Engine Bolt Torque Chart

Engine Bolt Torque Chart Youtube Make liter cid engine model year rod torque main torque cylinder head bolt torque allis chalmers 1.5 90 66 73 ft lbs 80 106 ft lbs 119 146 ft lbs allis chalmers 1.9 116 pin clamping bolt 35 40 ft lbs 65 ft lbs allis chalmers 1.9 116 35 40 ft lbs pin clamping bolt 35 40 ft lbs 80 ft lbs 65 ft lbs allis chalmers 2.0 120 60 ft lbs. 1 proofload is the published number that full size headed bolts are tested to. the bolt is stressed up to the proofload value, and if there is no deformation, elongation, or fracture, then the bolt is deemed to have passed. for bolting specifications that do not have a published proofload, it is usually calculated at 92% of minimum yield strength.

Engine Bolt Torque Chart Engine bolt torque specifications 426 hemi, rb, b, la engines. these specs are for stock type bolts with light engine oil applied to the threads and the underside of the bolt head. moly and other lubes offer reduced friction and increased bolt tension, which will affect the torque figure. if you use aftermarket performance bolts like arp’s. This repairengineering bolt torque chart was created assuming a value at the mid point of that range at 75% of the material proof strength. bolt proof load is defined as the maximum force that the material can support without experiencing permanent deformation. although material properties vary, an approximate estimate of proof strength is. Use hardened steel washers when installing aluminum cylinder heads. this will prevent galling of the soft aluminum. check the accuracy of your torque wrench and recalibrate, if necessary, before bolting down your cylinder heads. and finally, follow these torque sequences for your engine: source: fel pro. graphic by: lori sams. Gen 3 hemi torque specs. the torque specs are fairly similar between the gen 3 hemi engines. however, there are some differences. please see the chart below for some of the critical torque specs for your engine. starting with the center main cap and working your way out, tighten each m12 bolt ;to 20 ft. lbs. once that is done, repeat the same.

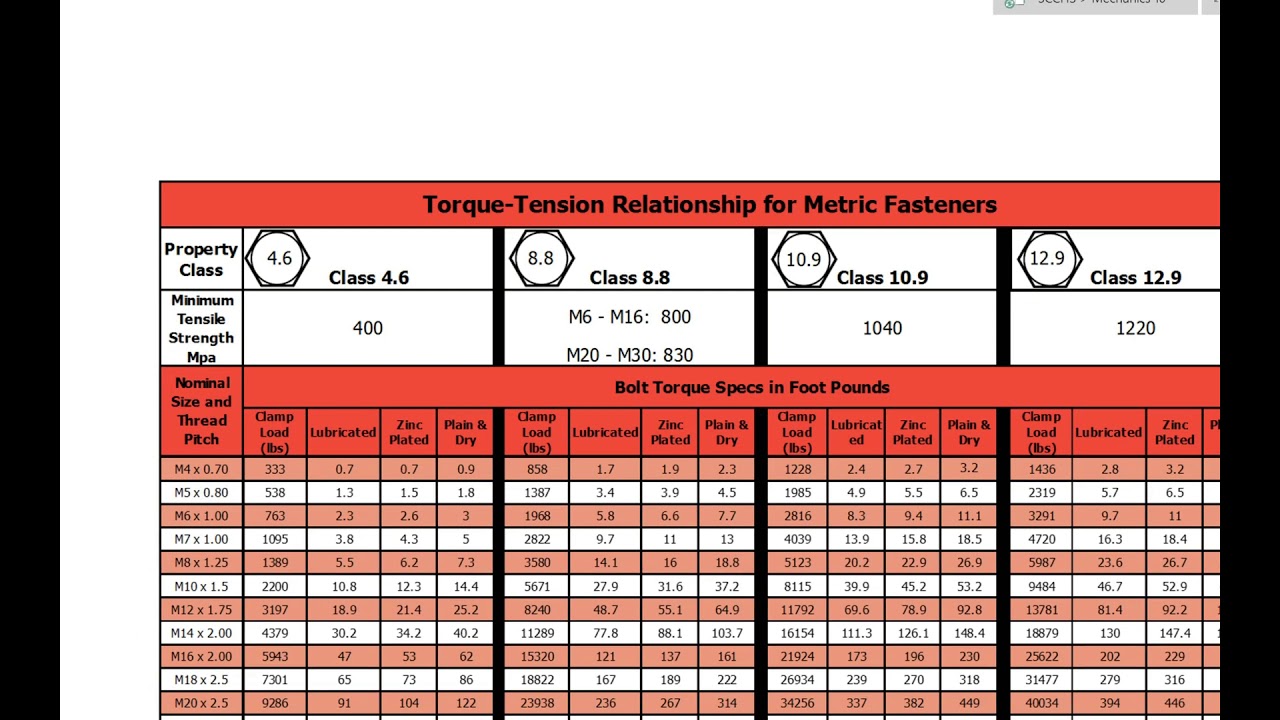

Engine Torque Specification Chart Use hardened steel washers when installing aluminum cylinder heads. this will prevent galling of the soft aluminum. check the accuracy of your torque wrench and recalibrate, if necessary, before bolting down your cylinder heads. and finally, follow these torque sequences for your engine: source: fel pro. graphic by: lori sams. Gen 3 hemi torque specs. the torque specs are fairly similar between the gen 3 hemi engines. however, there are some differences. please see the chart below for some of the critical torque specs for your engine. starting with the center main cap and working your way out, tighten each m12 bolt ;to 20 ft. lbs. once that is done, repeat the same. Torque tension reference guide printed in u.s.a. • supply part number: 9702365 • as 06 14 torque poster for additional technical information, contact fastenal engineering at engineer@fastenal . nominal dia. (in.) threads per inch 307a astm a307 grade a sae j429 grade 5 sae j429 grade 8 f n l g 9 fnl grade 9 clamp load (lbs.) tightening. Standard metric bolt dimensions and grades. torque values. applications (engine) applications (generator) view and download the chart here. standard metric bolt dimensions and grades visual see below torque values applications (engine) name size (163 224cc) nm ft lb. size (270 459cc) nm ft lb. connecting rod bolt m7 12 9 m8 18 13 cylin….

Comments are closed.