Gmaw Basics How To Improve Your Mig Welds With 5 Simple Steps

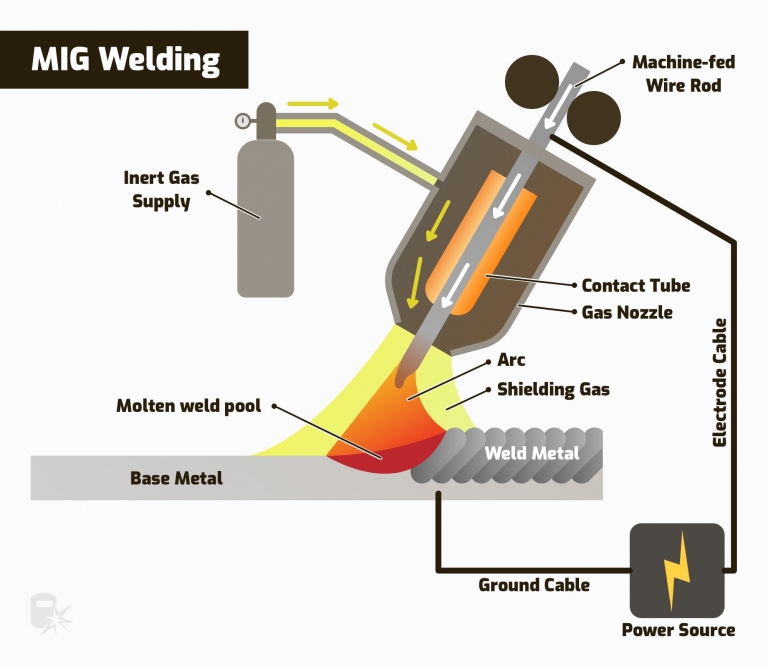

Gmaw Basics How To Improve Your Mig Welds With 5 Simple Steps Hello and thanks for tuning in to fabrication 101.gmaw or mig welding as it is commonly known is probably one of the most commonly used welding processes in. Mig welding requires shielding the weld from the atmosphere. to do this, direct shielding gas over the weld area, and control the flow of gas by the trigger on the gun. in other instances, welders might use a flux cored wire, either alone or with a gas shield. the majority of mig welding requries a gas shield — carbon dioxide and argon co2.

What Is Gmaw Mig Welding How Does It Work Weld Guru This article will give you 16 great tips to get you on the quickest path to success. table of contents show. 1. make sure your metal is clean. like every welding process you’ll use in your welding journey, step one should always be to make sure your material is nice and clean. Gmaw weld parameters. the following tips can help you prepare for the next gmaw job. 1. select the correct shielding gas to get the best result from your filler metal. solid wire electrodes used in gmaw require a shielding gas to protect the molten weld puddle from impurities in the atmosphere, specifically oxygen and nitrogen. Set your machine to a lower voltage and wire feed speed than for flat or horizontal welding. this will prevent the weld puddle from sagging or dripping down. hold the gun at a slight upward angle (5 to 15 degrees) and push the weld pool uphill. this will give you better visibility and gas coverage. One of the best mig welding tips is to reduce the voltage and amperage by around 10 15% when compared to your flat welding settings. vertical down welding is used to reduce arc penetration when working on thin metals. this, in turn, stops excessive melt through. worker doing a vertical position weld.

How To Mig Weld Gmaw Setup And Troubleshooting Gmaw Weld Metal Set your machine to a lower voltage and wire feed speed than for flat or horizontal welding. this will prevent the weld puddle from sagging or dripping down. hold the gun at a slight upward angle (5 to 15 degrees) and push the weld pool uphill. this will give you better visibility and gas coverage. One of the best mig welding tips is to reduce the voltage and amperage by around 10 15% when compared to your flat welding settings. vertical down welding is used to reduce arc penetration when working on thin metals. this, in turn, stops excessive melt through. worker doing a vertical position weld. 3. stainless steel. stainless steel is a corrosion resistant metal that requires a specific wire and shielding gas for mig welding. you should use a tri mix shielding gas that contains argon, helium, and carbon dioxide. it is also important to clean the metal surface before welding to ensure a strong weld. Horizontal position mig welding techniques. horizontal welding is a little harder. the mig gun should be pointing upward between 35 to 45 degrees and tilting about 15 to 35 degrees toward the direction of the weld. you need to watch out for overlap and the weld rolling over. always keep it to a tight stringer beads on any joint.

Industrial Applications Of Mig Welder Gmaw Basic Technique Of Mig 3. stainless steel. stainless steel is a corrosion resistant metal that requires a specific wire and shielding gas for mig welding. you should use a tri mix shielding gas that contains argon, helium, and carbon dioxide. it is also important to clean the metal surface before welding to ensure a strong weld. Horizontal position mig welding techniques. horizontal welding is a little harder. the mig gun should be pointing upward between 35 to 45 degrees and tilting about 15 to 35 degrees toward the direction of the weld. you need to watch out for overlap and the weld rolling over. always keep it to a tight stringer beads on any joint.

Comments are closed.