Cooling Tower Layout Diagram

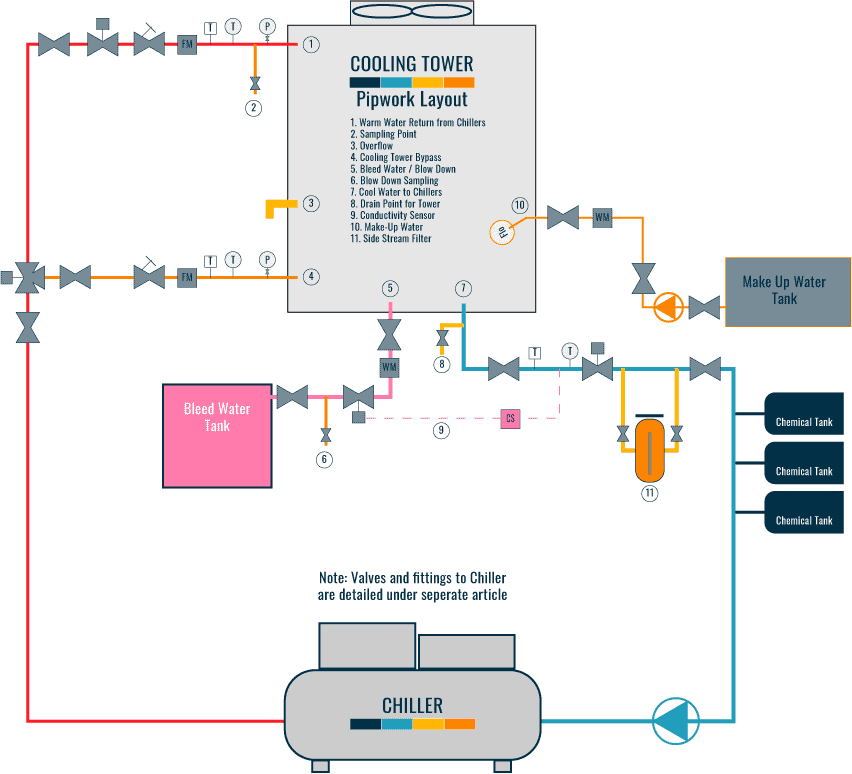

Cooling Tower Piping Layout And Diagrams Constructandcommission Cooling tower | piping layout and diagrams. to allow the cooling towers to operate correctly, in line with the design and efficiently, various systems will need to be connected to allow them to work. depending upon how the towers are installed will mean different configurations would be required. the pipework that is commonly connected to the. A cooling tower flow diagram helps visualise the complex system of the tower and its components. the diagram illustrates the flow of water and air through the tower, as well as the different stages of the cooling process. the cooling tower flow diagram typically begins with the entry of hot water from the industrial process into the tower.

