Data Analytics In Manufacturing What Is It Top Use Cases And

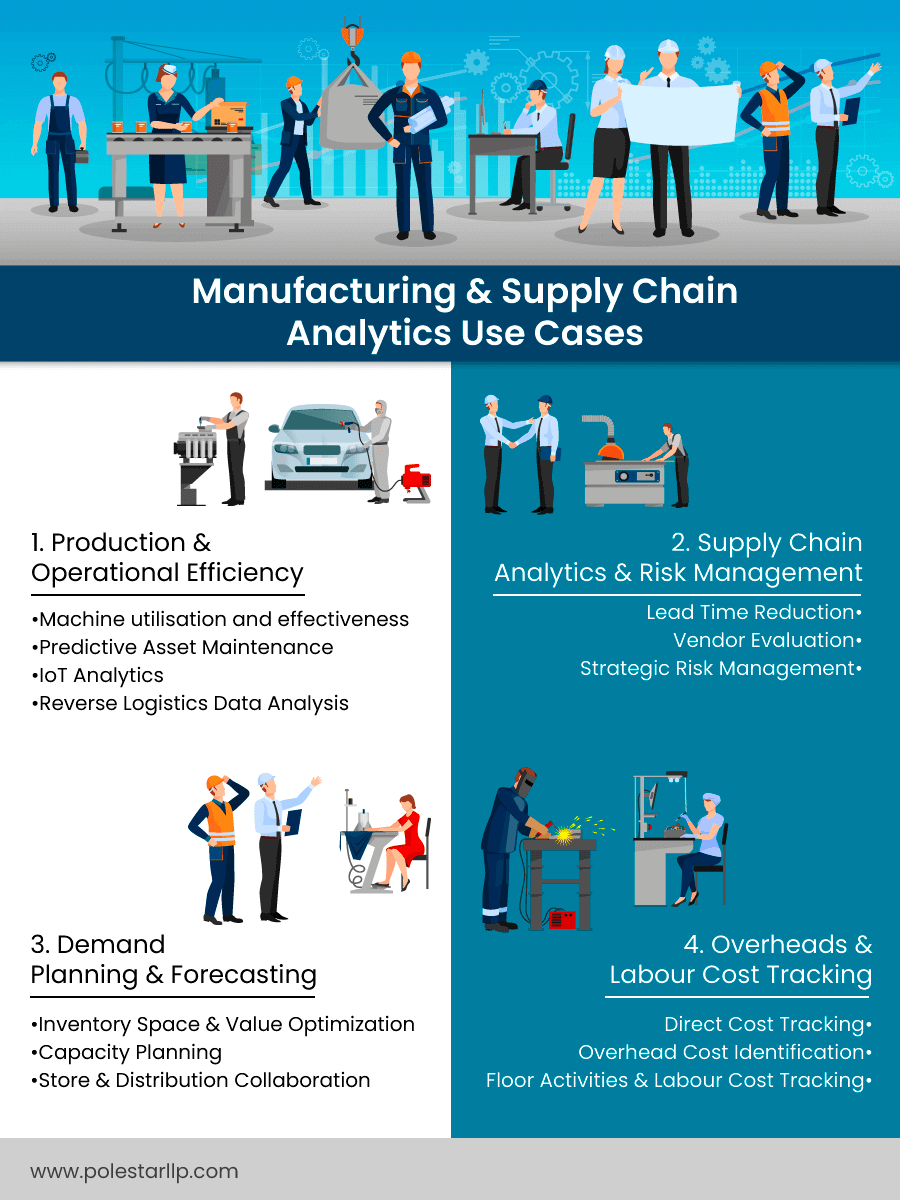

Manufacturing Supply Chain Analytics Use Cases Polestar Solutions Data analytics in manufacturing industry uses machine, operational, and system data to manage and optimize production, including key functions such as maintenance, quality, and planning. with accurate and real time data, manufacturers can make better, faster decisions. manufacturers have used data to improve efficiency and advance their market. Manufacturing analytics is the use of machine, operational, and system data to manage and optimize production, including key functions such as maintenance, quality, and planning. with accurate and real time data, manufacturers can make better, faster decisions. manufacturers have used data analysis to improve efficiency and advance their market.

