Flow Diagram Of Cooling Tower

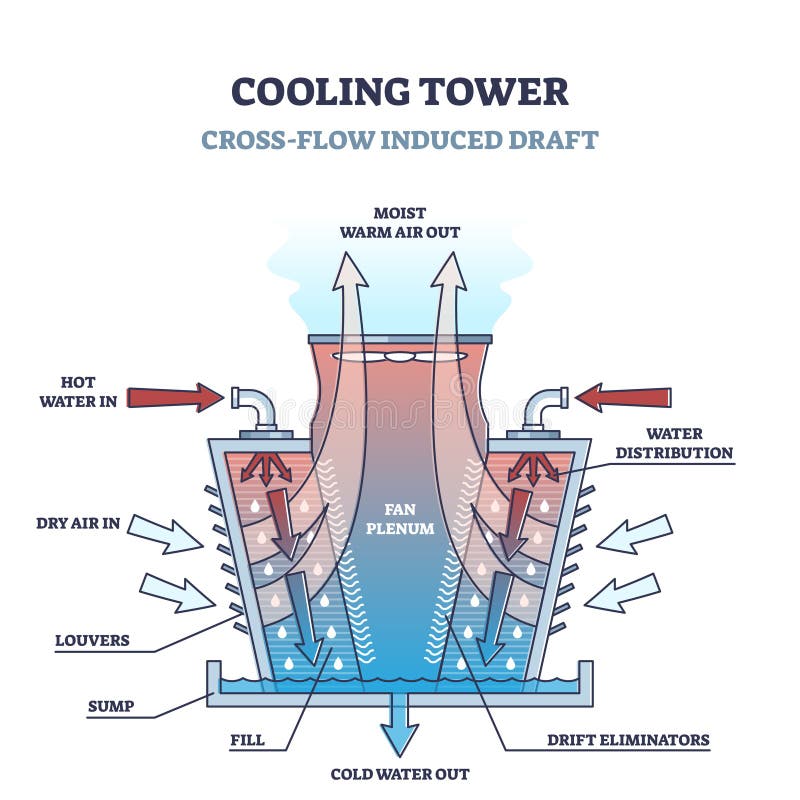

Cross Flow Cooling Tower Type Structure And Work Principle Outline A cooling tower flow diagram is an essential tool for understanding the operation and efficiency of a cooling tower system. it allows engineers and technicians to identify potential bottlenecks or areas for improvement, ensuring that the tower is functioning optimally and meeting the cooling needs of the industrial process. Cooling tower spouts are managed to diffuse the water over the “fill media,” that reduces the flow of water and reveals the maximum volume of water covering area desirable for the safest air water connection. the water is flashed to air as it passes throughout the cooling tower. the air has been pulled using a motor driven electrical.

