Broaching Gun Barrel Rifling

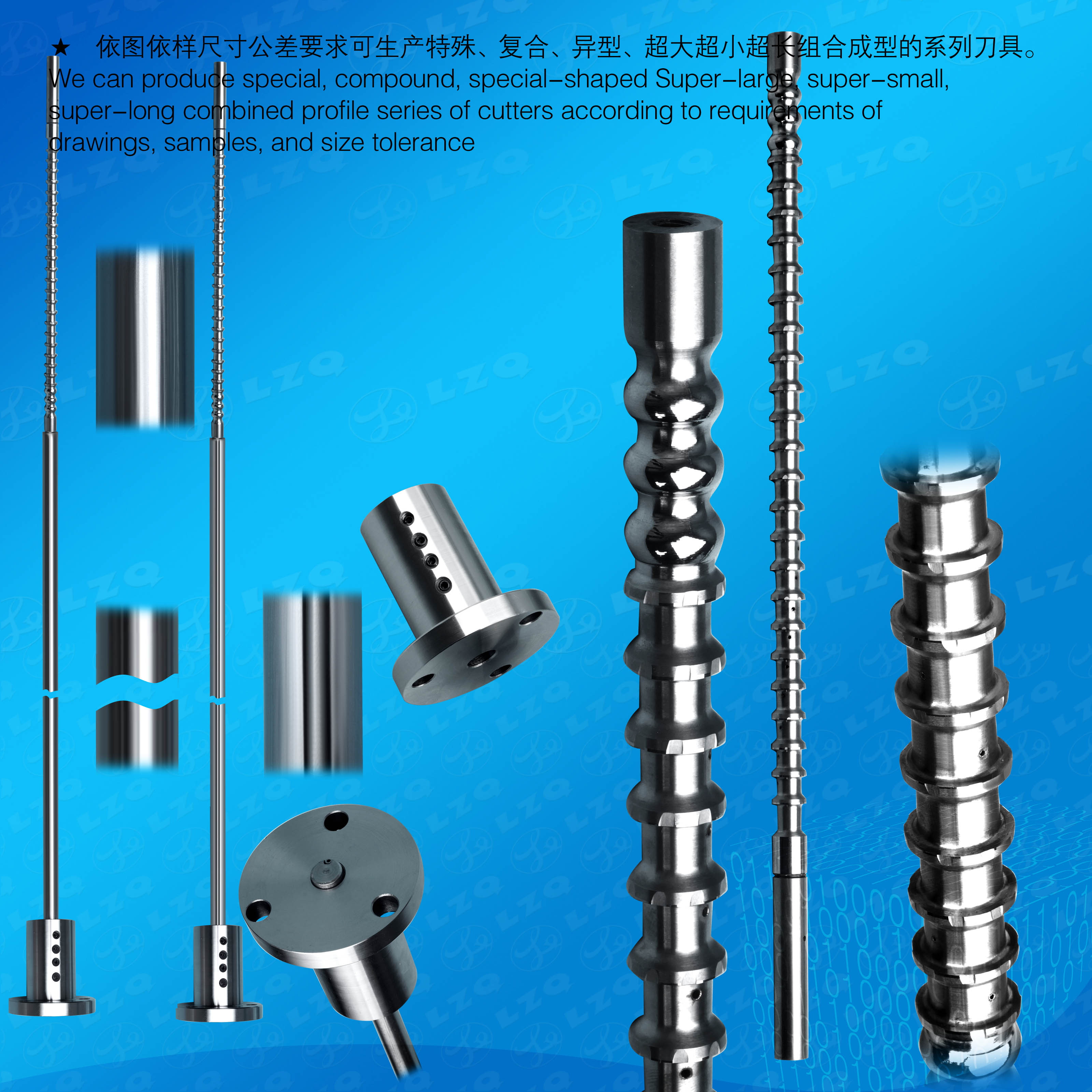

Rifling Bore Broach Lzq Tool Co Ltd Support nra family donate. there are five barrel rifling methods in general use: cut, button, broach, hammer forging and ecm (electrolytic cationic machining). all have their benefits. today, we'll cover the first three methods. 1. cut rifling. cut rifling is the oldest method of rifling a gun barrel. the cut rifling method removes metal from. Broach rifled barrels may be contoured after rifling. hammer forged rifling hammer forging is an ultra modern method of rifling a gun barrel that is well suited to high volume production by.

Broaching Gun Barrel Rifling Youtube Each barrel rifling technique serves a unique purpose, influenced by factors such as the intended use of the firearm, production efficiency, and cost considerations. button and broach rifling are often favored for their efficiency in mass production, while cut rifling remains the choice for applications demanding the highest precision. Step 1: the bore is made. before you can rifle a barrel you have to have a bore to rifle. bores are made by drilling through the middle of the barrel. this is one of the steps where absolute precision is critical. trying a gun drill to hole down through the middle of a solid chrome moly steel rod is tricky unless you have advanced equipment to. Cut rifling is a precise and time consuming process, but it produces a high quality rifling pattern that is essential for accurate shooting. step. description. image. 1. the barrel blank is turned on a lathe to create a cylindrical shape. 2. a cutting tool with a helical shape is used to cut grooves in the barrel. 3. The rifling of a barrel is the spiraling pattern of grooves inside of the gun barrel that imparts spin to the bullet as it travels from the chamber to the muzzle. the differences come in with the way the rifling is put into the barrel and how the lands and grooves (high and low spots) are machined into it, and the pattern of lands and grooves.

Comments are closed.