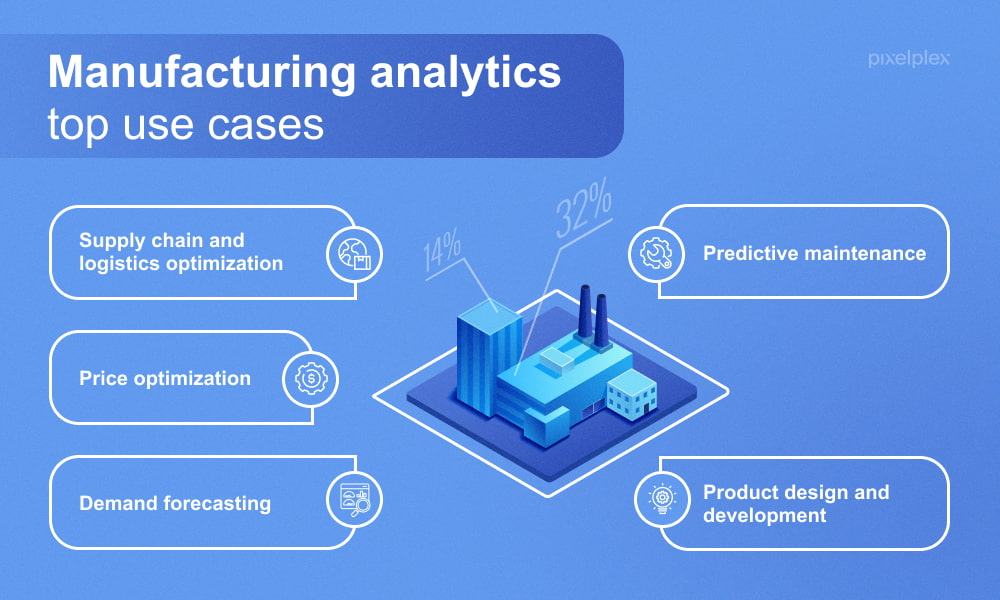

Overview Of Top 5 Manufacturing Analytics Use Cases The manufacturing industry can benefit from data analytics in many ways. some prominent use cases are predicting maintenance needs and forecasting demand. leveraging data analytics tools enables businesses to gain insights, optimize operations, and improve their bottom line. Big data analytics for manufacturing processes. source: science direct what are the use cases of manufacturing analytics? manufacturing processes produce a large volume of data from: machines: robotics, sensors, actuators, iot devices, etc. operators: erp, sales, logistics, etc. this data can be collected and analytics can be applied to it for. The manufacturing industry is on the verge of a data‑driven revolution. companies are collaborating in hyperconnected value networks, using data‑and‑analytics applications to drive productivity, develop new customer experiences and improve the societal and environmental impact of companies. this technological advance has come at a time of. Step 1: ingestion of the data from the data source. step 2: process and enrich the data so your downstream system can utilize them in the format it understands the best. step 3: store the data into a data warehouse or data lake for either long term archival or for reporting and analysis.

Data Analytics In Manufacturing What Is It Top Use Cases And The manufacturing industry is on the verge of a data‑driven revolution. companies are collaborating in hyperconnected value networks, using data‑and‑analytics applications to drive productivity, develop new customer experiences and improve the societal and environmental impact of companies. this technological advance has come at a time of. Step 1: ingestion of the data from the data source. step 2: process and enrich the data so your downstream system can utilize them in the format it understands the best. step 3: store the data into a data warehouse or data lake for either long term archival or for reporting and analysis. Check out the nine use cases of analytics in the manufacturing sector. 1. operational equipment effectiveness control. collect data from machines and smart sensors installed on a production floor. analyze the data to measure the operational equipment effectiveness (oee) for machines or plant cells. Your manufacturing equipment generates valuable data and feeds it to the analytical software tools. your software can be coded to help the processes with useful data, and it can even ignore the useless information that comes from sensors or machinery. data analytics software in manufacturing industry can boost process quality, efficiency, and.

Data Analytics In Manufacturing What Is It Top Use Cases And Check out the nine use cases of analytics in the manufacturing sector. 1. operational equipment effectiveness control. collect data from machines and smart sensors installed on a production floor. analyze the data to measure the operational equipment effectiveness (oee) for machines or plant cells. Your manufacturing equipment generates valuable data and feeds it to the analytical software tools. your software can be coded to help the processes with useful data, and it can even ignore the useless information that comes from sensors or machinery. data analytics software in manufacturing industry can boost process quality, efficiency, and.

Comments are closed.