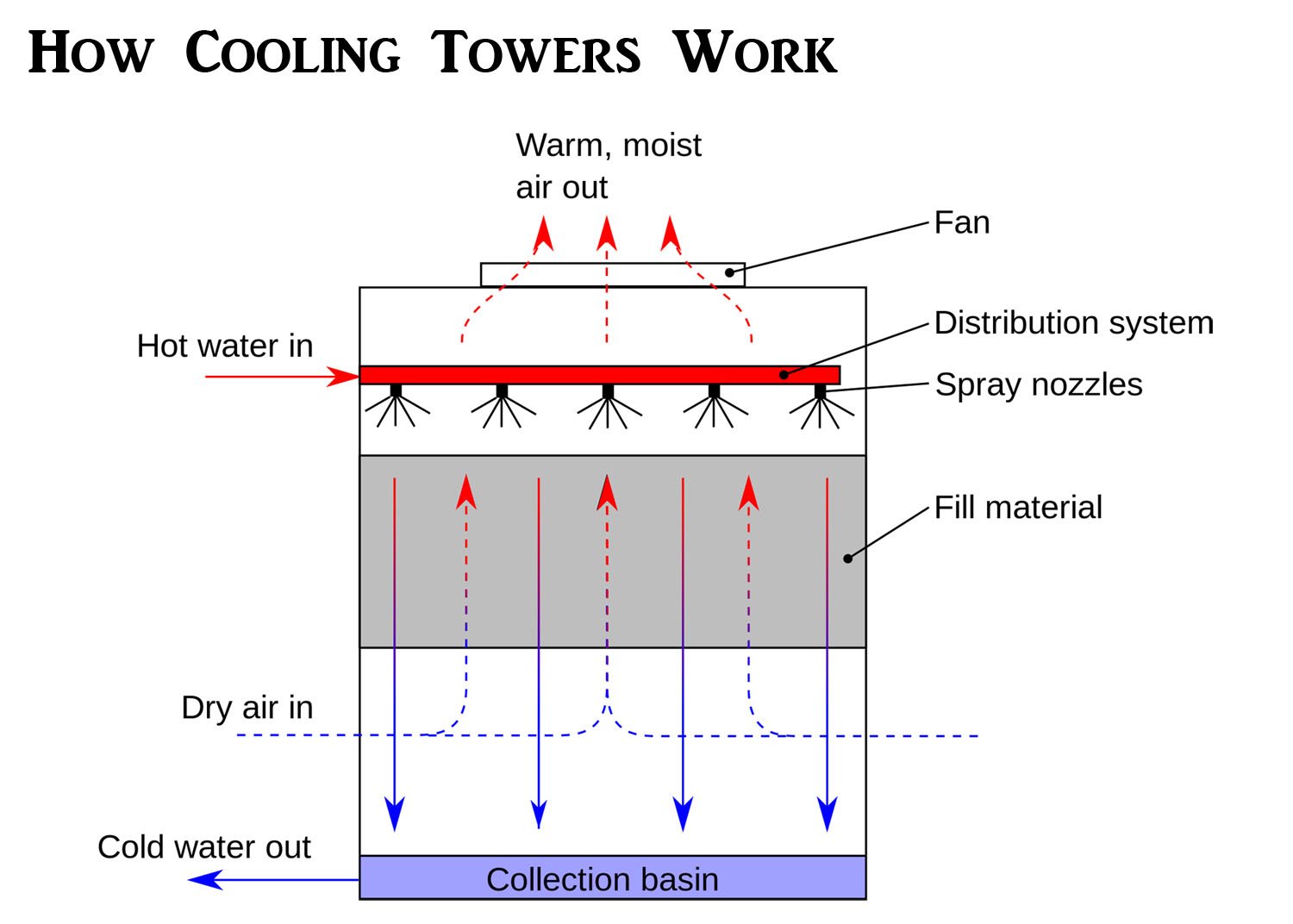

How Cooling Towers Work W Diagram Pictures Principles 2018 Condenser water return pipework [1] the cooling tower return pipework is installed to transport the warm water from the condenser side of the water cooled chiller to the cooling tower, with the flow being provided by the condenser water pumps that are installed on the supply side of the tower [tower to chiller] to move the water around the system. Crossflow cooling towers flow diagram in crossflow cooling tower systems the water vertically flows through the fill media while the air horizontally flows across the falling water. that's why they call it "crossflow" because the air and water cross paths or flows. because of the crossing of flows, the air doesn't need to. Sequence of operation. when the operating fan(s) are operating at 50 percent speed, an additional fan shall be enabled and controlled at the same speed as the operating fans until all active cooling tower cell fans are enabled. when operating fans are running at minimum speed and the tower supply water temperature is five (5) degrees below the. Cooling tower air flowing past fill packaging. combining the spray of water, the thin film of water on the fill packaging and the flow of cool air you get a great amount of heat transfer. flow of air and condenser water. just to recap. warm condenser water enters the tower and is sprayed over the fill packaging.

