10 Tips For Troubleshooting Your Air Compressor

Air Compressor Troubleshooting Guide Pdf Chart And Tips There are a few key maintenance tips that you should follow in order to ensure your compressor runs effectively and efficiently. 1. check the oil level regularly: just like a car, an air compressor requires oil to run smoothly. ensure the oil level is adequate, and top up if necessary. 2. 10 essential tips for troubleshooting your air compressor. excessive noise in operation – when the compressor is operating more loudly than usual, it could be any number of issues such as a loose pulley, flywheel, belt, cooler, or accessories. tightening any of these could help. you may also want to add oil to the crankcase and check for any.

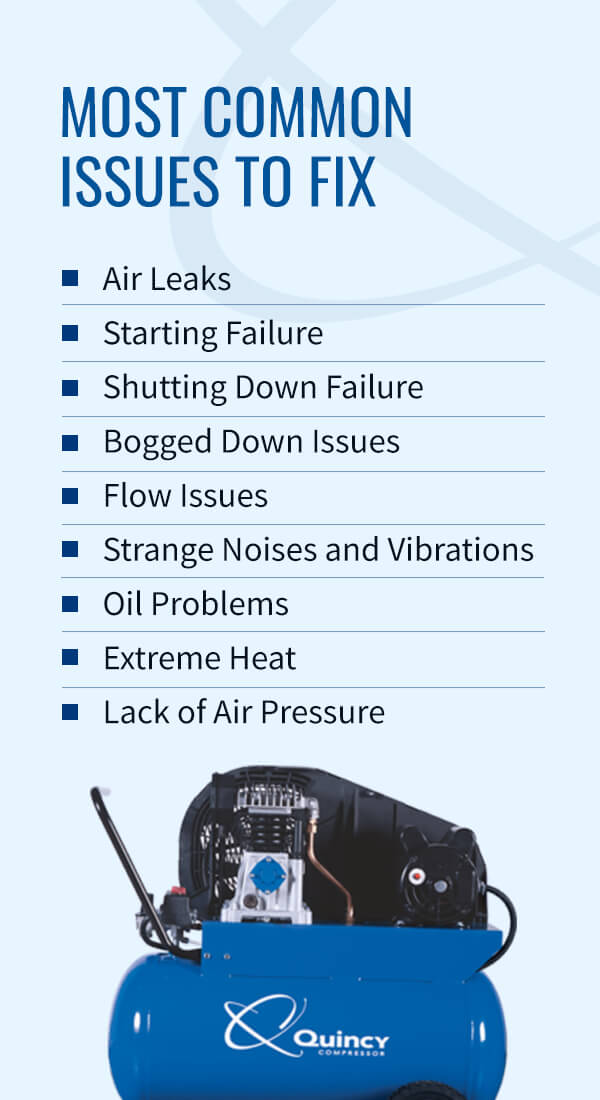

How To Fix An Air Compressor Quincy Compressor Here are some steps to take when diagnosing and resolving issues with an air compressor: 1. check for power: first, make sure the air compressor is connected to a power source and that the switch is turned on. if it is, check that the power cord and any other connections are firmly attached. 2. Step 1 – turn off the air compressor. step 2 – open the tank relief valve until the tank is drained to 30 psi or less (this will help force out liquid). step 3 – place a drain pan under the drain plug at the bottom of the tank. step 4 – slowly unscrew the drain plug and let the moisture drain out. Unplug the air compressor: always start by unplugging the compressor from the power source to prevent any electrical accidents. 2. release the pressure: find the pressure release valve, usually located on the side of the compressor, and turn it to release any air trapped in the compressor. 3. To check the oil level in your air compressor: look for the oil level sight glass or unscrew the cap to access the dipstick. the oil level should at least ½ of the way to slightly above halfway in the oil level sight glass or on the dipstick. if it appears that it is time for an oil change in your air compressor:.

Air Compressor Troubleshooting Chart Toals Roar Unplug the air compressor: always start by unplugging the compressor from the power source to prevent any electrical accidents. 2. release the pressure: find the pressure release valve, usually located on the side of the compressor, and turn it to release any air trapped in the compressor. 3. To check the oil level in your air compressor: look for the oil level sight glass or unscrew the cap to access the dipstick. the oil level should at least ½ of the way to slightly above halfway in the oil level sight glass or on the dipstick. if it appears that it is time for an oil change in your air compressor:. Check the air filter: a clogged air filter can reduce the efficiency of your compressor and cause it to overheat. make sure to replace the air filter regularly as per described maintenance interval. check the oil level: low oil levels can cause the compressor to overheat or seize up. make sure to check and top up the oil levels regularly. Start by unplugging the compressor. then, open the drain valve at the bottom of the tank to depressurize it. next, remove the 1 4 in. line going to the unloader valve, as shown in the photo here. use slip joint pliers or small pipe wrench to remove the quick connect fitting, pressure regulator and gauge from the pressure switch.

Troubleshooting Common Issues With Your Air Compressor Complete Guide Check the air filter: a clogged air filter can reduce the efficiency of your compressor and cause it to overheat. make sure to replace the air filter regularly as per described maintenance interval. check the oil level: low oil levels can cause the compressor to overheat or seize up. make sure to check and top up the oil levels regularly. Start by unplugging the compressor. then, open the drain valve at the bottom of the tank to depressurize it. next, remove the 1 4 in. line going to the unloader valve, as shown in the photo here. use slip joint pliers or small pipe wrench to remove the quick connect fitting, pressure regulator and gauge from the pressure switch.

Comments are closed.