Digital Twin Aids In Virtual Commissioning Control Design

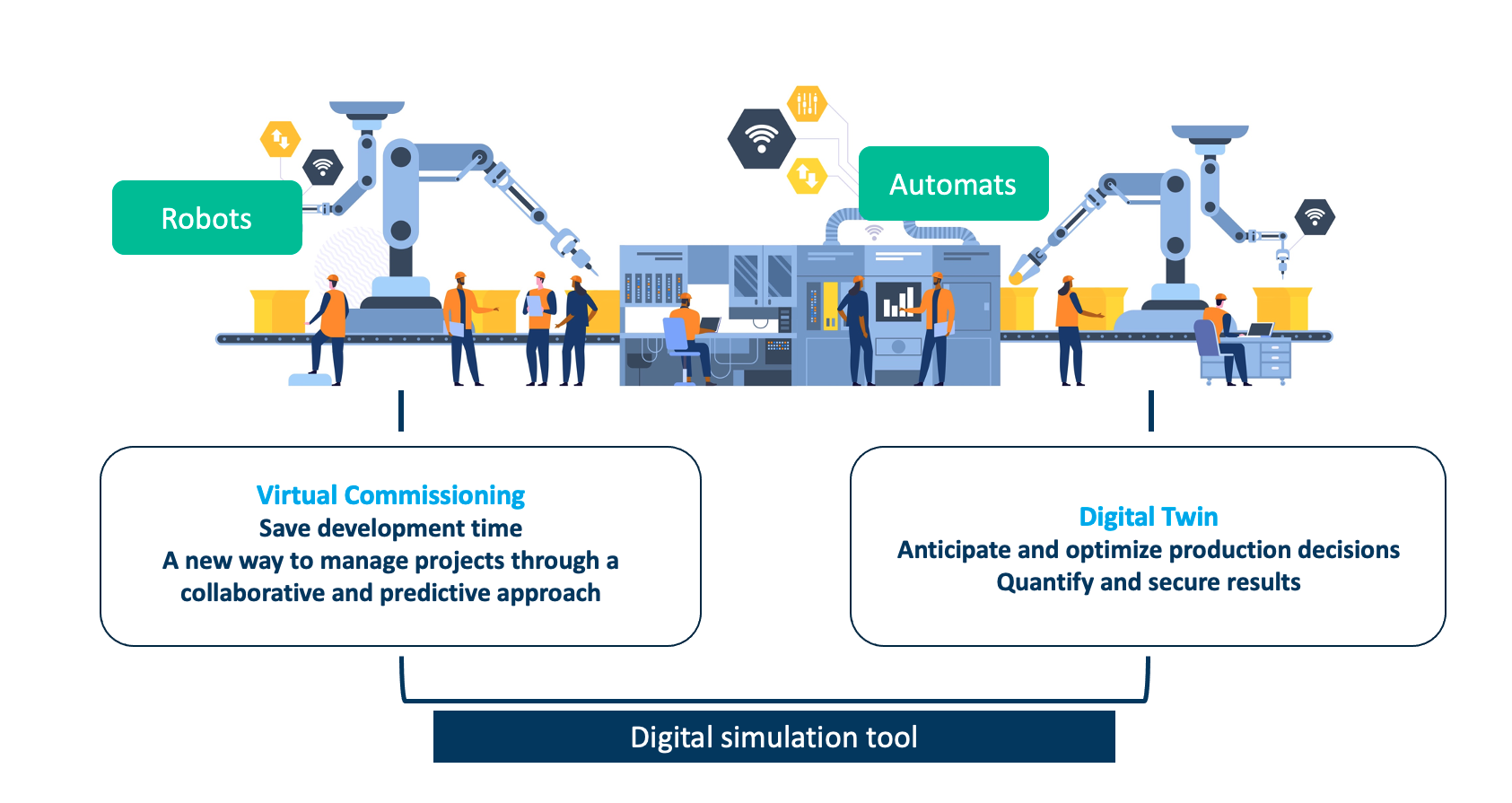

Creating A Digital Twin With Maplesim Virtual commissioning helps you avoid these risks by identifying potential issues earlier. it uses a simulated digital twin of your machine to perform controls testing before the machine is on site or maybe even before it’s built. a digital twin of your machine also offers value once a machine is deployed. Virtual commissioning allows engineers to connect the digital twin to the plc to test, refine and optimize mechanical, electrical and logical designs, and the integration between them, well before hardware is assembled on the shop floor, without the need to delay delivery or stop production. what virtual commissioning provides.

Virtual Commissioning And The Digital Twin вђ Minimizing Risk In The industry 4.0 machine architecture is based entirely on digital twins. thanks to their standardised communication interfaces, they make life easier for our customers throughout virtually the entire lifecycle of a machine: from virtual commissioning and control of the machine to data acquisition and the resulting value added services such as. Virtually test control strategies before physical commissioning. maplesoft products and services are used in machine design, robotics, aerospace, automotive and many other fields where engineers face complex challenges. customers include boeing, flsmidth, ford, google, intel, nasa and samsung. digital twins and virtual commissioning. 1.3 virtual commissioning within digital twin architectures. virtual commissioning (vc) is generally utilized for the design and verification of the control software of complex manufacturing systems due to its ability to speed up the commissioning process . in the context of dt, vc has been utilized within the robotics domain as a synchronized. Virtual commissioning involves the testing, verification, and validation of automation control systems through the utilisation of a digital representation of the automation equipment and facility. this process takes place in a simulated environment, leading to a decrease in the amount of commissioning activities that need to be carried out in the physical commissioning.

Virtual Commissioning It S Not Too Late To Make The Right Choice 1.3 virtual commissioning within digital twin architectures. virtual commissioning (vc) is generally utilized for the design and verification of the control software of complex manufacturing systems due to its ability to speed up the commissioning process . in the context of dt, vc has been utilized within the robotics domain as a synchronized. Virtual commissioning involves the testing, verification, and validation of automation control systems through the utilisation of a digital representation of the automation equipment and facility. this process takes place in a simulated environment, leading to a decrease in the amount of commissioning activities that need to be carried out in the physical commissioning. Tual commissioning with a model driven digital twin in the manufacturing and automation industry, adopting new development techniques has become a key requiremen. for success in a highly evolving, competitive market. as demands on product requirements increase, the inherent design risks can pose significant problems, threatening t. The virtual commissioning component can also integrate with the digital twin to further streamline the commissioning testing process. “modern advanced digital twins have the capability to integrate 3d models, static attribute data, live process data, or simulated process data into a single cohesive view,” mustard said.

A Digital Twin For Low Risk Virtual Commissioning Tual commissioning with a model driven digital twin in the manufacturing and automation industry, adopting new development techniques has become a key requiremen. for success in a highly evolving, competitive market. as demands on product requirements increase, the inherent design risks can pose significant problems, threatening t. The virtual commissioning component can also integrate with the digital twin to further streamline the commissioning testing process. “modern advanced digital twins have the capability to integrate 3d models, static attribute data, live process data, or simulated process data into a single cohesive view,” mustard said.

Virtual Commissioning The Perfect Starting Point For Digital Twinning

Comments are closed.