Engine Bolt Torque Chart Youtube

Engine Bolt Torque Chart Youtube About press copyright contact us creators advertise developers terms privacy policy & safety how works test new features nfl sunday ticket press copyright. Have you ever thought about what exactly it means to torque a bolt? what does that measurement mean and what are you trying to achieve by getting the torque.

How To Torque Small Engine Head Bolts Basic Pattern Info On 3 Long In this video tito paul shows the proper installation and tightening of cylinder head. 1 proofload is the published number that full size headed bolts are tested to. the bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is deemed to have passed. for bolting specifications that do not have a published proofload, it is usually calculated at 92% of minimum yield strength. To ensure the correct torque is applied to the head bolts of your briggs and stratton engine, follow these steps: 1. clean the head bolt threads and the corresponding bolt holes thoroughly to remove any dirt, debris, or old thread locking compound. 2. apply a small amount of engine oil or assembly lubricant to the head bolt threads for smooth. If you use after market performance bolts like arp’s, you should follow the recommended torque specifications. 260, 289, 302 torque spec. 351w torque spec. 351c, 351m torque spec. 40 45 ft lbs. (45 50 ft lbs. for boss 351c) 105 ft lbs. (125 ft lbs. for boss 351c) 360, 390, 406, 427, 428fe torque spec.

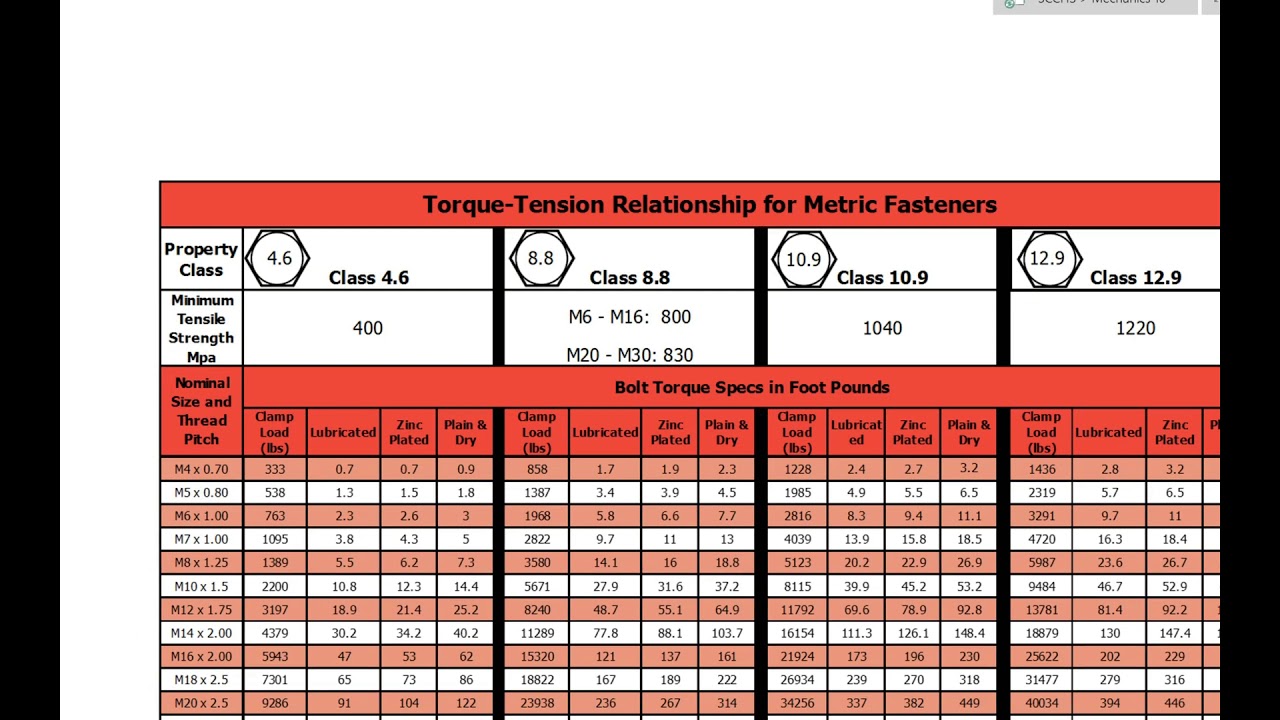

Engine Bolt Torque Chart To ensure the correct torque is applied to the head bolts of your briggs and stratton engine, follow these steps: 1. clean the head bolt threads and the corresponding bolt holes thoroughly to remove any dirt, debris, or old thread locking compound. 2. apply a small amount of engine oil or assembly lubricant to the head bolt threads for smooth. If you use after market performance bolts like arp’s, you should follow the recommended torque specifications. 260, 289, 302 torque spec. 351w torque spec. 351c, 351m torque spec. 40 45 ft lbs. (45 50 ft lbs. for boss 351c) 105 ft lbs. (125 ft lbs. for boss 351c) 360, 390, 406, 427, 428fe torque spec. What is bolt torque sequence? bolt tightening sequences is when a pattern of bolts is tightened to the necessary tension. to lessen the amount of pre load lost in a bolt as a result of elastic interactions, the bolts are tightened in a symmetrical pattern. typically, a torque wrench is used to apply torque to a bolt. a bolt that has pre load. Steps to torque briggs and stratton head bolts. follow these steps to properly torque the head bolts on your briggs and stratton engine: ensure that the engine is cool and not running. clean the cylinder head and the threads of the head bolts to remove any dirt or debris. refer to the engine model and the corresponding torque specifications.

Comments are closed.