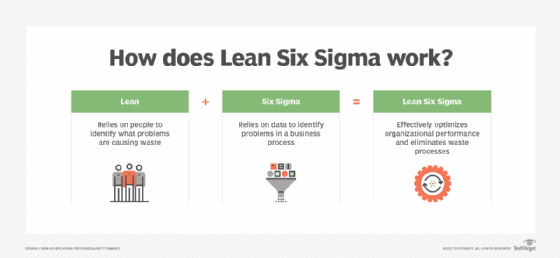

Lean Six Sigma Process Improvement Goleansixsigma Glss Lean The lean six sigma methodology. as previously mentioned, lean six sigma is a structured and systematic approach that combines lean and six sigma principles to achieve operational excellence and continuous improvement in organizations. it provides a clear and directed path for problem solving and process improvement, addressing waste elimination. Lean six sigma is a systematic approach to reduce or eliminate activities that do not add value to the process. it highlights removing wasteful steps in a process and taking the only value added steps. the lean six sigma method ensures high quality and customer satisfaction in the manufacturing. the main purpose of this chapter is to explore the lean six sigma (lss) in the manufacturing sector. A sigma of 5.3 is very good, but there is still a space of 0.7 for improvement to reach our six sigma goal. analyze: understand where the problems in your process lie the analysis step is where we have to dig in deep into the existing processes and work out the root causes of the problems. What is six sigma? “six sigma” is a term that comes from a mathematical idea used in manufacturing. when a production process is six sigma also known as 6 standard deviations away from the specification limits where problems and defects are produced, it means it is a very capable process and only produces up 3.4 defects out of a million opportunities.

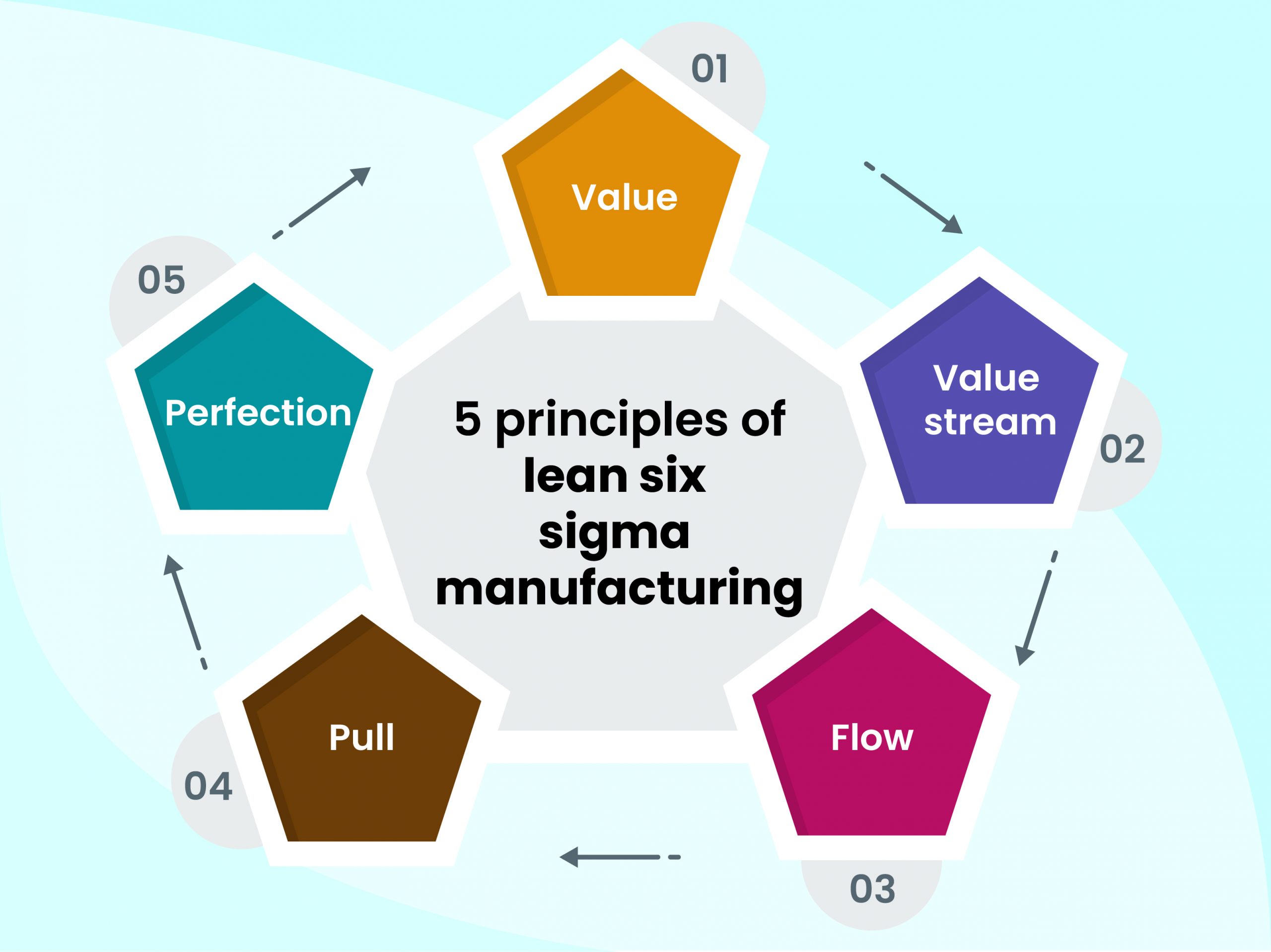

What Is Lean Six Sigma How Is It Different From Six Sigma A sigma of 5.3 is very good, but there is still a space of 0.7 for improvement to reach our six sigma goal. analyze: understand where the problems in your process lie the analysis step is where we have to dig in deep into the existing processes and work out the root causes of the problems. What is six sigma? “six sigma” is a term that comes from a mathematical idea used in manufacturing. when a production process is six sigma also known as 6 standard deviations away from the specification limits where problems and defects are produced, it means it is a very capable process and only produces up 3.4 defects out of a million opportunities. The five phases of lean six sigma. the lean six sigma methodology consists of five phases, commonly known as dmaic: define, measure, analyze, improve, and control. define: in this initial phase, the project goals and scope are defined. organizations must clearly understand the problem they are trying to solve and the desired outcome. As defined by jones and womack, effective lean management promotes a never ending cycle of improvement and waste removal designed to: increase production. decrease downtime. improve products and services. eliminate process and product defects. streamline inventory. make the best use of your workforce’s skills.

7 Lean Six Sigma Methodology Can Speed Up Your Business Growth The five phases of lean six sigma. the lean six sigma methodology consists of five phases, commonly known as dmaic: define, measure, analyze, improve, and control. define: in this initial phase, the project goals and scope are defined. organizations must clearly understand the problem they are trying to solve and the desired outcome. As defined by jones and womack, effective lean management promotes a never ending cycle of improvement and waste removal designed to: increase production. decrease downtime. improve products and services. eliminate process and product defects. streamline inventory. make the best use of your workforce’s skills.

Comments are closed.