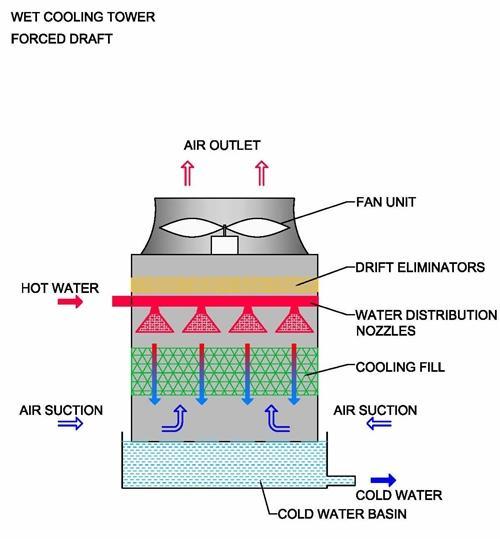

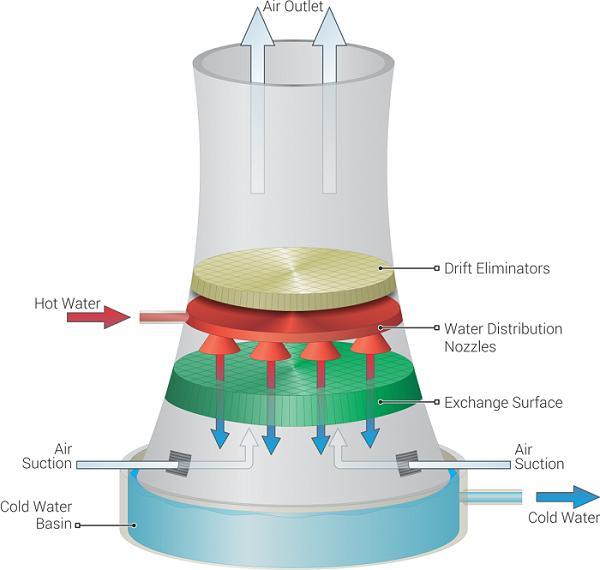

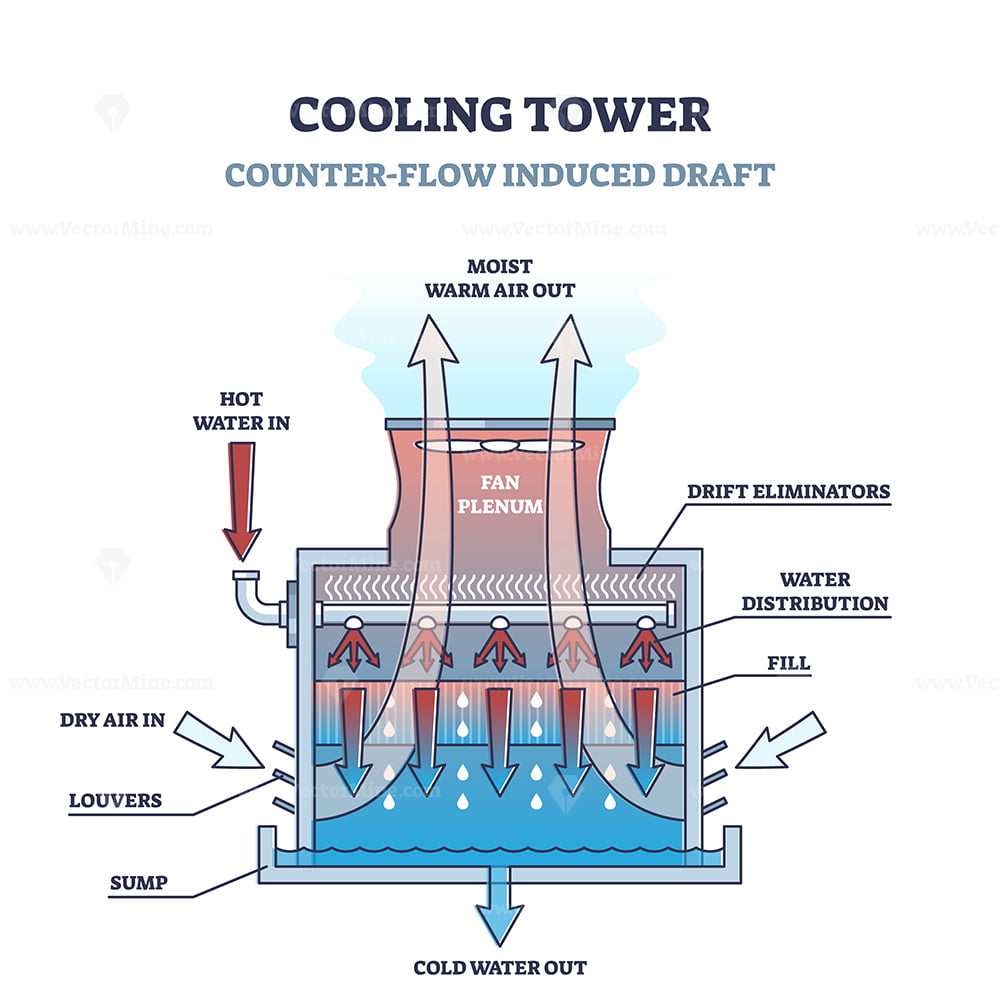

Cooling Tower Diagram A Go To Guide To Learn About Their Function Sequence of operation. when the operating fan(s) are operating at 50 percent speed, an additional fan shall be enabled and controlled at the same speed as the operating fans until all active cooling tower cell fans are enabled. when operating fans are running at minimum speed and the tower supply water temperature is five (5) degrees below the. Cooling tower air flowing past fill packaging. combining the spray of water, the thin film of water on the fill packaging and the flow of cool air you get a great amount of heat transfer. flow of air and condenser water. just to recap. warm condenser water enters the tower and is sprayed over the fill packaging. A cooling tower is an essential component of many industrial processes that generate heat. it is used to remove excess heat from the system and maintain the operating temperature at an optimal level. a cooling tower process flow diagram illustrates the various stages and components involved in the cooling tower operation. The water is exposed to air as it flows throughout the cooling tower. the air is being pulled by an motor driven electric “cooling tower fan”. when the air and water come together, a small volume of water evaporates, creating an action of cooling. the colder water gets pumped back to the process equipment that absorbs heat or the condenser.

Cooling Tower Diagram A Go To Guide To Learn About Their Function A cooling tower is an essential component of many industrial processes that generate heat. it is used to remove excess heat from the system and maintain the operating temperature at an optimal level. a cooling tower process flow diagram illustrates the various stages and components involved in the cooling tower operation. The water is exposed to air as it flows throughout the cooling tower. the air is being pulled by an motor driven electric “cooling tower fan”. when the air and water come together, a small volume of water evaporates, creating an action of cooling. the colder water gets pumped back to the process equipment that absorbs heat or the condenser.

Cross Flow Cooling Tower Type Structure And Work Principle Outline

Comments are closed.