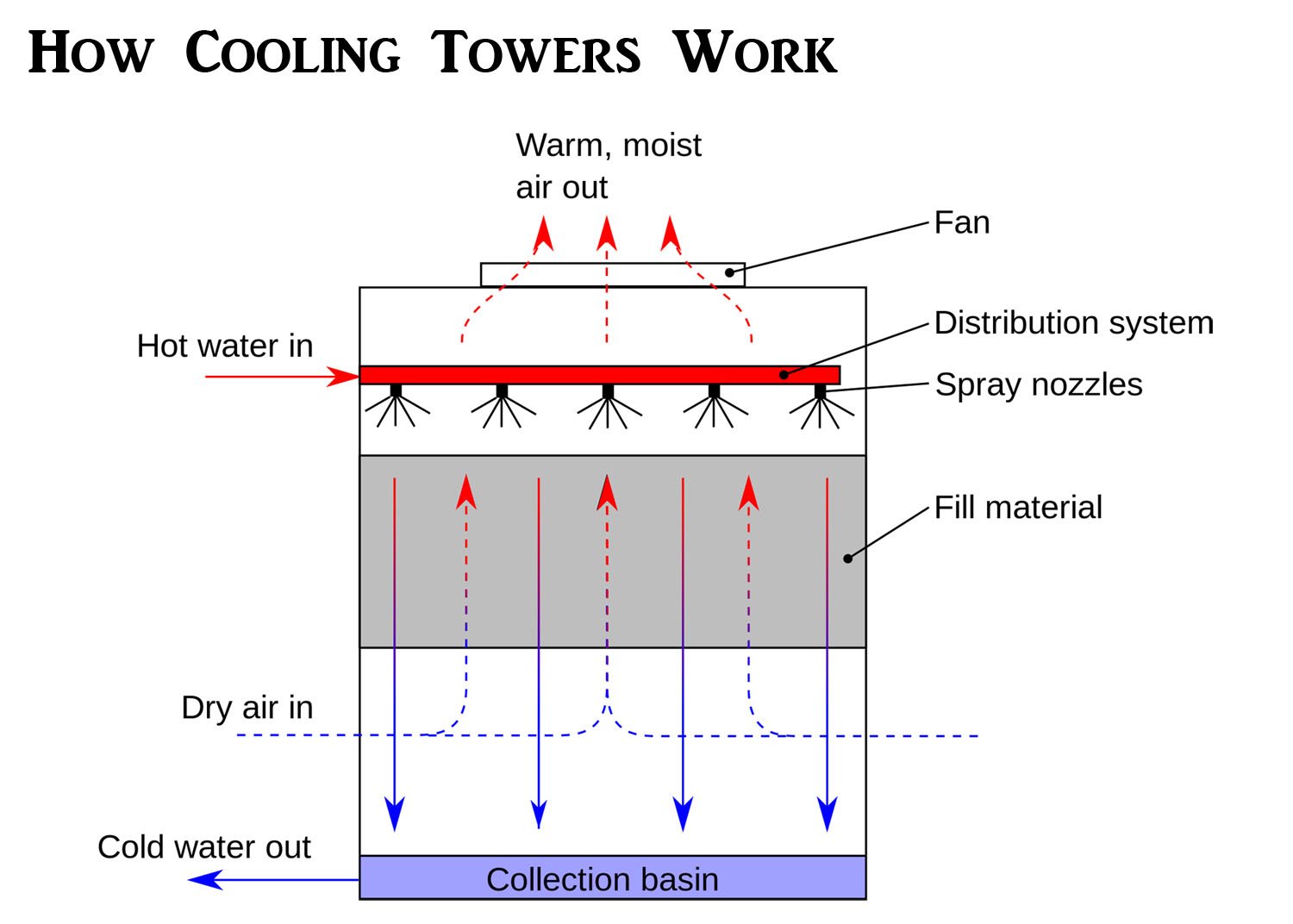

How Cooling Towers Work W Diagram Pictures Principles 2018 Counterflow cooling tower diagram difference between crossflow and counterflow cooling towers: in counterflow cooling tower system processes, the air vertically flows upwards, counter to the water flow in the fill media. due to the air flowing vertically, it's not possible to use the basin's gravity flow like in crossflow towers. Section 1 – evaporative cooling towers an evaporative cooling tower is a heat exchanger that transfers heat from circulating water to the atmosphere. warm water from the heat source is pumped to the top of the tower and then flow down through plastic or wooden shells. as it falls downward . cooling towers – m07 001 3. Sequence of operation. when the operating fan(s) are operating at 50 percent speed, an additional fan shall be enabled and controlled at the same speed as the operating fans until all active cooling tower cell fans are enabled. when operating fans are running at minimum speed and the tower supply water temperature is five (5) degrees below the. Understanding the basics of piping and controls is step number one in the cooling tower industry. but how effectively a cooling tower piping system is designed and installed can have a critical impact on system efficiency, functionality and even safety. properly engineered condenser, chiller and cooling tower piping and controls will improve heat transfer and avoid problems such as air.

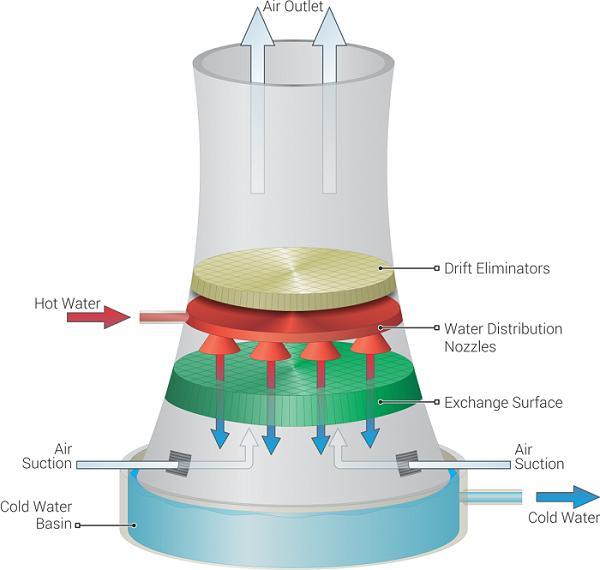

Cooling Tower Piping Layout And Diagrams Constructandcommission Sequence of operation. when the operating fan(s) are operating at 50 percent speed, an additional fan shall be enabled and controlled at the same speed as the operating fans until all active cooling tower cell fans are enabled. when operating fans are running at minimum speed and the tower supply water temperature is five (5) degrees below the. Understanding the basics of piping and controls is step number one in the cooling tower industry. but how effectively a cooling tower piping system is designed and installed can have a critical impact on system efficiency, functionality and even safety. properly engineered condenser, chiller and cooling tower piping and controls will improve heat transfer and avoid problems such as air. Product: cooling towers – free cooling operation date: april 16, 2010 table of contents section page i. introduction background 2 ii. system design considerations: cooling tower selection 5 unit layout 6 cooling tower piping 7 cooling tower accessories 8 iii. capacity control methods 10. Cooling tower air flowing past fill packaging. combining the spray of water, the thin film of water on the fill packaging and the flow of cool air you get a great amount of heat transfer. flow of air and condenser water. just to recap. warm condenser water enters the tower and is sprayed over the fill packaging.

Cooling Tower Diagram A Go To Guide To Learn About Their Function Product: cooling towers – free cooling operation date: april 16, 2010 table of contents section page i. introduction background 2 ii. system design considerations: cooling tower selection 5 unit layout 6 cooling tower piping 7 cooling tower accessories 8 iii. capacity control methods 10. Cooling tower air flowing past fill packaging. combining the spray of water, the thin film of water on the fill packaging and the flow of cool air you get a great amount of heat transfer. flow of air and condenser water. just to recap. warm condenser water enters the tower and is sprayed over the fill packaging.

Comments are closed.