Creating A Haccp Plan What Your Organization Needs To Ensure Food Safety

Why Is Haccp Important To Your Food Establishment Principle #1: conduct a hazard analysis. an effective hazard analysis involves listing down the steps in the production process and identifying the hazards associated with each task performed. afterwards, the haccp team should assess the severity, significance, and frequency of the risk and set preventive measures. The first step in creating a haccp plan is to put together a team of individuals who have specific knowledge and expertise in your product and process. this team should be interdisciplinary and draw on expertise from different fields including engineering, production, sanitation, quality assurance, and food science.

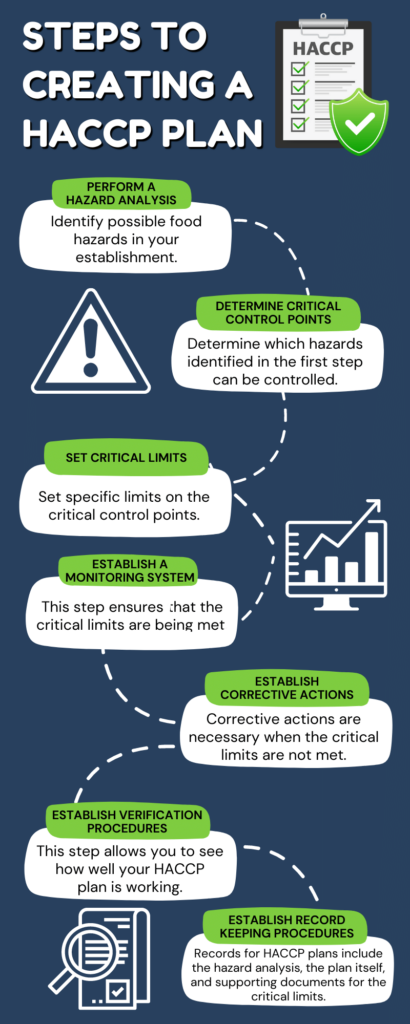

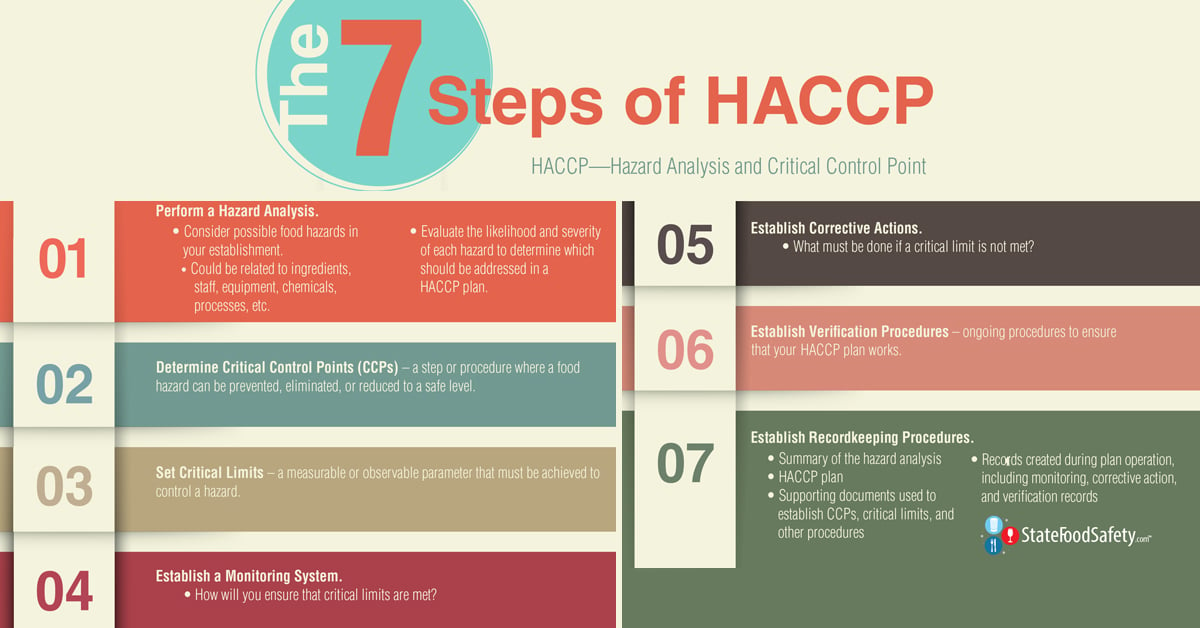

Haccp Food Safety Chart Perform as expected to achieve the intended food safety objective (9 cfr 417.4 (a)(1). on going verification: activities such as calibration, direct observation, and review of records as well as other independent checks such as testing designed to ensure the haccp system is functioning as intended on an ongoing basis. developing a haccp plan. Haccp is a systematic approach to the identification, evaluation, and control of food safety hazards based on the following seven principles: principle 1: conduct a hazard analysis. principle 2. Principle 1: conduct a hazard analysis. you should begin any major process in your food processing business by first conducting a hazard analysis. a hazard analysis involves identifying the most significant hazards as well as where they are most likely to occur in each step of the production process. Haccp stands for hazard analysis and critical control points. according to the fda, haccp is a management framework that ensures food safety by regularly evaluating and controlling biological, chemical, and physical hazards at any stage of food production and the supply chain. a haccp plan lets you control every step and process at your food.

Building Out Your Haccp Plan With The 7 Principles Images Principle 1: conduct a hazard analysis. you should begin any major process in your food processing business by first conducting a hazard analysis. a hazard analysis involves identifying the most significant hazards as well as where they are most likely to occur in each step of the production process. Haccp stands for hazard analysis and critical control points. according to the fda, haccp is a management framework that ensures food safety by regularly evaluating and controlling biological, chemical, and physical hazards at any stage of food production and the supply chain. a haccp plan lets you control every step and process at your food. Haccp principle #1 – perform a hazard analysis. the hazard analysis is the step where the haccp team scrutinizes the production process and documents where and how any hazards can be introduced to the food process. food safety hazards are either biological, chemical, or physical. haccp principle #1 is perhaps the most important step in. Haccp stands for hazard analysis critical control points (haccp). haccp is an internationally recognized method of identifying and managing food safety related risk and, when central to an active food safety program, can provide your customers, the public, and regulatory agencies assurance that a food safety program is well managed.

Comments are closed.