5 Axis Machining An Aerospace Structural Part

5 Axis Machining Aerospace Structural Part Grob Cam Software This video shows the machining of a structural part for the aerospace industry on a grob g352. it was machined in one setup using highly efficient roughing a. How 5 axis machining supports aerospace part production. the major benefit is the ability to machine features on multiple faces and at angles other than 90° without removing and refixturing the part. this saves time and improves accuracy. it also reduces lead time because batches of parts aren’t queuing for a series of machining operations.

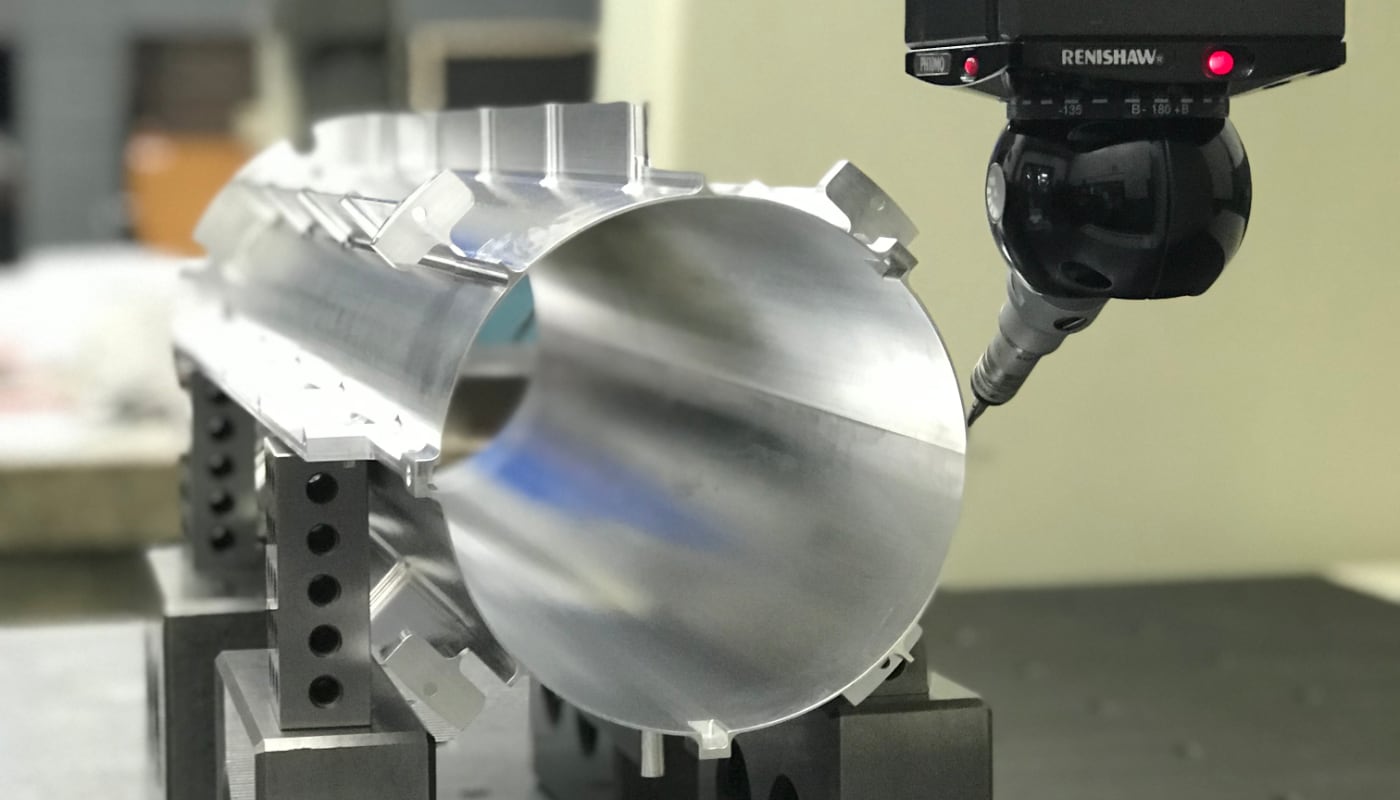

Large 5 Axis Machining Precision Advanced Machining 5 axis machining in the aerospace industry. in the aerospace industry, 5 axis machining has become increasingly popular. this technology enables the production of complex parts and components with high precision, accuracy, and efficiency. with 5 axis machining, we can produce difficult or impossible parts through traditional manufacturing. 5 axis cnc machining is useful for a wide range of aerospace applications, from turbine blades to engine components and beyond. one of the main advantages of 5 axis machining is its ability to create parts with more intricate shapes and features, making it ideal for use in complex aerospace applications where precision and accuracy are paramount. In conclusion, aerospace cnc machining is a critical player in the aerospace industry, ensuring the safety, reliability, and efficiency of aircraft and spacecraft. its role in creating high precision, quality parts is undeniable, and as aerospace technology continues to advance, the importance of precision machining in this industry will only grow. Efficient production of aircraft structural parts . aircraft structural parts, such as fuselage frames and wing ribs, demand precision and strength. 5 axis machining enables manufacturers to produce these components with the utmost accuracy, ensuring perfect alignment and reducing assembly time. the result is a stronger and lighter aircraft.

5 Axis Machining An Aerospace Structural Part Youtube In conclusion, aerospace cnc machining is a critical player in the aerospace industry, ensuring the safety, reliability, and efficiency of aircraft and spacecraft. its role in creating high precision, quality parts is undeniable, and as aerospace technology continues to advance, the importance of precision machining in this industry will only grow. Efficient production of aircraft structural parts . aircraft structural parts, such as fuselage frames and wing ribs, demand precision and strength. 5 axis machining enables manufacturers to produce these components with the utmost accuracy, ensuring perfect alignment and reducing assembly time. the result is a stronger and lighter aircraft. Applications of 5 axis machining. aerospace industry: the aerospace sector benefits greatly from 5 axis machining, as it allows for producing lightweight, intricate components that meet strict tolerances. turbine blades, engine components, and structural parts are often manufactured using this technology. One of the biggest reasons 5 axis machining is so prevalent in the world of aerospace is machine setup. the parts often have complex geometries that don’t easily lend to 3 or 4 axis operations. while many of the parts might be possible without five axes, you’d have to continuously refixture your part. in other words, you could only machine.

Comments are closed.